Air-cooled absorption type refrigerating plant

An absorption refrigeration and air-cooling technology, which is applied in the direction of adsorption machines, boiler absorbers, absorbents/adsorbents, etc., can solve the problems of ensuring the maintenance space, the difficulty of ensuring the suction space of the air suction port, and the enlargement of the device body. Achieve the effect of ensuring the heat radiation area, reducing air resistance, and reducing the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the best embodiment of the invention of the present application will be described with reference to the attached drawings.

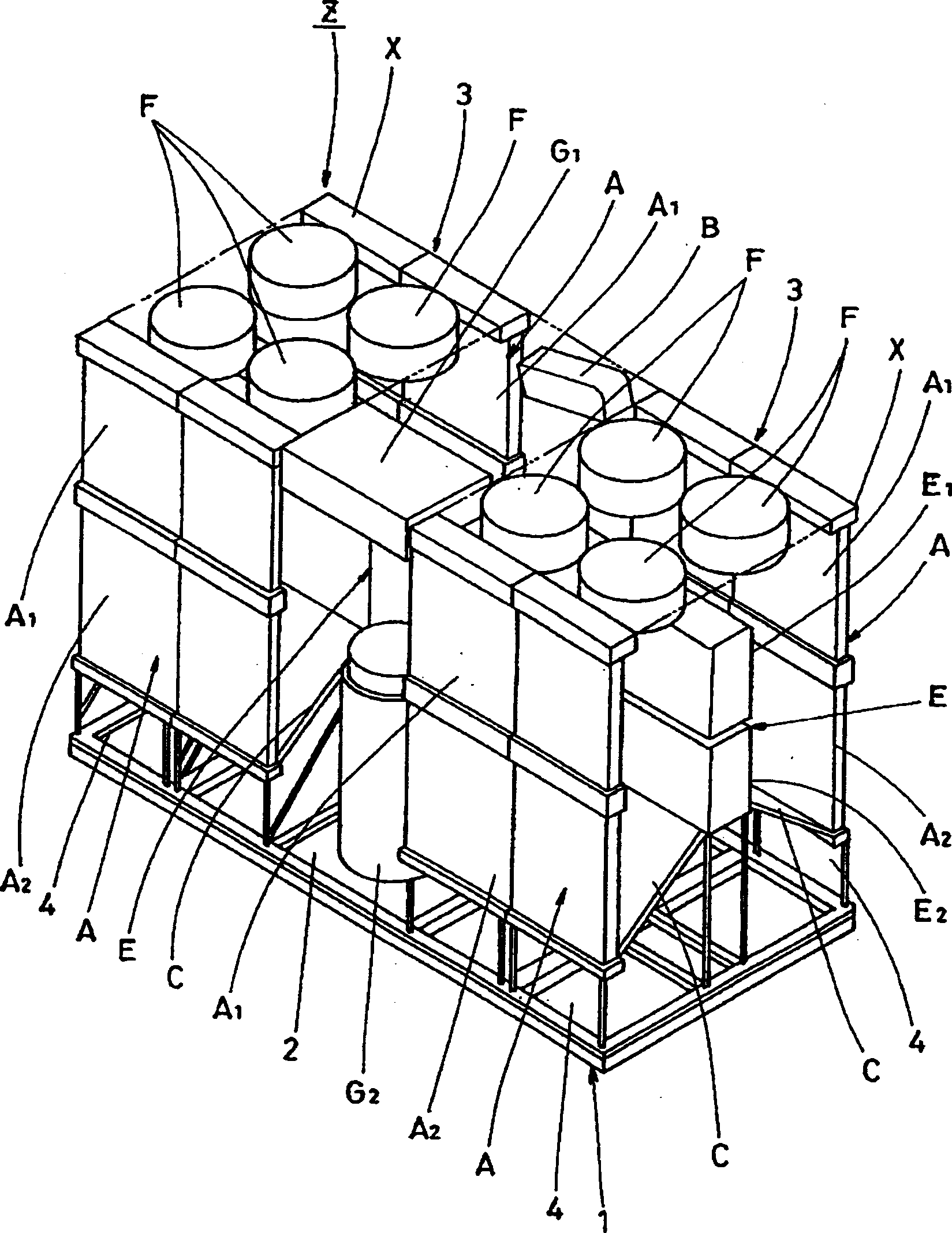

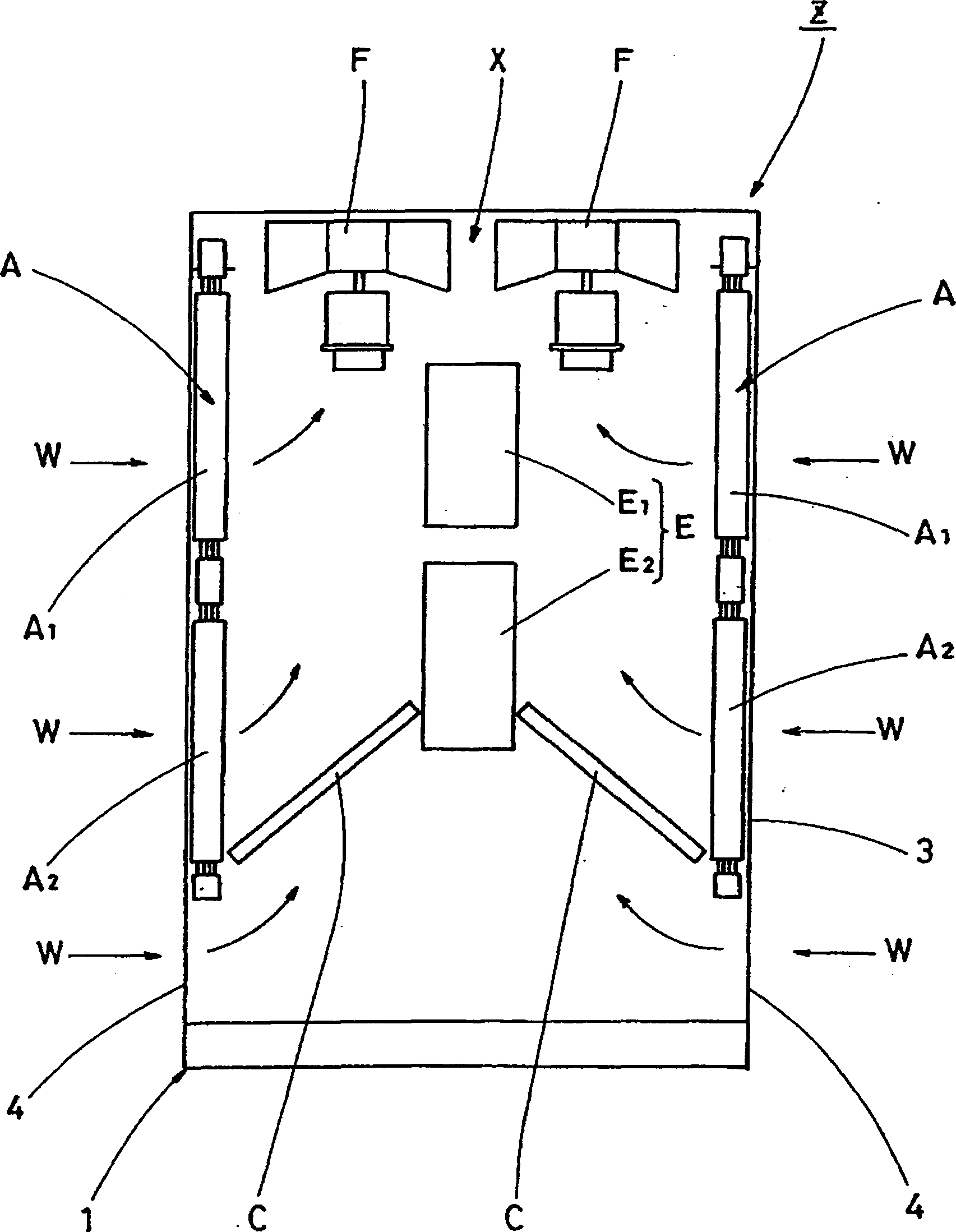

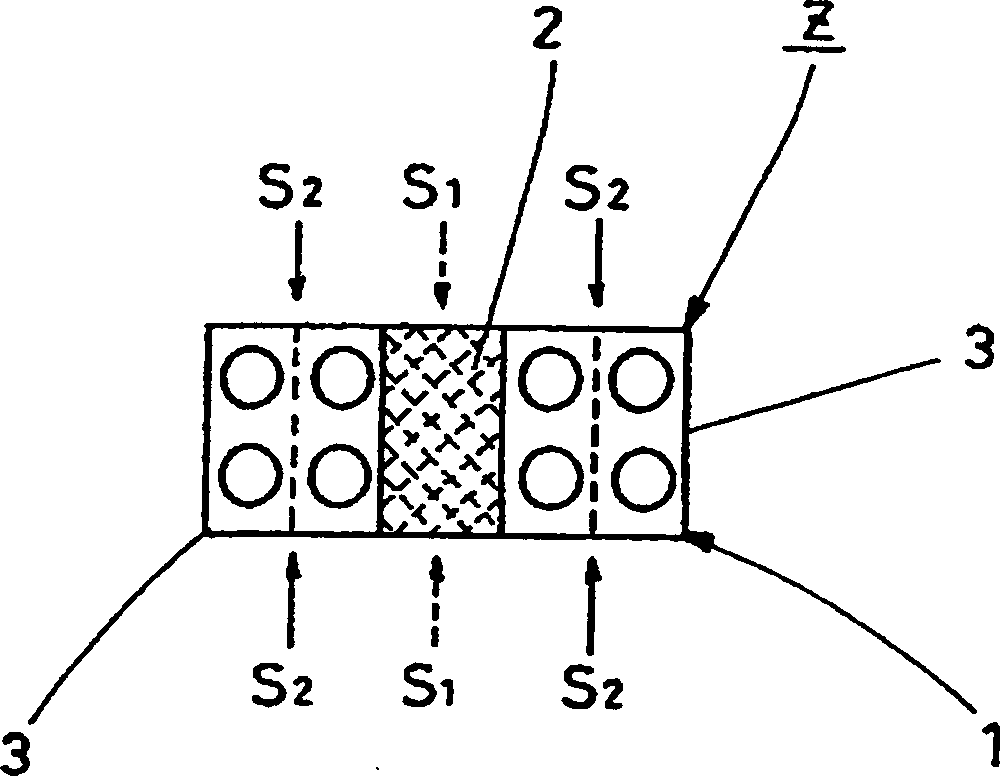

[0035] This air-cooled absorption freezer, such as figure 1 and figure 2 As shown, it includes: a machine room 2 located in the center of the longitudinal direction of the approximately cuboid device body 1 and air cooling and heat exchange parts 3 and 3 arranged on both sides of the machine room 2 in the longitudinal direction.

[0036] In the above-mentioned machine room 2, there are disposed: a high-temperature regenerator G2 located at the lower stage on one side of the device body 1, a low-temperature regenerator G1 located at the upper stage, and a heating chamber located at the upper stage on the other side of the device body 1. heat exchanger B. And, between this machine room 2 and the air cooling and heat exchanging parts 3, 3, although not shown in the figure, a partition wall is provided. This facilitates maintenance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com