Device and method for forming a stack of sheets on a delivery surface

A sheet and equipment technology, applied in the field of sheet lamination, can solve problems such as difficulty in moving, inability to flatly abut, sheet wrinkling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

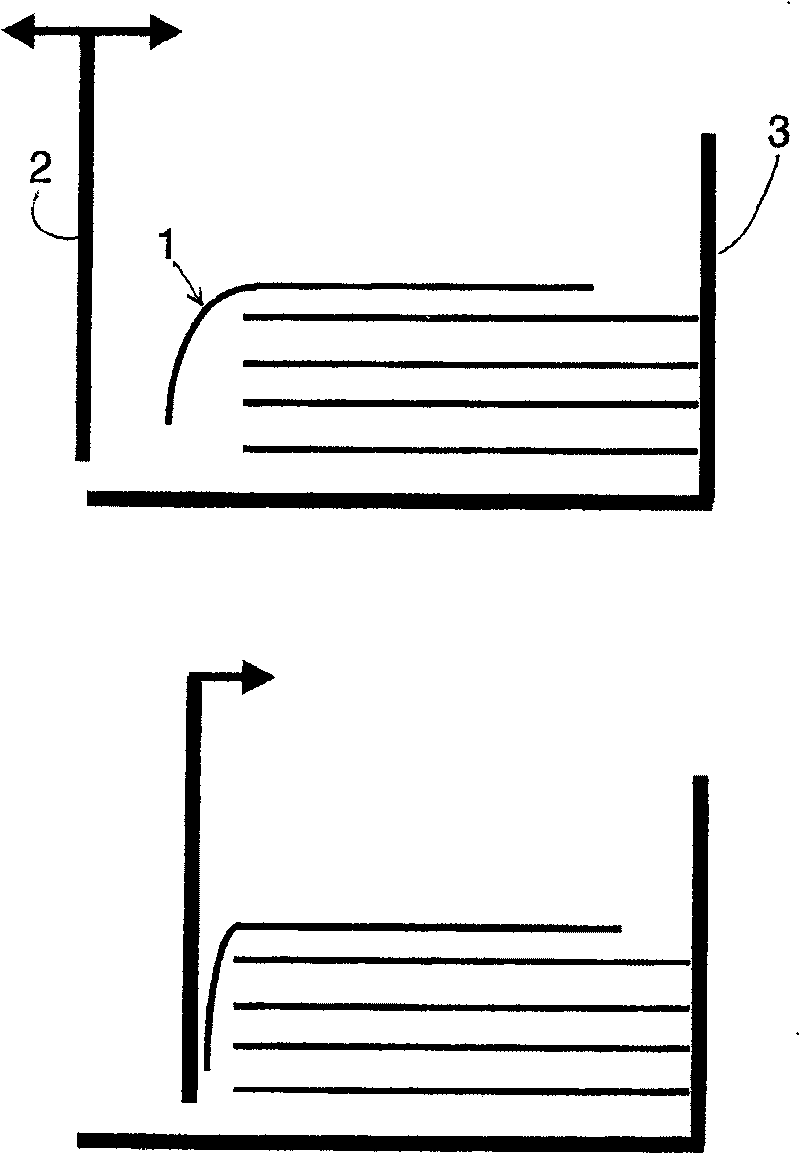

[0023] figure 1 Problems that may arise when stretching a flake curled up during the collection process in order to enable possible subsequent processing or removal from the stack are shown. As a result of stretching or nudging the sheets placed on top of the stack, it is possible for one or more sheets to rest incorrectly against the baffle and, after multiple impacts, may even be damaged changing their mass and / or fail to bind together with other sheets in the stack that have curled, for example, from bending of the paper path in the machine, from moisture, or from temperature changes. This phenomenon is undesirable. The problem is especially pronounced in systems with large volumes, high output speeds, and multiple substrates. Post-processing stations must always be able to work faster and handle an ever-increasing variety of materials and, in practice, must be able to switch from very thin and brittle paper to thick and rigid paper.

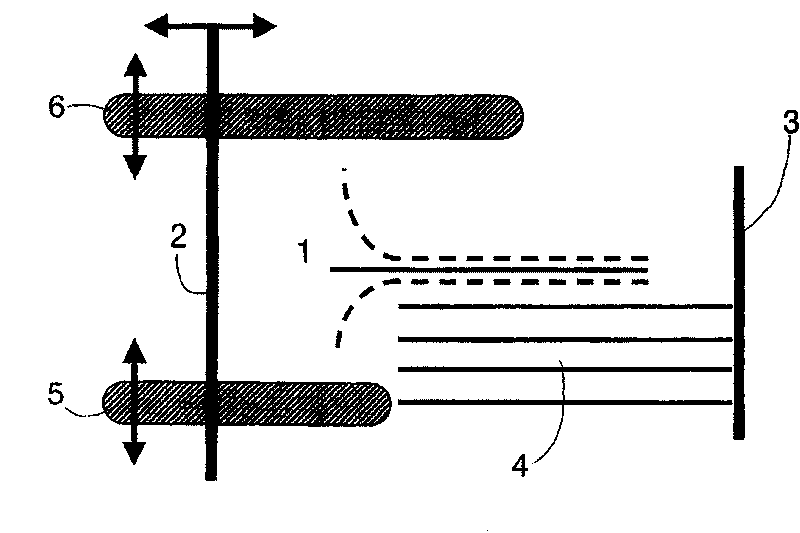

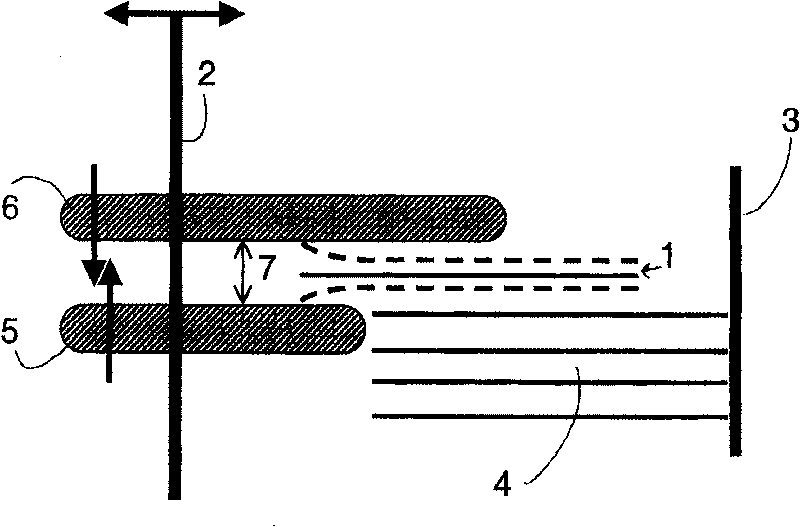

[0024] figure 2 is a side view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com