Refrigerator

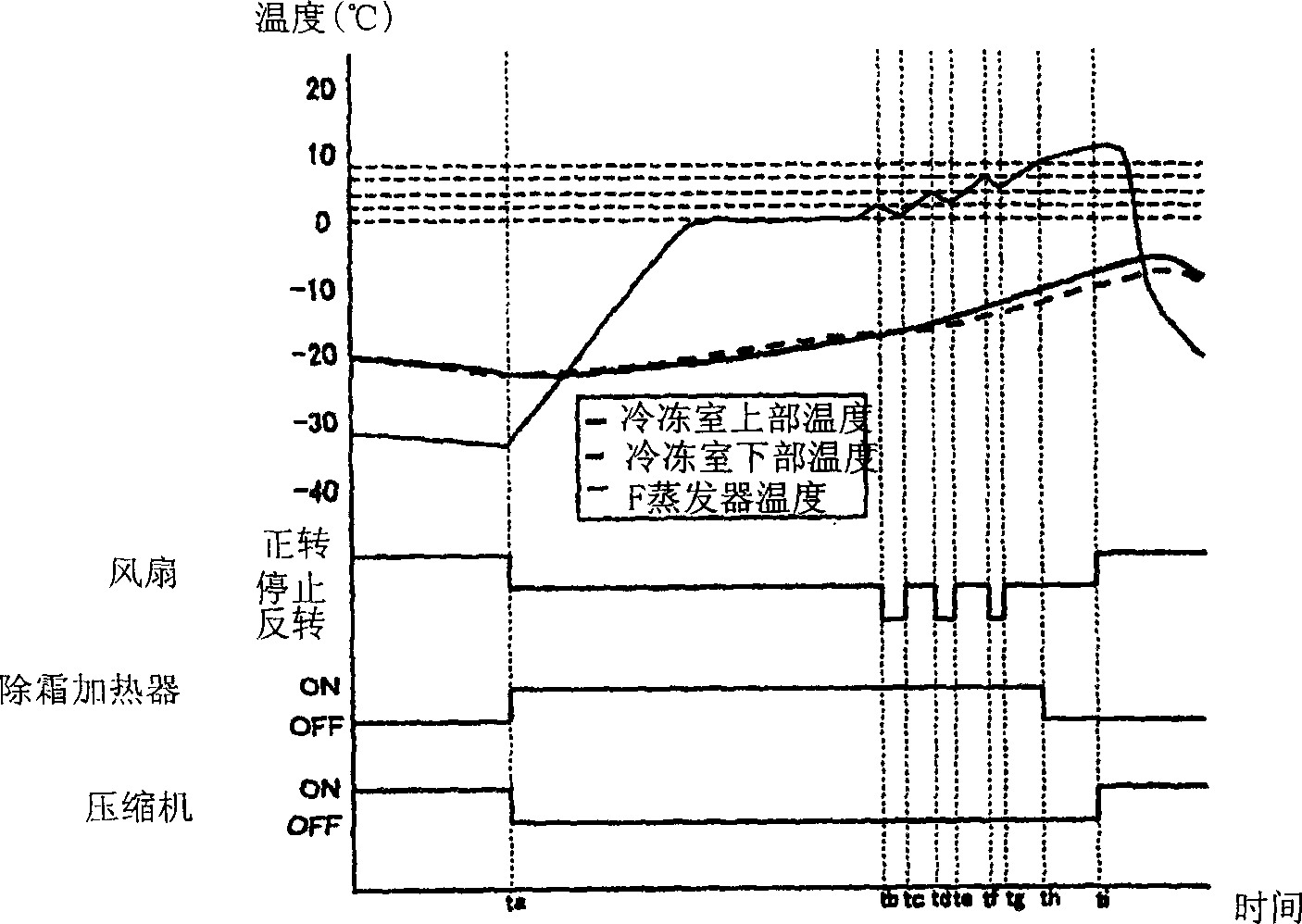

A refrigerator and evaporator technology, applied in the field of refrigerators, can solve the problems of long inversion time, long sum of rotation time, and rising average temperature of storage room, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

