Method of making bicycle saddle using sewing or split joined saddle surface vacuum suction moulding

A bicycle saddle and vacuum forming technology, which is applied to bicycle saddles, bicycle accessories, applications, etc., can solve the problems of low work efficiency, the saddle is easy to absorb water and wet the rider's pants, and the shape is easy to change. Improve work efficiency, solve the problem of water absorption of the saddle, and increase the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention relates to a method for preparing a bicycle saddle by vacuum-absorbing the saddle surface sewn or spliced. Its process steps include in turn:

[0014] - sewing or joining saddles,

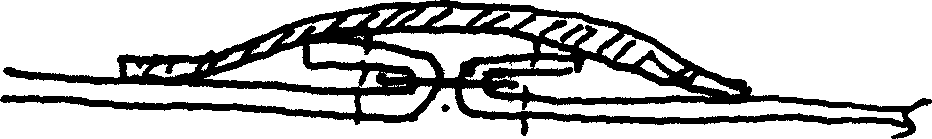

[0015] - apply sealing tape and heat press or apply sealant to the seam line or seam on the back of a sewn or spliced saddle, see figure 1 ,

[0016] ——Fix the front side of the sewn or spliced saddle covered with sealing tape or sealant on the mold, and use the negative pressure generated by the vacuum in the mold to absorb the sewn or spliced saddle into the cavity of the mould,

[0017] ——Inject the foam material into the cavity of the mould.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com