Pouring spout seal for composite packagings

A technology of composite packaging and seals, which is applied in packaging, packaging protection, transportation and packaging, etc., and can solve problems such as insufficient tightness of seals and unsatisfactory repeated closures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

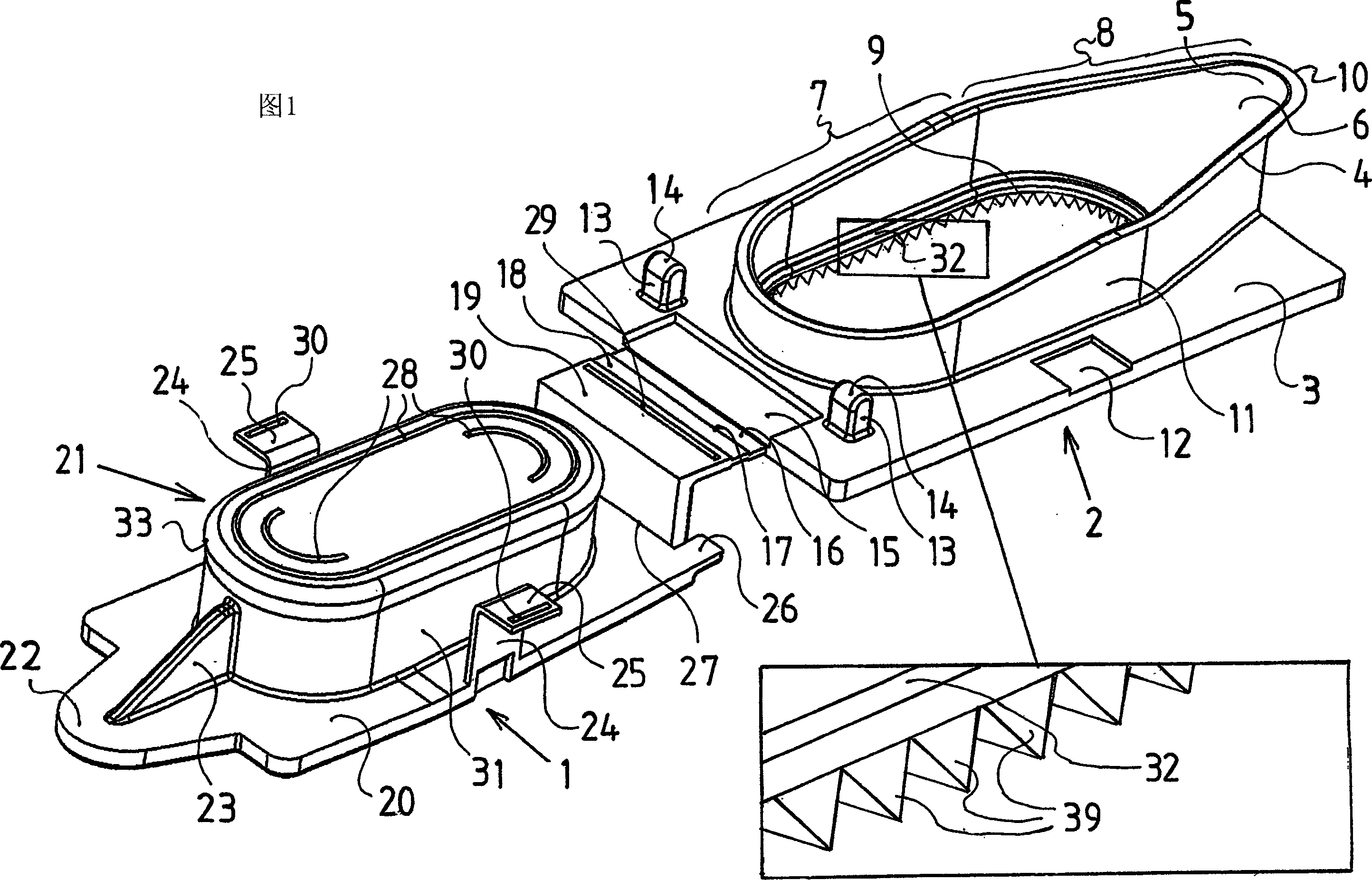

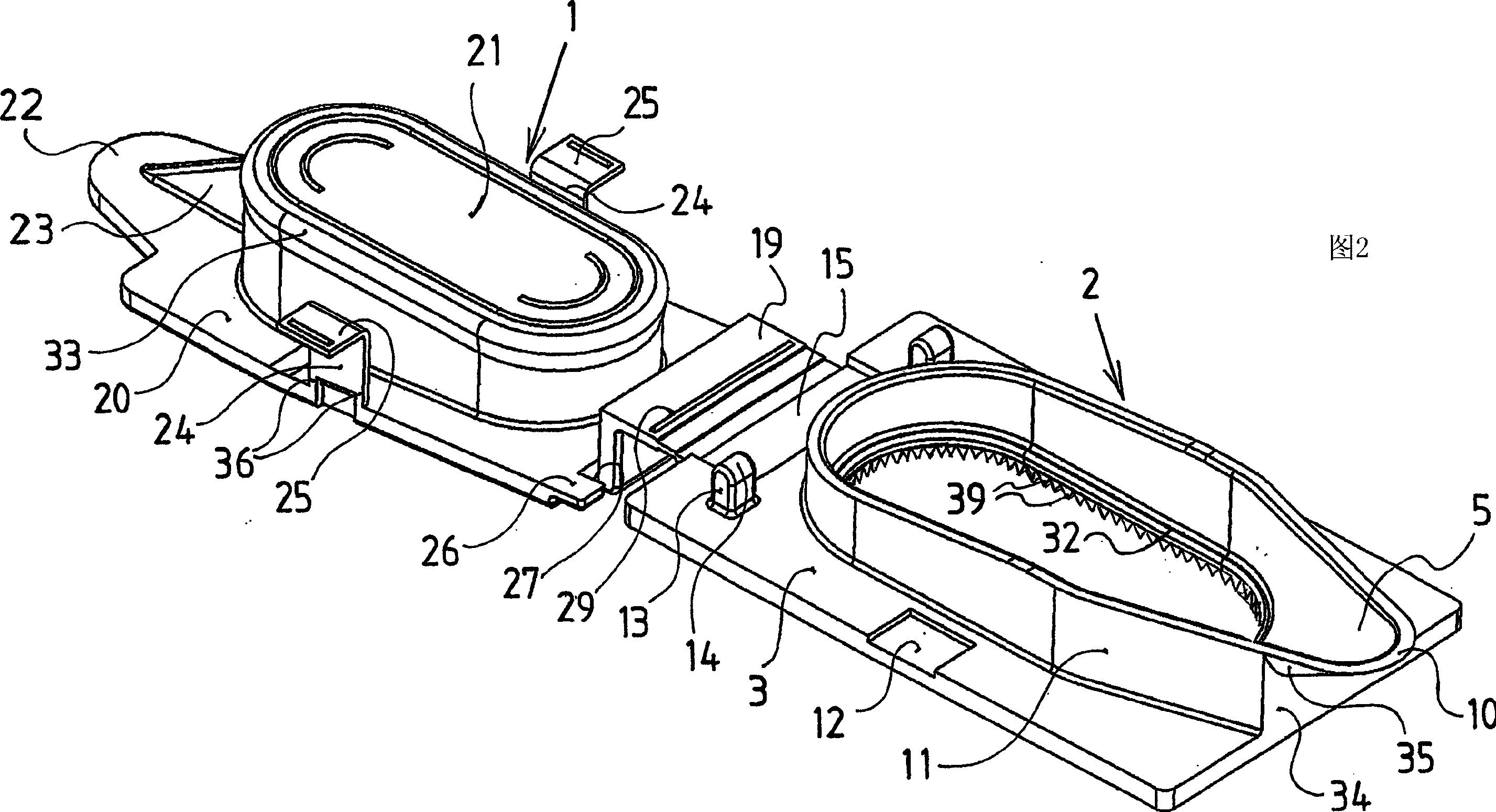

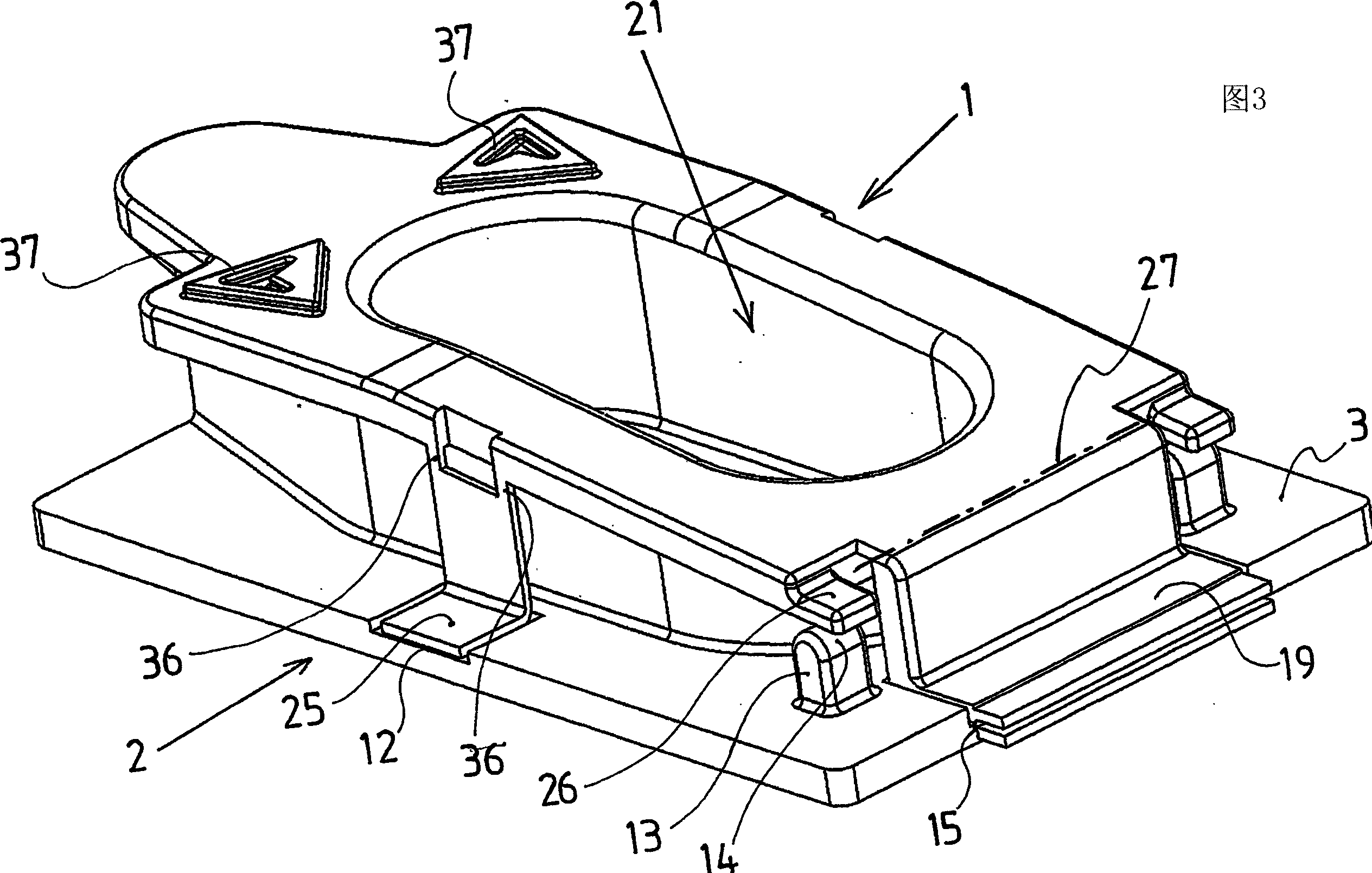

[0016]Accompanying drawing 1 has shown pouring spout lid with perspective view. In the drawings the cover 1 is located at the front and the bottom part 2 is located behind it. The bottom part 2 consists of a horizontal plate 3 on which an upwardly protruding overhang 11 having a flange 4 is molded. A pouring spout 5 is formed on the front side of the bottom part 2 (ie the side towards the rear in the figure) and has a wall 6 extending at an oblique angle relative to the disc 3 . The overhang 11 with the flange 4 rises from the side of the hinge at varying heights relative to the disk 3 , this elevation encompassing the entire area 7 , while the flange 4 in the front area 8 is parallel to the disk 3 alone extending horizontally, thereby forming the pouring spout. The flange 4 is thus higher than the other area 7 in the area 8 where the pouring spout 5 is located. The overhanging member 11 encloses an opening 9 in the height direction of the disc 3 , said opening area 9 is "O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com