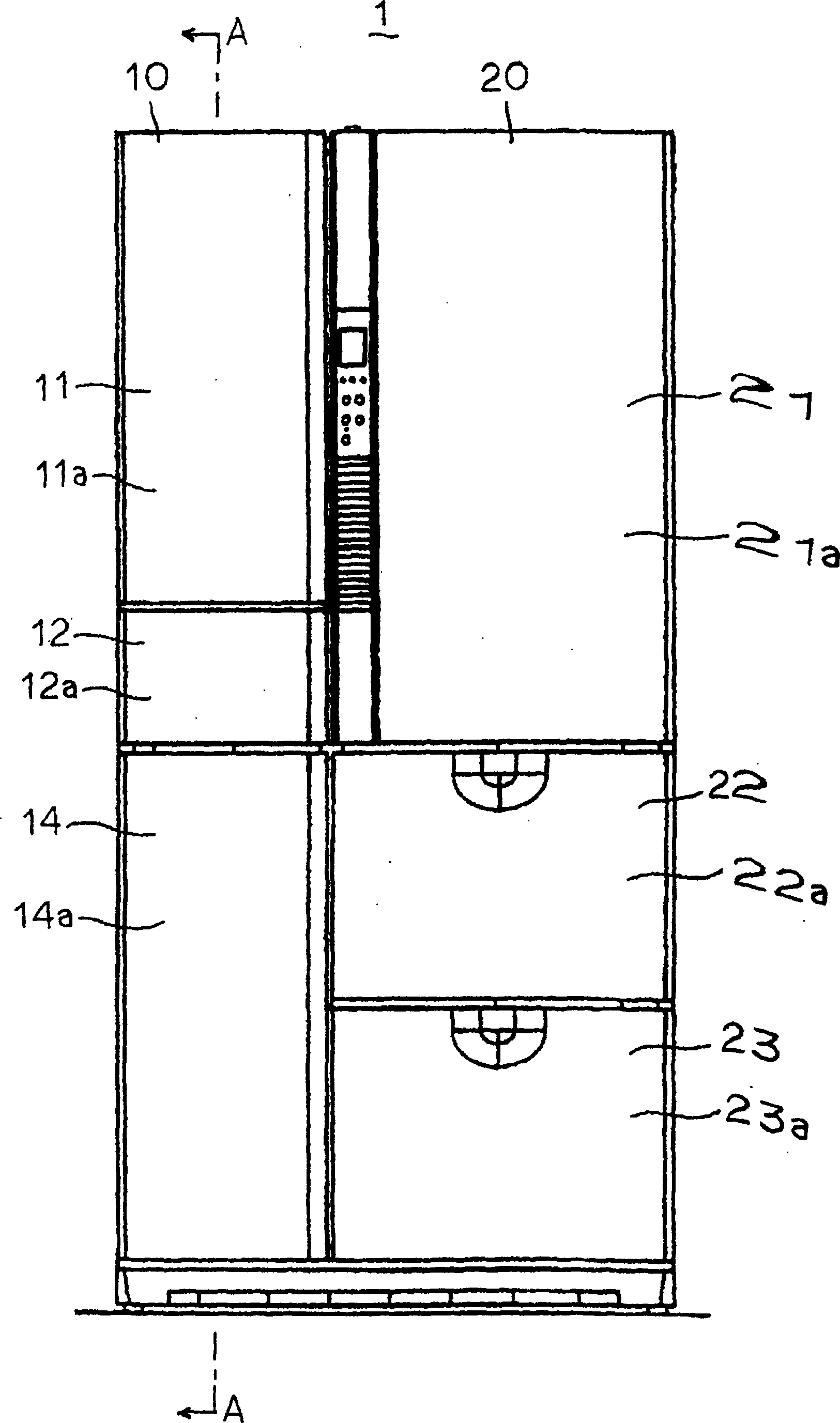

[0015] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 2 It is a front view of a refrigerator showing an embodiment of the present invention, image 3 Yes means omitted figure 2 The front view of the state of the door of the refrigerator, Figure 4 It represents the freezer, along the figure 2 A cross-sectional view of the refrigerator along the line A-A.

[0016] The refrigerator body 1 divides the freezer storage compartment 10 and the refrigerated storage compartment 20 into left and right positions, and the two storage compartments have independent flow of cold air. A machine room 31 is provided at the bottom of the back of the refrigerator body 1, and a compressor 33, a heat dissipation fan (not shown), a condenser 34, and the like are arranged.

[0017] In the freezer storage compartment 10, a first freezer compartment 11, an ice-making compartment 12 with an automatic ice maker 13, and a second freezer compartm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com