Leading edge feeder

A front edge, resting technology, applied in the directions of transportation and packaging, object separation, pile separation, etc., can solve the problems of complex, expensive, and complex guiding structure beams, and achieve the effect of precise and simple processing positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

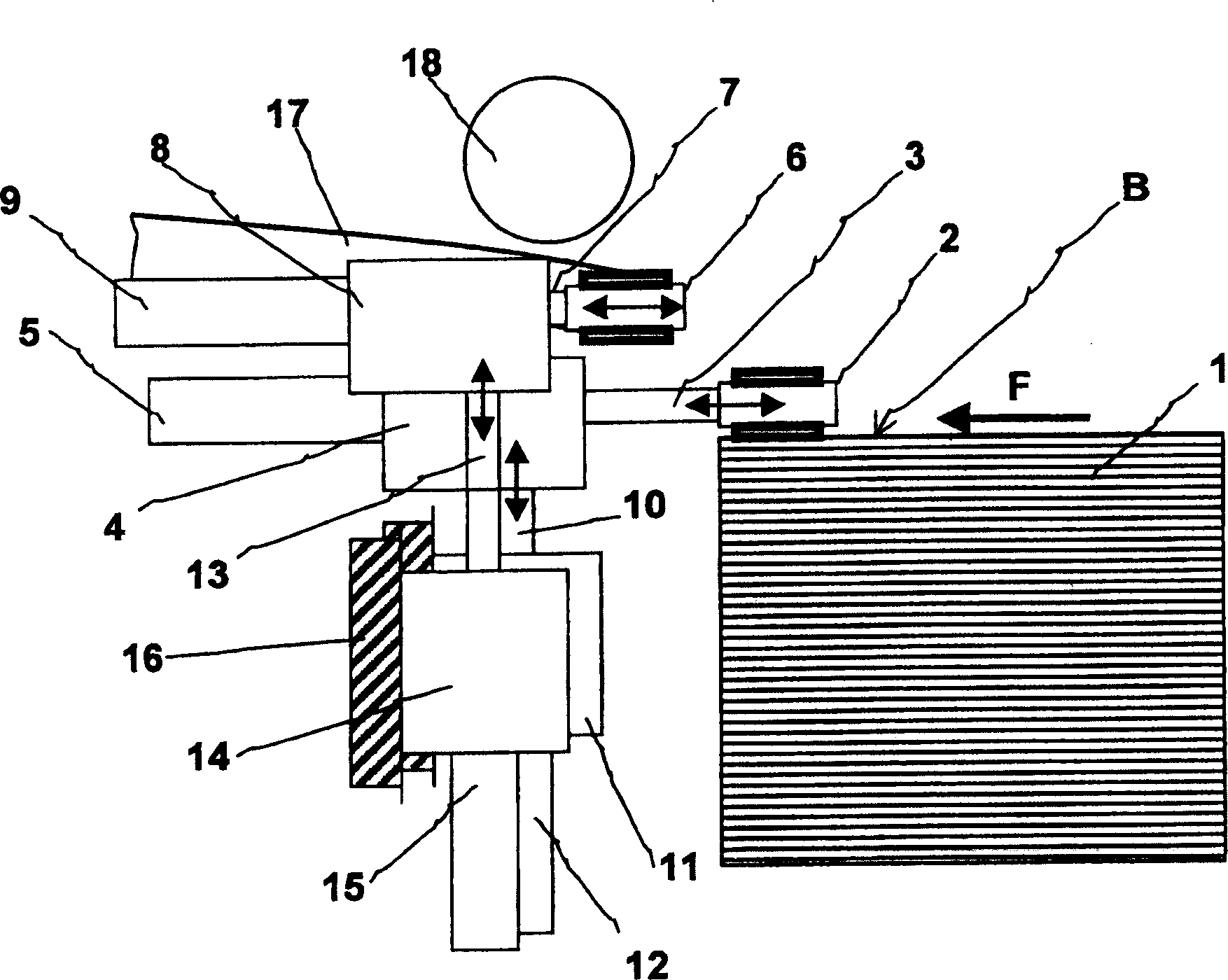

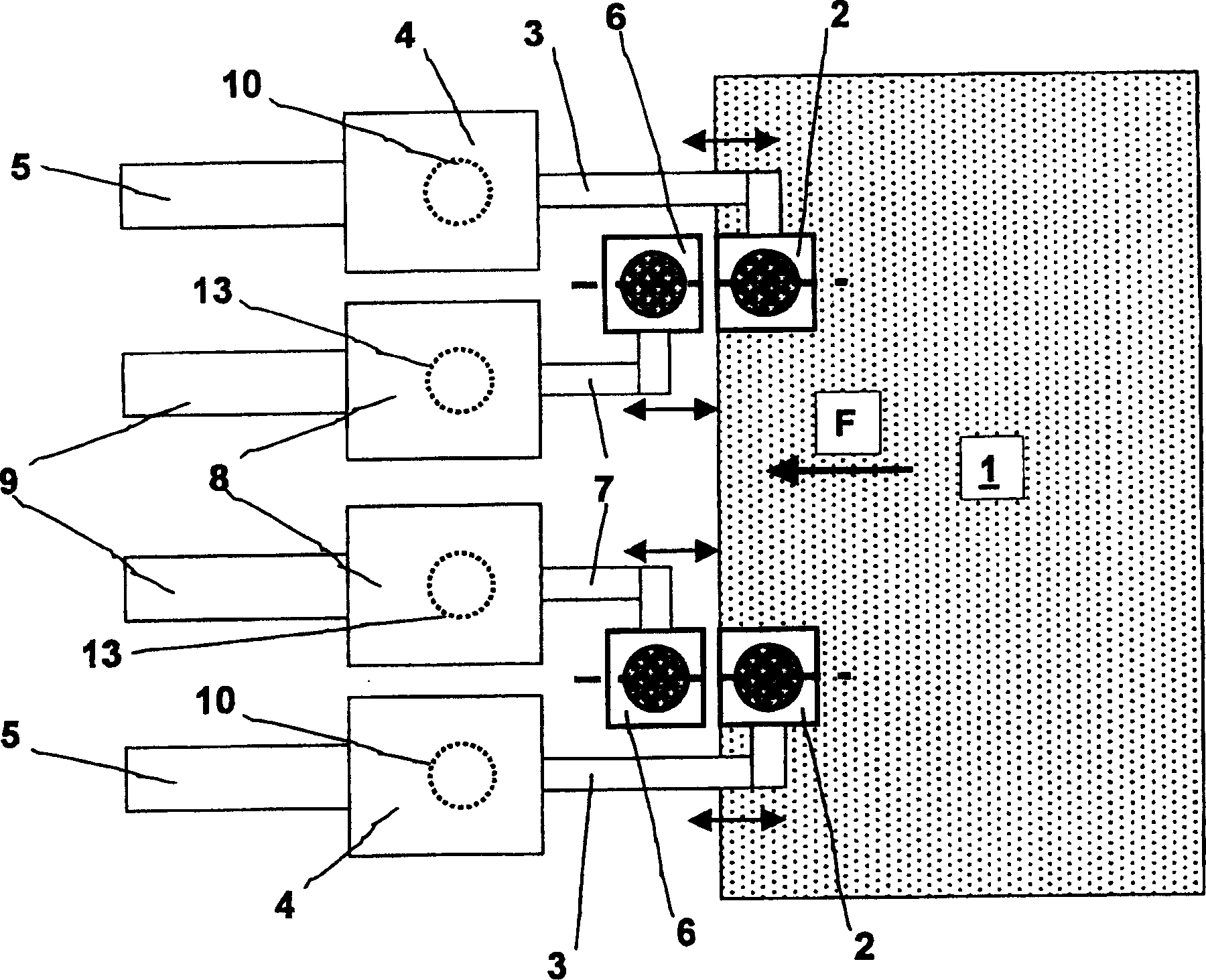

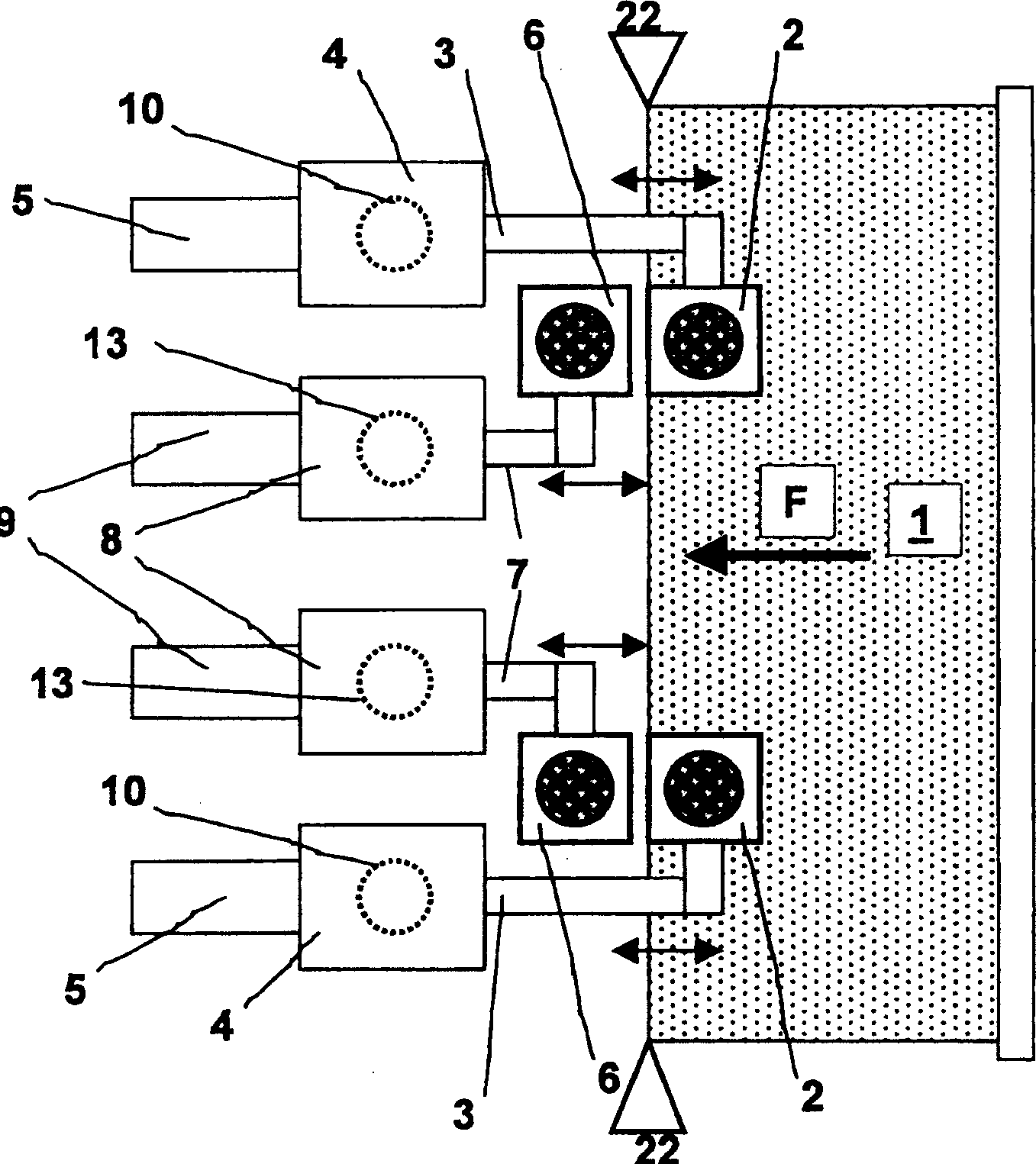

[0018] figure 1 A sheet separating device in the form of a front edge separating device is shown. This front edge separating device is arranged corresponding to the front edge of a stack 1 in the transport direction F of the sheets B to be separated into individual sheets. The separated sheets B are transported in a transport direction F to a machine for processing the sheets B, not shown here. For this purpose, the sheet B is usually conveyed via a transport table 17, for example a suction belt table. In order to reliably transfer the sheet B from the front edge separating device to the transport table 17, a so-called timing roller 18 can be provided here. By means of the beat rollers 18, the conveyed individual sheets are fixed on the transport table 17 in the beat of the arrival of the sheets for further transport.

[0019] The front edge separating device of the present invention is provided with a plurality of suction nozzle driving devices. On the paper stack 1 , a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com