Method and apparatus for treating urban sewage by means of flue gas desulfurization of power plant and fly ash

A technology of urban sewage and fly ash, applied in chemical instruments and methods, separation methods, biological water/sewage treatment, etc., can solve problems such as difficult operation, difficult sewage treatment costs, unblocked charging channels, etc., and achieve a large environment and social benefits, protection of water environment and atmospheric environment, improvement of treatment compliance rate and recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

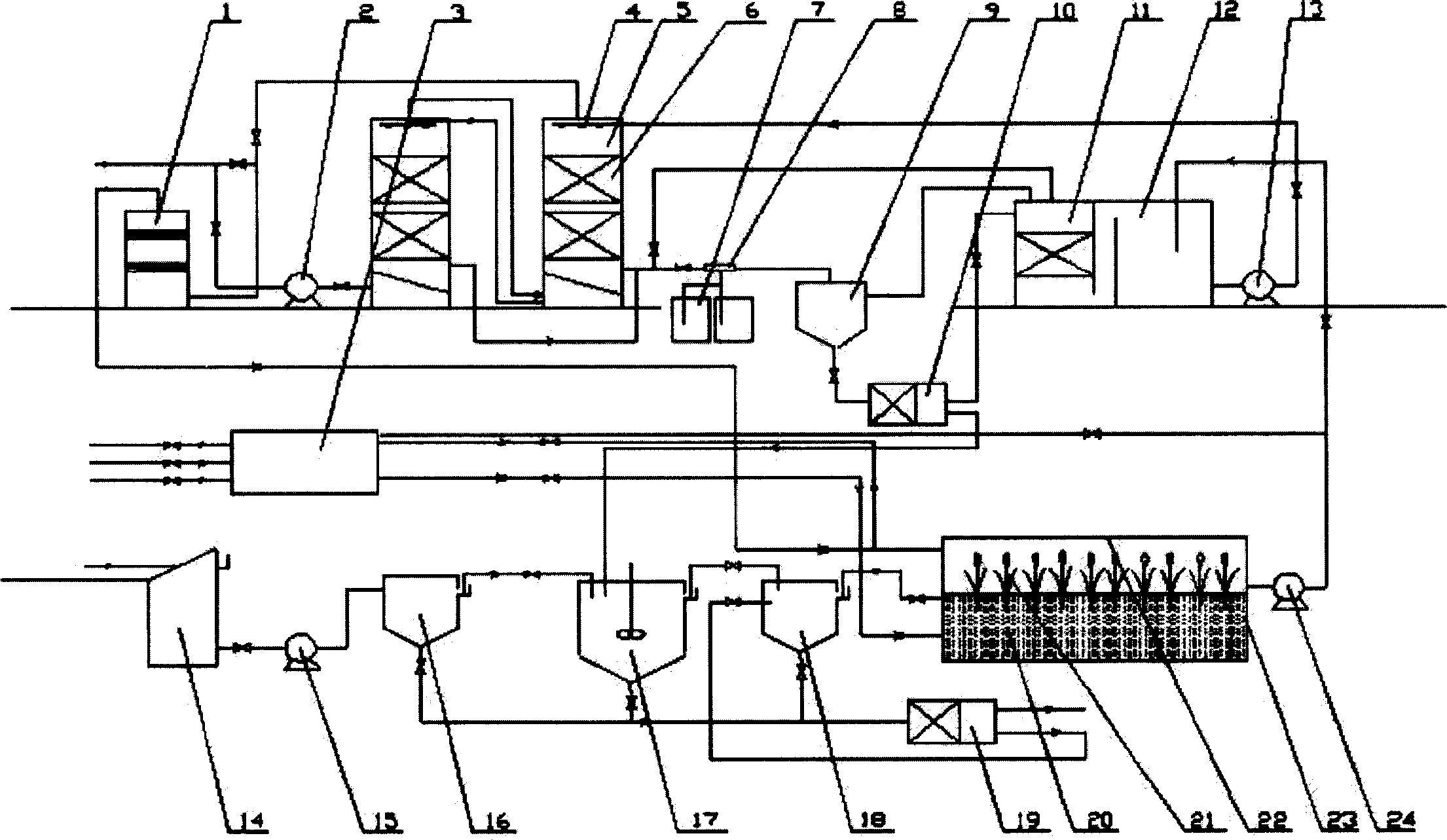

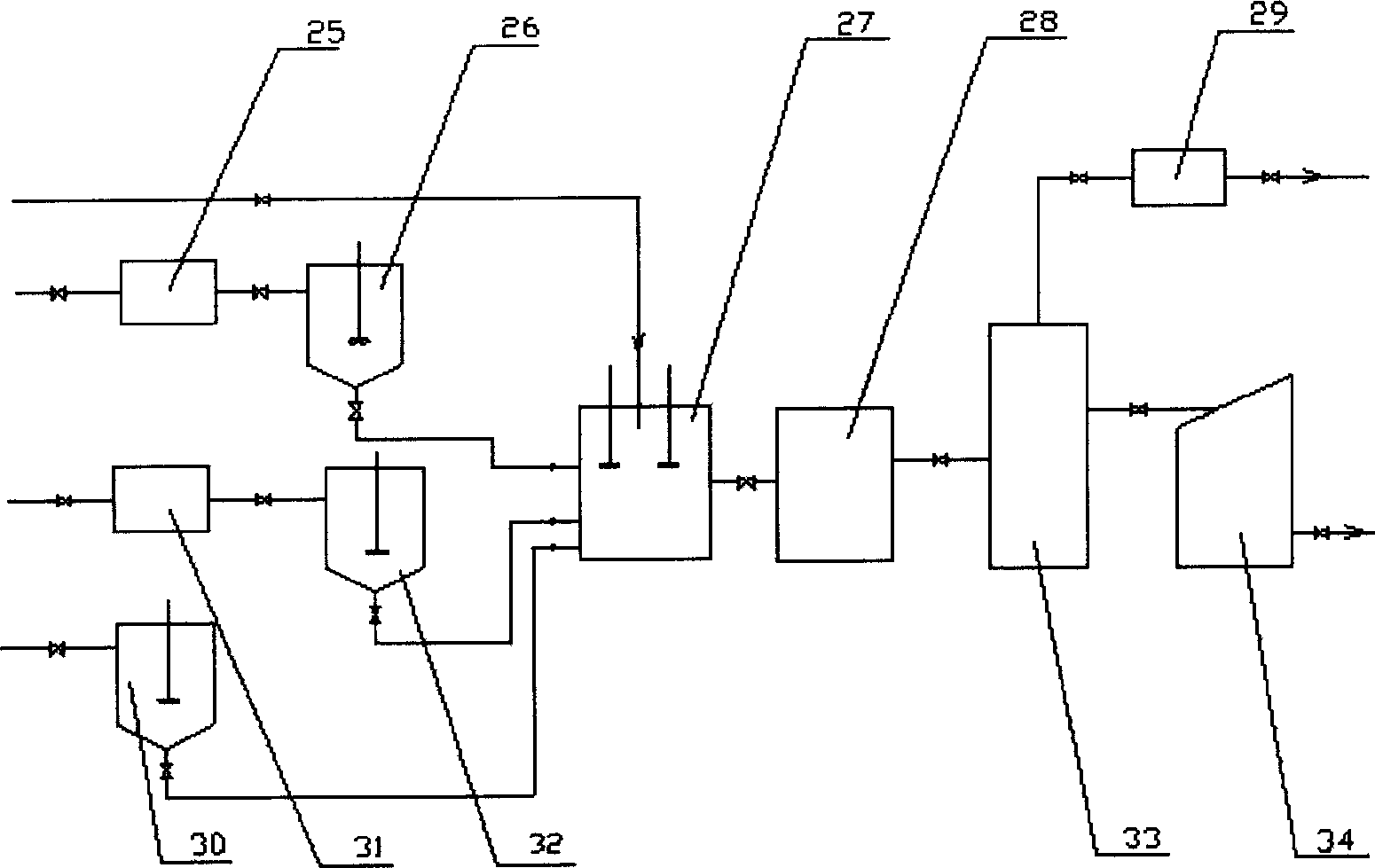

[0030] Design basis: daily water treatment volume: 100,000 tons; raw water COD concentration: 400mg / l; treated COD concentration: 50mg / l flue gas sulfur dioxide concentration: 500mg / standard cubic meter; flue gas sulfur dioxide concentration after desulfurization: 50mg / standard cubic meter ;Temperature before flue gas desulfurization: 70-100°C; Temperature after flue gas desulfurization: 30-40°C; Ecological treatment unit temperature: Summer: 30-35°C; Winter: 25-30°C;

[0031] Process parameter calculation:

[0032] 1. Sedimentation tank 16: residence time: 4 hours, 17,000 cubic meters, built under the ecological treatment unit.

[0033] 2. Coagulation tank 17: Dosing coagulant: 200mg / l; dosage: 20 tons / day; effective iron equivalent to 4 tons / day; coagulation reactor: residence time: 0.2 hours; 800 cubic meters; secondary settling Pool 18: 1.5 hour residence time inclined plate, volume: 6250 m3, built under the ecological treatment unit.

[0034] 3. Ecological treatment uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com