Externally arranged automatic clutch engine

An automatic clutch and engine technology, applied in the direction of machine/engine, mechanical equipment, transmission control, etc., can solve the problems of small friction, sliding, not suitable for large-displacement engines, etc., to achieve high friction and large transmission torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

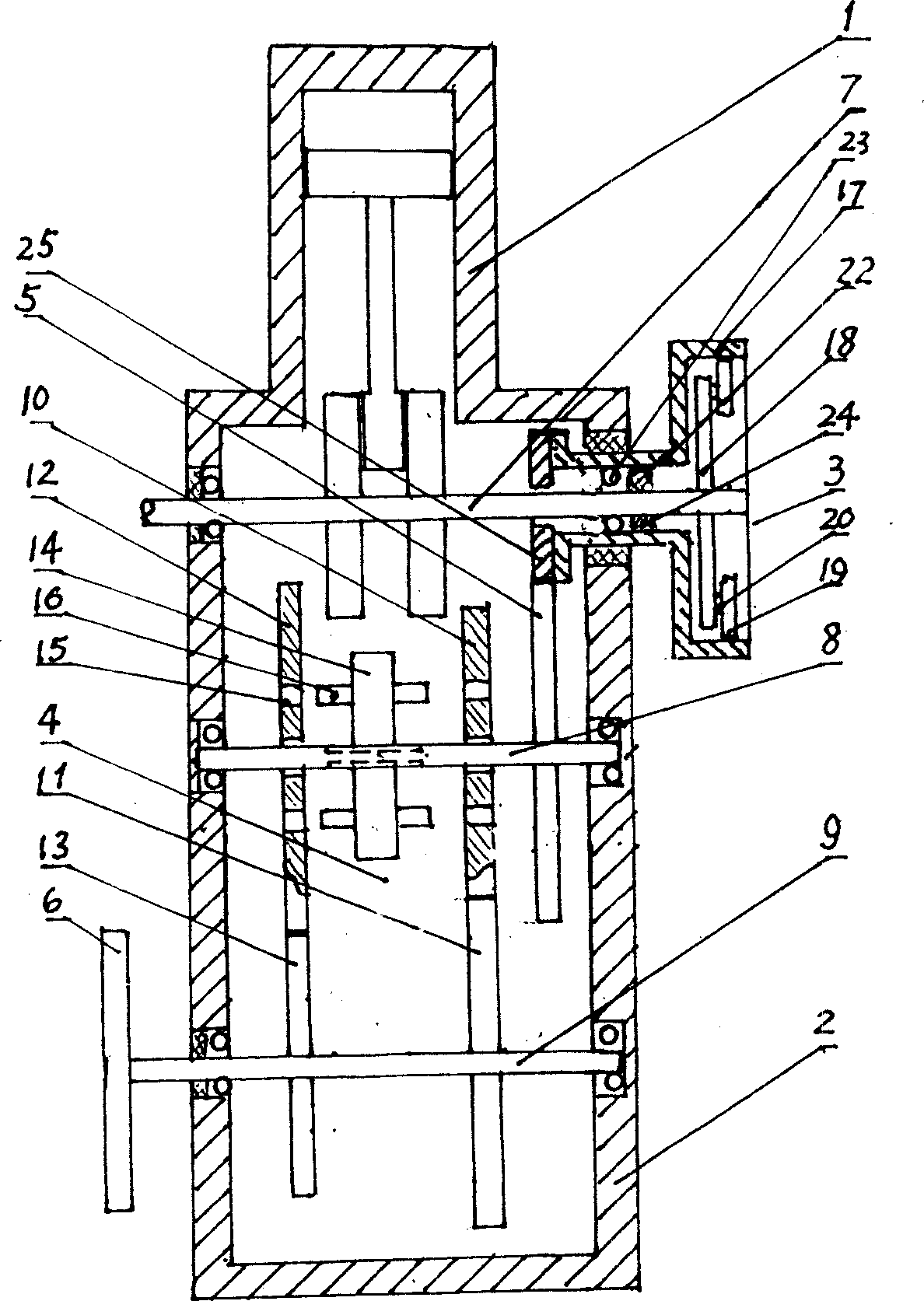

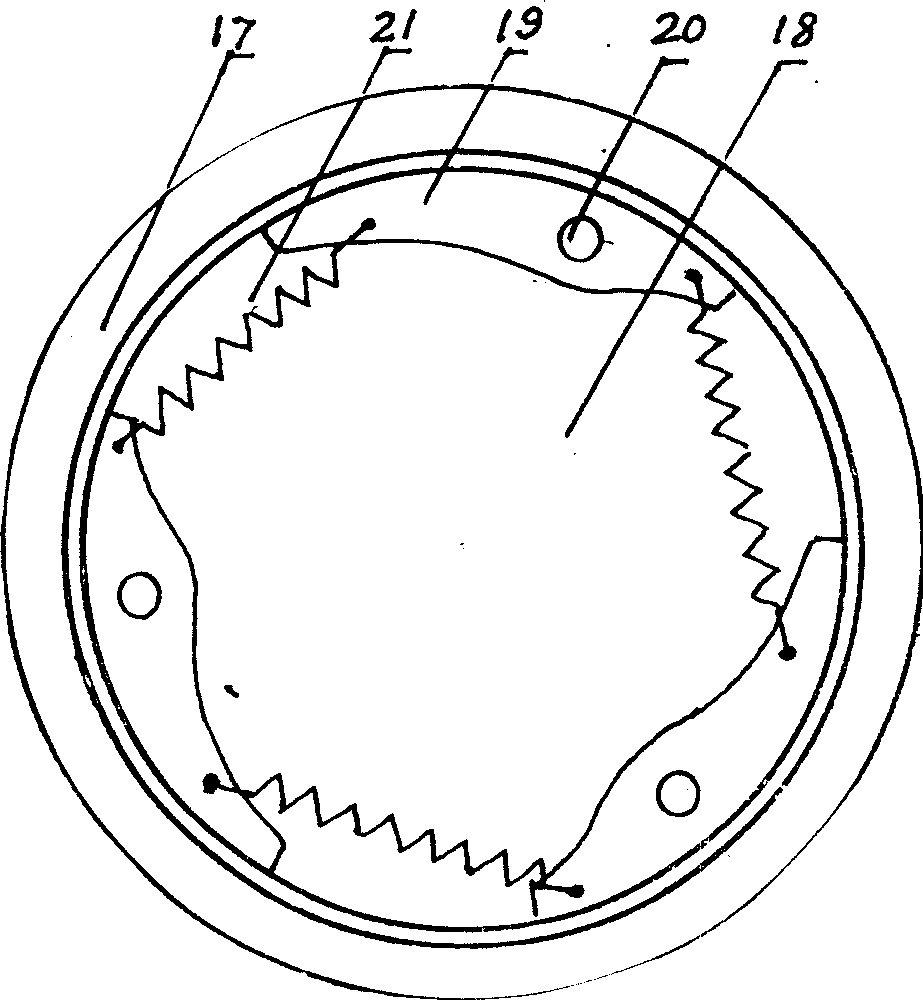

[0007] Cylinder and cylinder head combination 1 are contained on the housing 2, crankshaft 7, main shaft 8 and countershaft 9 are contained in the housing 2, crankshaft 7 two ends stretch out outside the housing 2, and the middle section of the main shaft 8 has a spline groove. The first gear main gear 10 and the second gear main gear 12 are sleeved on the main shaft 8, and a coupling hole 15 is arranged on it. The first gear slave gear 11 and the second gear slave gear 13 are installed on the subshaft 9 in the housing 2 , the first gear slave gear 11 meshes with the first gear main gear 10 , and the second gear slave gear 13 meshes with the second gear main gear 12 . The gear shifter 14 is installed on the spline groove of the main shaft 8, and its two end faces have coupling pins 16. When the gear shifter 14 slides to the right to insert the coupling pin 16 into the coupling hole 15 of the primary gear 10 of the first gear, the main shaft 8 passes through the gear shift. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com