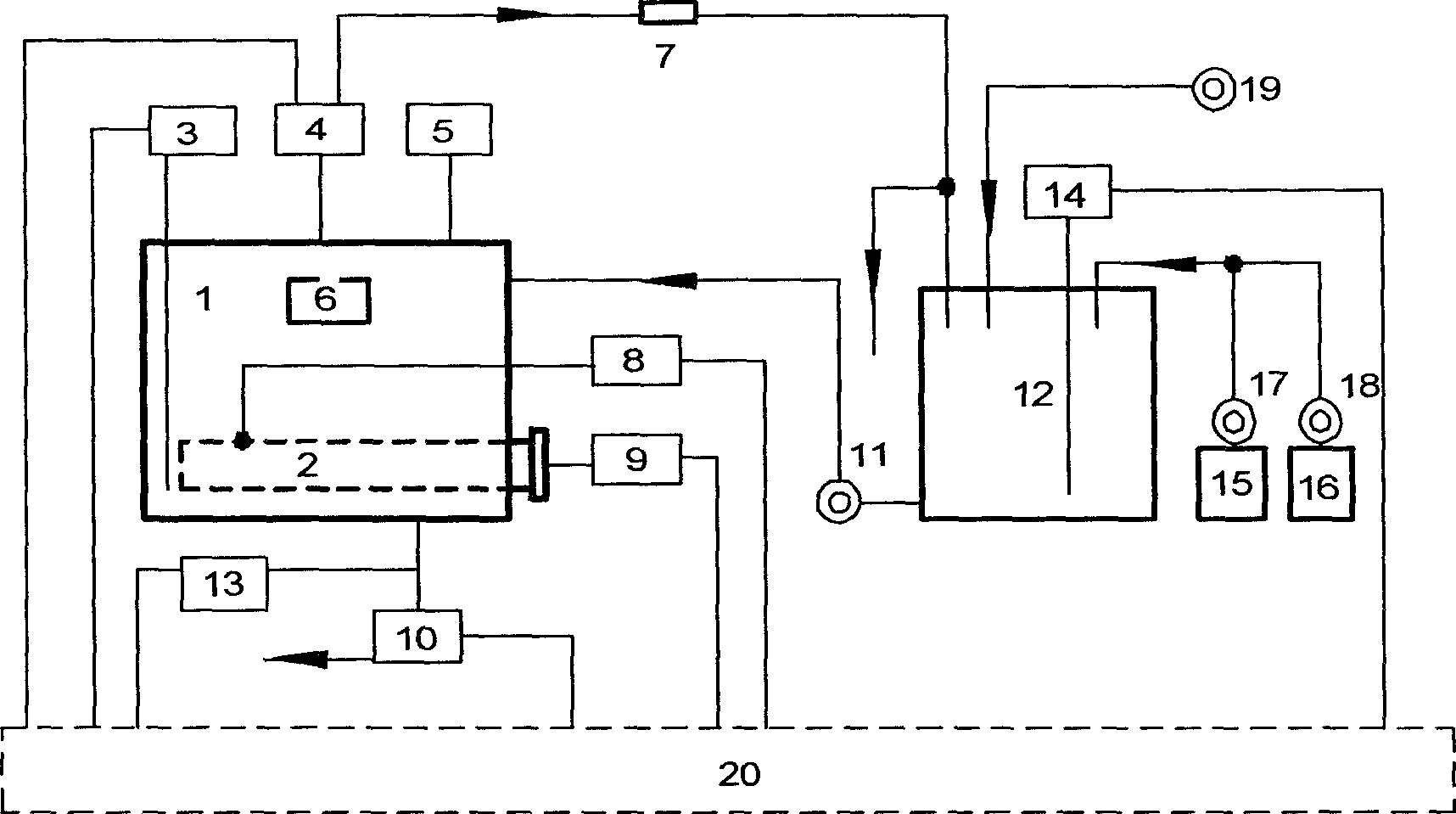

Method for testing scale and corrosion inhibition performance of reagent and apparatus for boiler water treatment

A technology for water treatment equipment and treatment chemicals, which is used in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problem of lack of testing methods and means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The organic copolymer corrosion and scale inhibitor ethylenediaminetetramethylenephosphonic acid was tested. The pressure is 2.0±0.01Mpa, the steam temperature is 213°C, the evaporation capacity is 15±0.3L / h, and the heating power is constant at 2.9±0.03Kw. Preparation of water quality 1 2 C a 2 + + 1 2 Mg 2 + = 6 mmol , HCO 3 - 180mg / l, SO 4 2- 50mg / l, Cl - 105 mg / l, pH 9.0. The experimental time Δt=144 / hour. Under the above conditions, the scale inhibition rate of the agent is 88.2%, the corrosion inhibition rate is 92.4%, and the corrosion rate of the pipeline is 0.050mm / a, which is consistent with the effect of the agent on the running boiler.

Embodiment 2

[0027] Test the performance of 3 / 8″ through-type water treatment equipment with built-in composite metal materials. The pressure is 1.0±0.01Mpa, the steam temperature is 183°C, the evaporation rate is 15±0.3L / h, and the heating power is 2.9±O. 03Kw. Natural raw water quality Ca 2+ 72.1mg / l, Mg 2+ 33.9mg / l, alkalinity 3.59mmol / l, Cl - 119.9 mg / l, pH 7.56. Experimental time Δt = 144 hours. Under the above conditions, the scale inhibition rate of the agent is 66.7%, the corrosion inhibition rate is 44.7%; the corrosion rate of the pipeline is 0.085mm / a, which is consistent with the effect of the equipment on the running boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com