Assembly parts of nut washer

A technology of assemblies and gaskets, applied in the direction of nuts, threaded fasteners, screws, etc., can solve problems such as loosening, mutual sliding, and no anti-theft function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

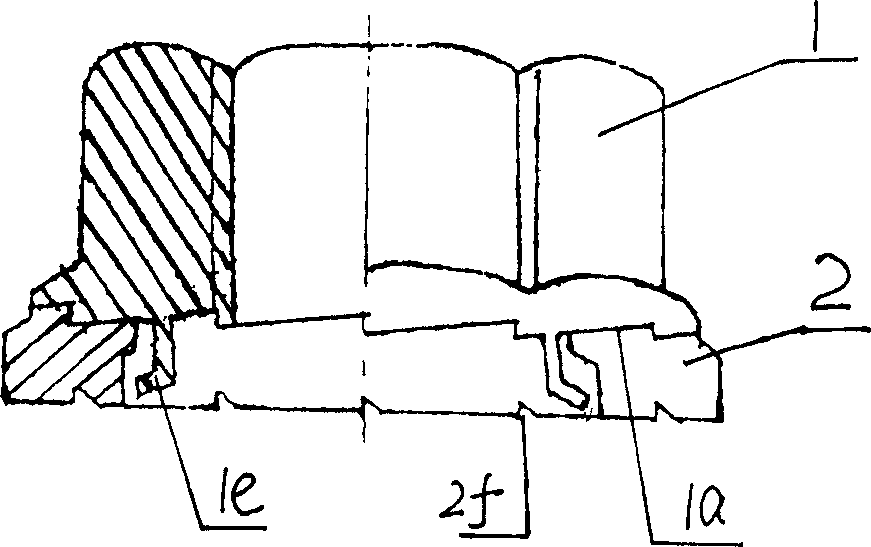

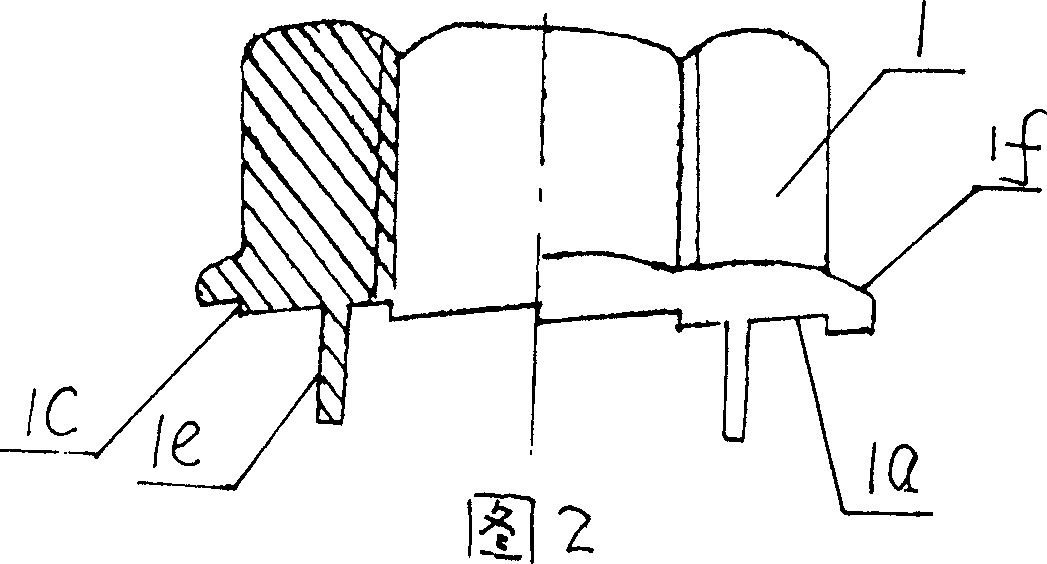

[0020] Embodiment 1 is nut 1 among Fig. 2 and Figure 5 The combination of spacers 2 in the figure 1 A nut-washer assembly in is also the first embodiment of the present invention. The utility model is an anti-loosening and anti-theft combination nut for tire rims.

