Method for extracting theaflavin

An extraction method and theaflavin technology, applied in the direction of organic chemistry, can solve the problem that chemical reagents cannot be recycled, and achieve the effects of low cost, high product yield and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described in detail below.

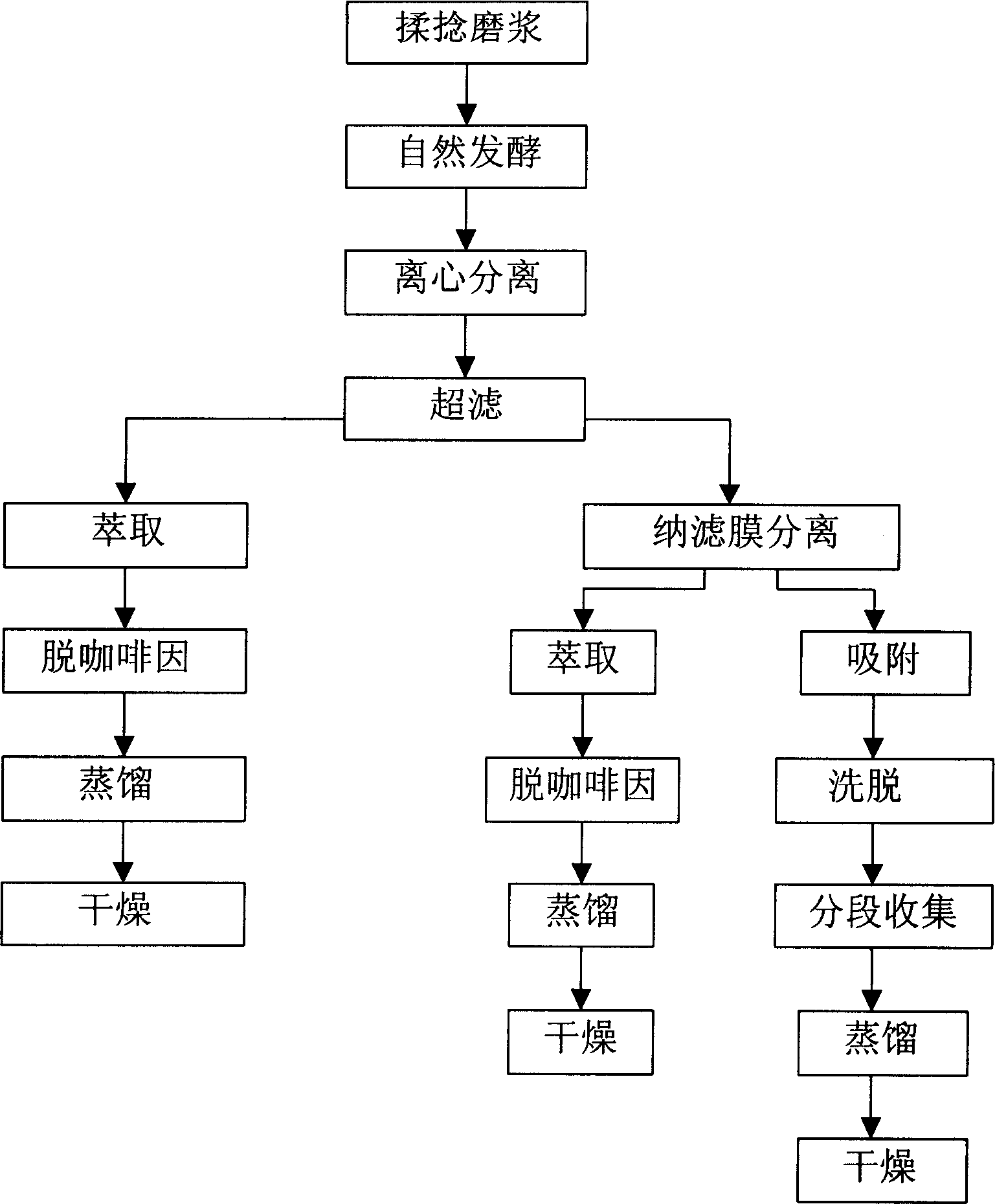

[0008] The extraction method of theaflavins designed in the present invention includes a fermentation process and a preparation process.

[0009] 1) During the fermentation process, the fresh tea leaves are kneaded and then refined with water, the ratio of material to water is 1:1-20, and then put into the fermentation tank, and the temperature is 30-40°C, and the pH value is 5-6. Air or oxygen, stirring, and natural fermentation for 20-60 minutes to obtain theaflavin solution. In order to improve the utilization rate of fresh tea leaves, water extract of dry tea leaves or tea polyphenols can be added for mixed fermentation, and then the theaflavin solution The slag is removed by centrifugation, the tea slag is fermented and dried by microorganisms to obtain an organic fertilizer, and the centrifugal liquid is subjected to ultrafiltration through a ceramic membrane to obtain a filtrate; the membrane pore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com