Engine rack structure

An engine bracket and engine technology, which is applied to the substructure, power plant, non-rotational vibration suppression, etc., can solve problems such as cost and weight increase, and achieve the effects of improving workability, suppressing weight or cost increase, and improving positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

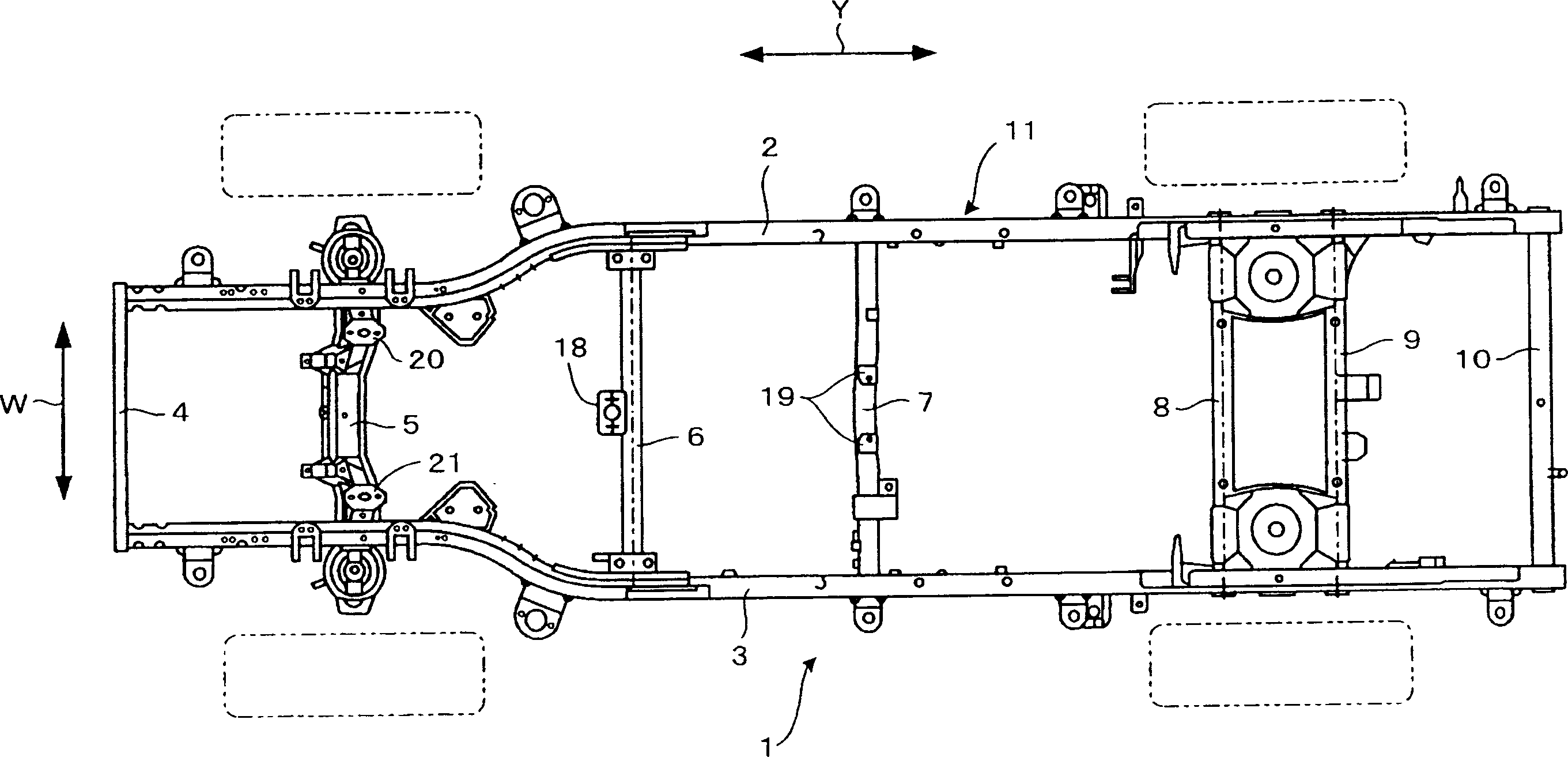

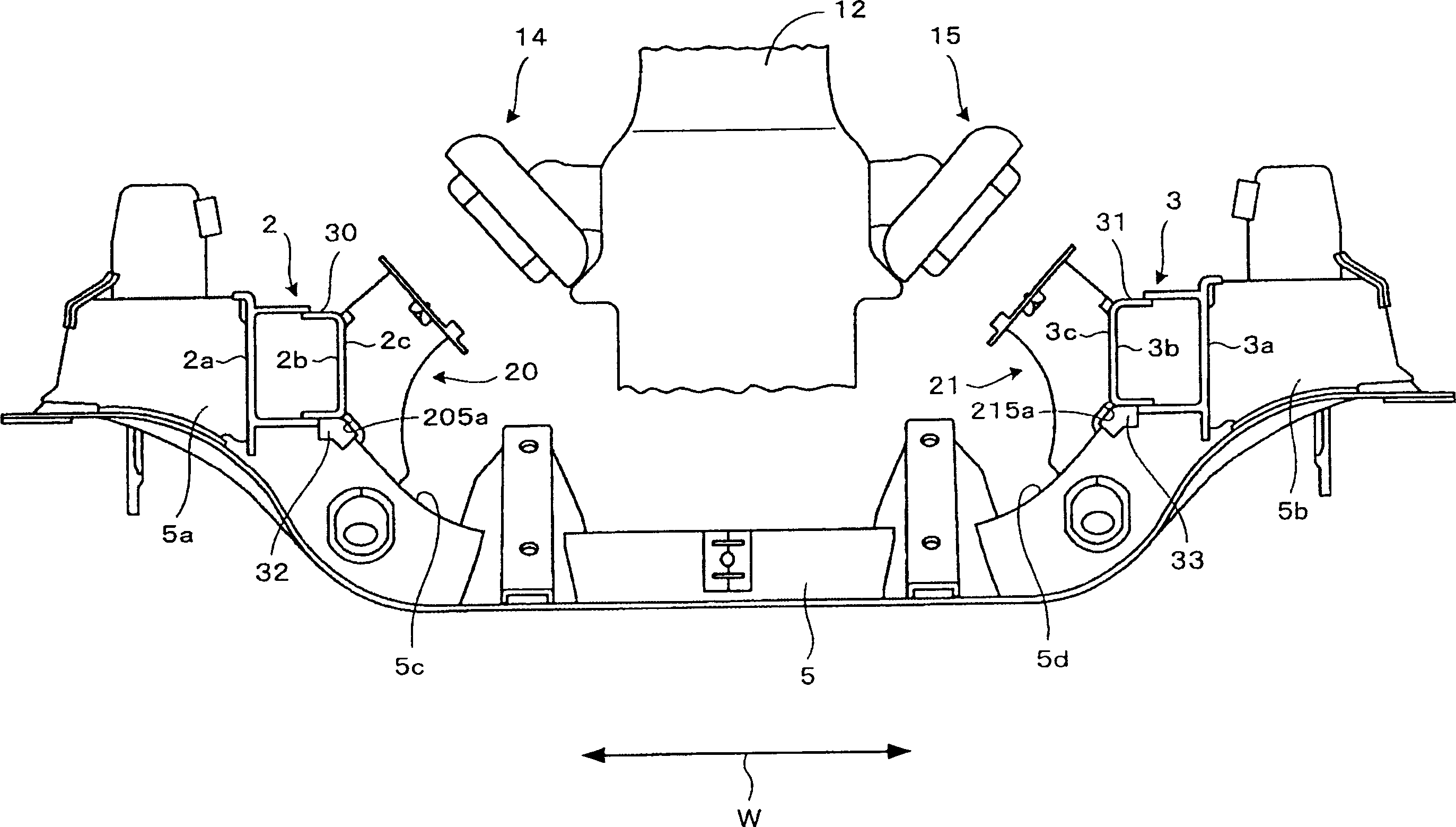

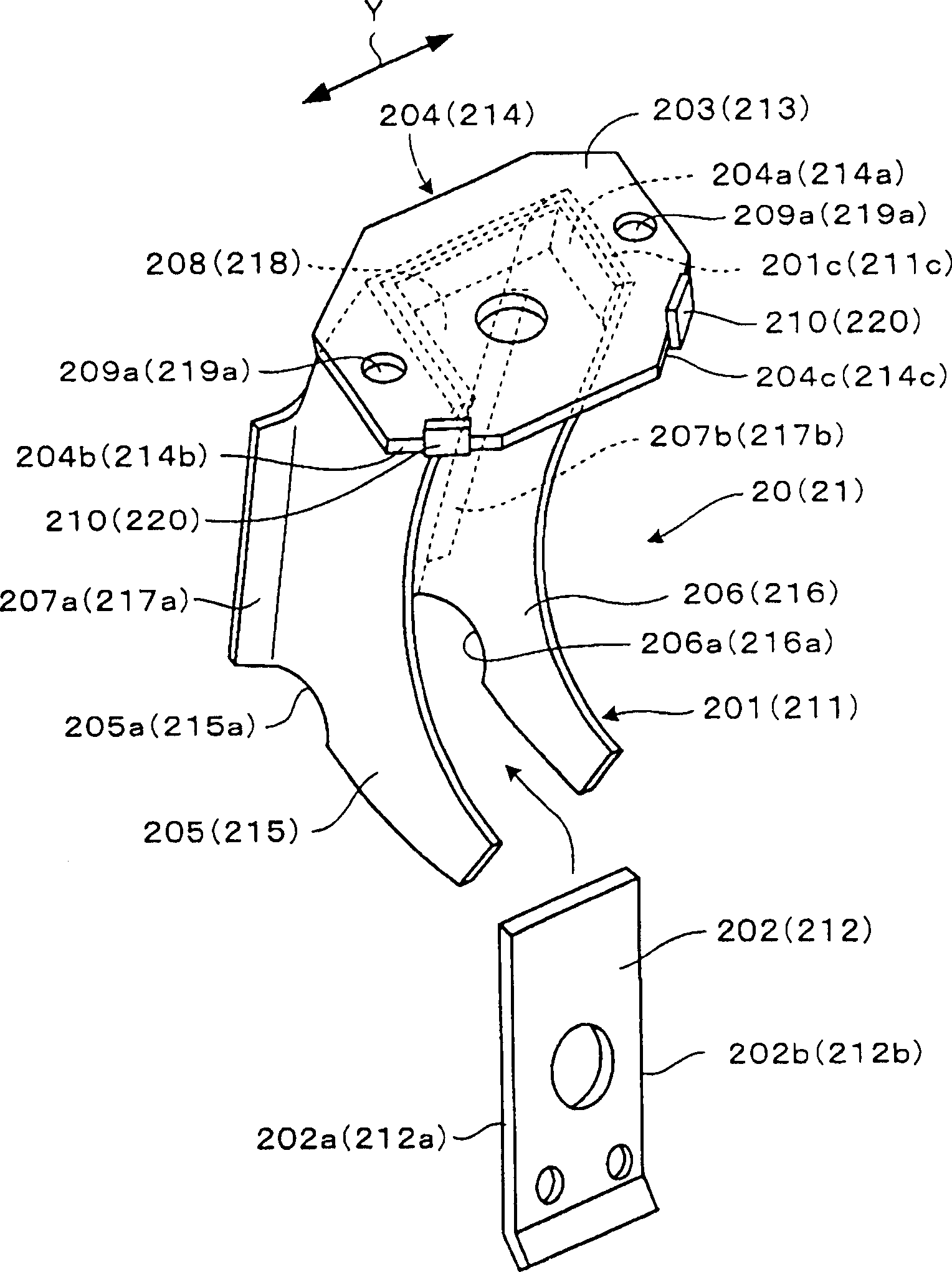

[0018] Embodiments according to the present invention will be described with reference to the drawings. Such as figure 1 As shown, in the vehicle width direction indicated by symbol W, a pair of side members 2 and 3 extending in the front-rear direction of the vehicle 1 indicated by arrow Y are arranged. The vehicle frame 11 is formed by fixing both end sides of the plurality of beams 4 to 10 to the side beams 2 and 3 by welding, respectively. Of these beams, the beam 4 forms the front beam and the beam 10 forms the rear beam. Such as figure 2 As shown, both ends 5a, 5b of the cross member 5 located on the vehicle rear side than the cross member 4 protrude from the side members 2, 3 in the vehicle width direction. A strut portion (not shown) of the front suspension is attached to the protruding both ends 5a, 5b, and functions as a suspension beam. Beams 8 and 9 positioned closer to the front of the vehicle than cross member 10 function as rear suspension beams that suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com