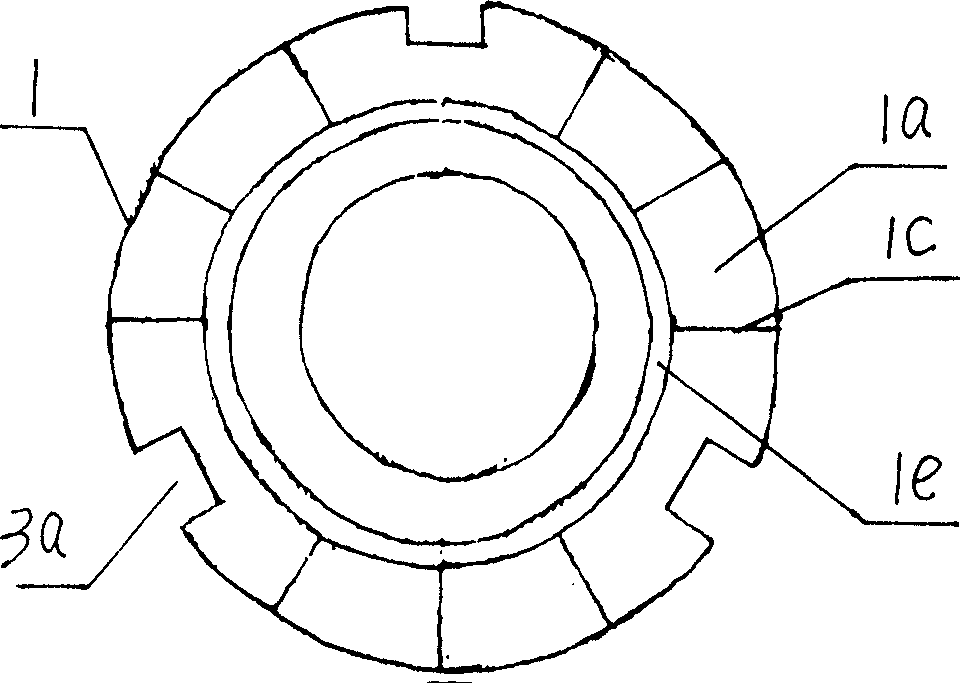

[0021] The structure of a nut washer assembly of the present invention is as follows: figure 1 ,figure 2, image 3 ,Figure 4, Figure 5 , Image 6 , Figure 7 As shown: it is composed of a nut 1 and a gasket 2, the edges of the nut 1 and the gasket 2 are respectively provided with several notches 3a, 3b, one end of the nut 1 is hexagonal, and the other end of the nut 1 has a flange surface 1f, a cylindrical ring 1e is integrally formed under the flange surface 1f, and a wedge-shaped inclined surface 1a arranged at an equal angle, with one side high and the other side low as an inclined push surface, is arranged between the cylindrical ring 1e and the edge of the nut. At the same time, each wedge-shaped incli...

Embodiment 2

[0023] Embodiment 2 is nut 1 among Fig. 2 and Figure 8 The gasket 2' in the combination constitutes Figure 11 A nut-washer assembly in is also the second embodiment of the present invention. It is an anti-loosening and anti-theft combination nut on the flange surface.

[0024] The structure of a kind of nut washer assembly of the present invention is as Fig. 2, image 3 ,Figure 4, Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown: it is composed of a nut 1 and a washer 2'. Several notches 3a and 3b' are respectively provided on the edges of the nut 1 and the washer 2'. One end of the nut 1 is hexagonal, and the other end of the nut 1 has The flange surface 1f, a cylindrical ring 1e is integrally formed under the flange surface 1f, and a wedge-shaped inclined surface 1a' arranged at an equal angle and with one side high and the other side low as an inclined push surface is arranged between the cylindrical ring 1e and the edge of the nut. At the same time, each w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com