Distributed arc electroerosion

一种电蚀、电弧的技术,应用在电弧焊设备、电路、电极制造等方向,能够解决增加叶盘成本、大时间和费用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

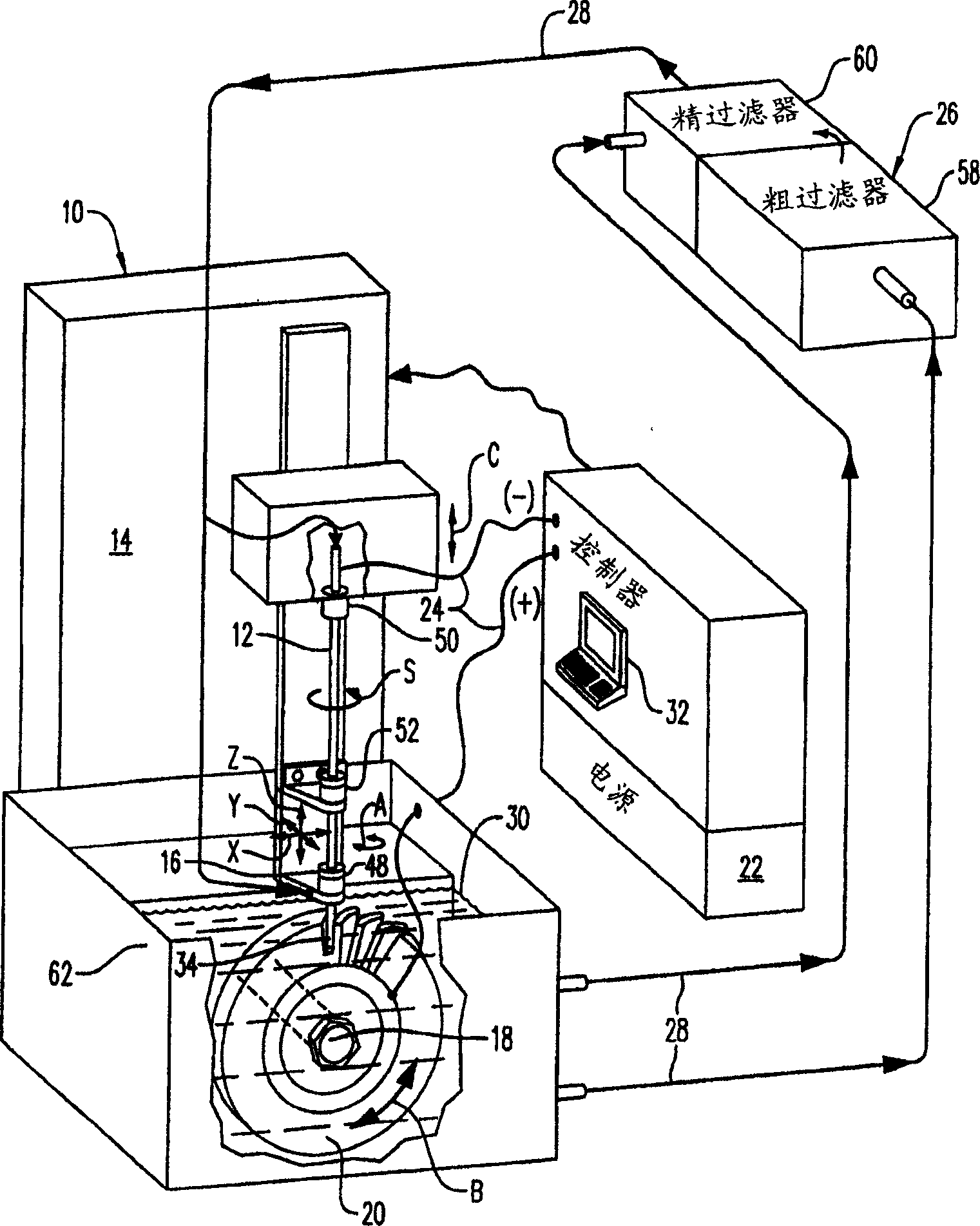

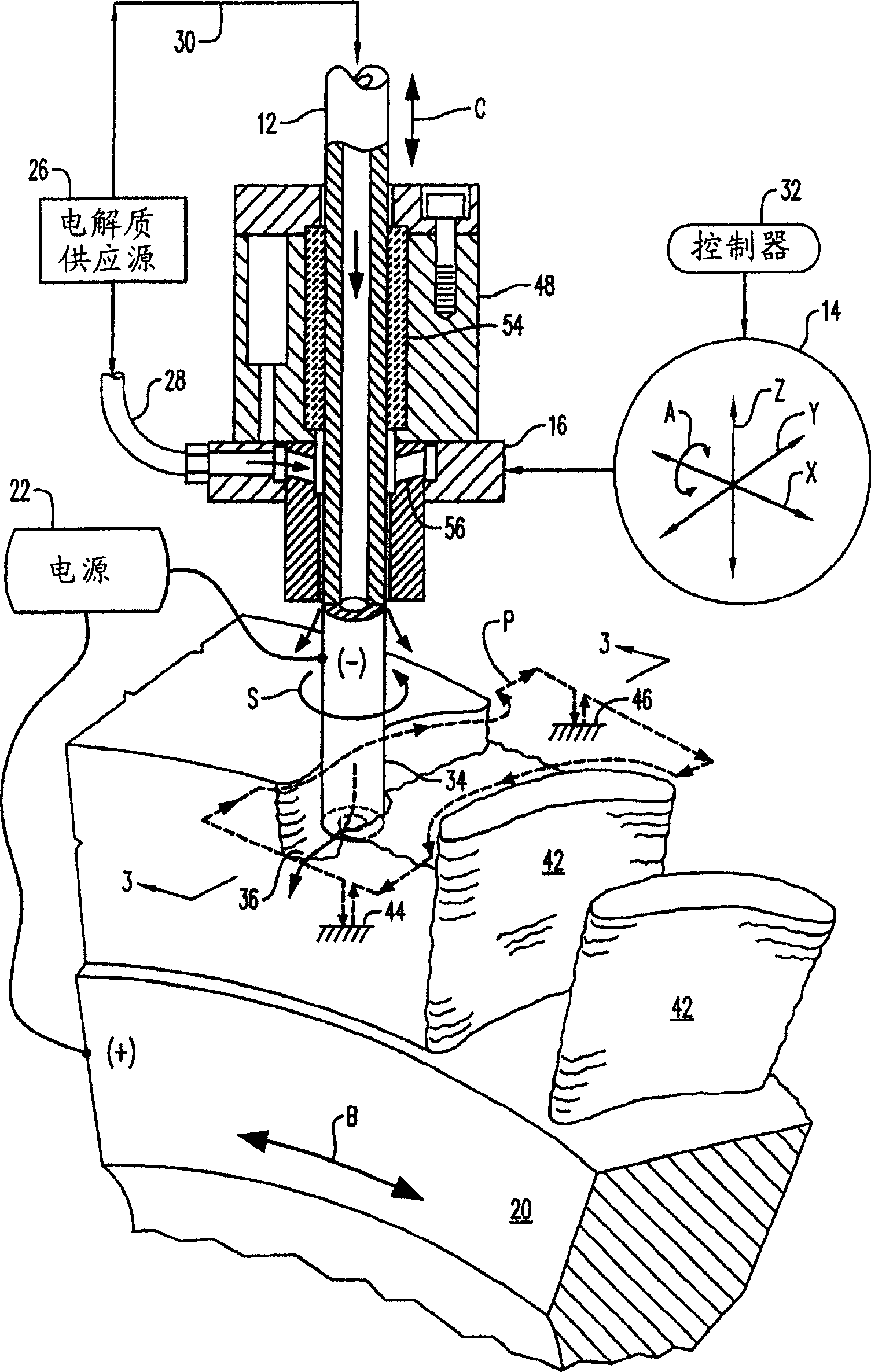

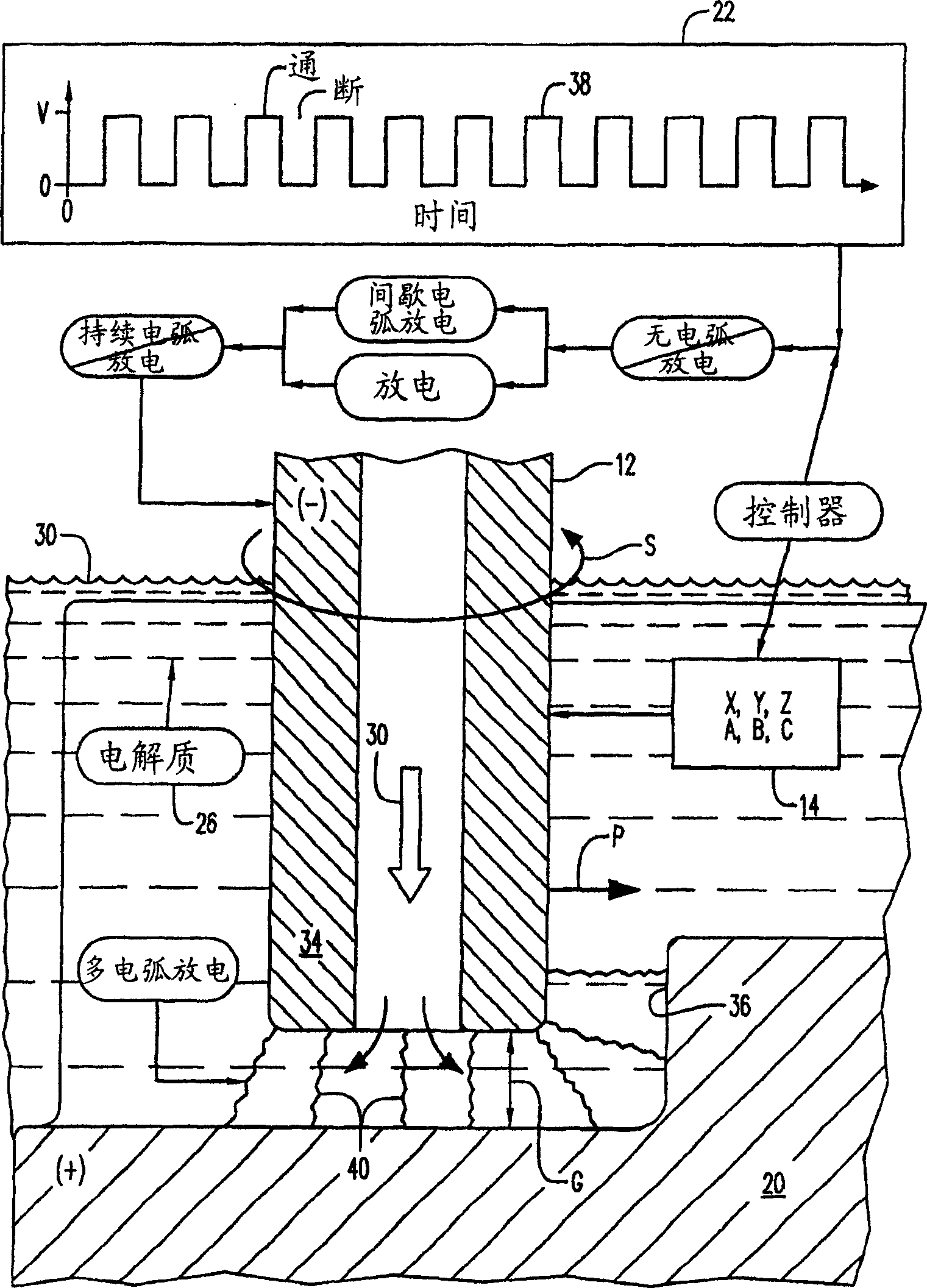

[0029] figure 1 An electroerosion machine or apparatus 10 comprising a tubular cutting tool or electrode 12 is schematically shown. The apparatus includes a multi-axis numerically controlled (NC) machine 14 including a tool holder 16 that supports the electrode for rotation or spinning S in operation and has multiple axes of movement. The machine also comprises a suitable support table in the typical form of a rotating mandrel 18 supporting the workpiece 20 and preferably having an additional axis of movement.

[0030] Means in the form of a conventional direct current (DC) power source 22 are provided to transmit electrical energy through the electrode 12 and workpiece 20 in operation. The power supply includes suitable electrical leads 24 respectively connected to the electrode 12, which in one embodiment acts as the cathode (-), and to the workpiece, which acts as the anode (+). In other alternative embodiments, the polarity may be reversed to anodic electrodes and cathod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com