Super black WNN of active azo dye and preparation thereof

A technology of azo dyes and reactive dyes, applied in the direction of azo dyes, reactive dyes, organic dyes, etc., can solve problems such as insufficient depth, low color fixation rate, and unfulfilled blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

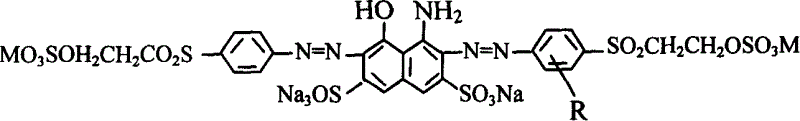

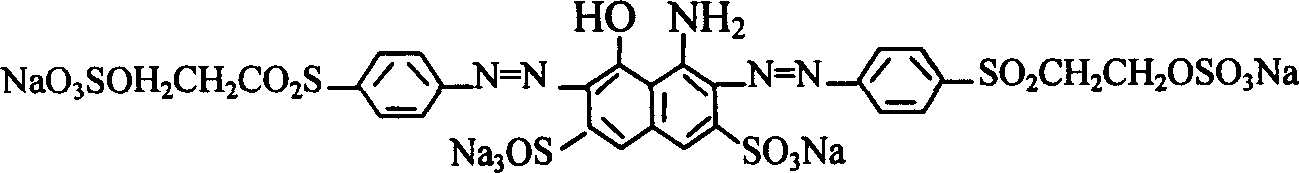

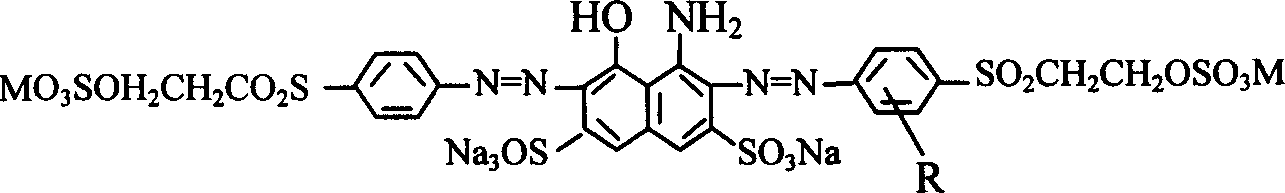

Image

Examples

Embodiment 1

[0032] Example 1: Weigh 16.8 parts of H acid and 34.5 parts of diazonium salts containing sulfonic acid groups or ethyl sulfone sulfate aniline compounds and couple at 0-15°C and pH=1.5-6.5 to prepare a partial Green light navy blue dye.

Embodiment 2

[0033] Embodiment two: the navy blue dye that embodiment one makes is mixed with WNN yellow, WNN crimson by weight ratio 75-80: 5-10: 20-10 to obtain jet black degree deep, good alkali resistance and salt stability , good reproducibility, good level dyeing, high lifting power, can not only dye and print, but also can be dyed super black WNN, the dye strength is higher than C.I reactive black 5, KN-G2RC black, BED black, ARC black , BES black is 15%-30% higher.

[0034] Table I

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com