Structure of water quality sensor of washing machine

A technology for sensing devices and washing machines, which is applied in the field of washing machines, and can solve problems such as difficult alignment of connecting parts 42, difficult installation of connection flanges 36, cumbersome installation of water quality sensing devices 9, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

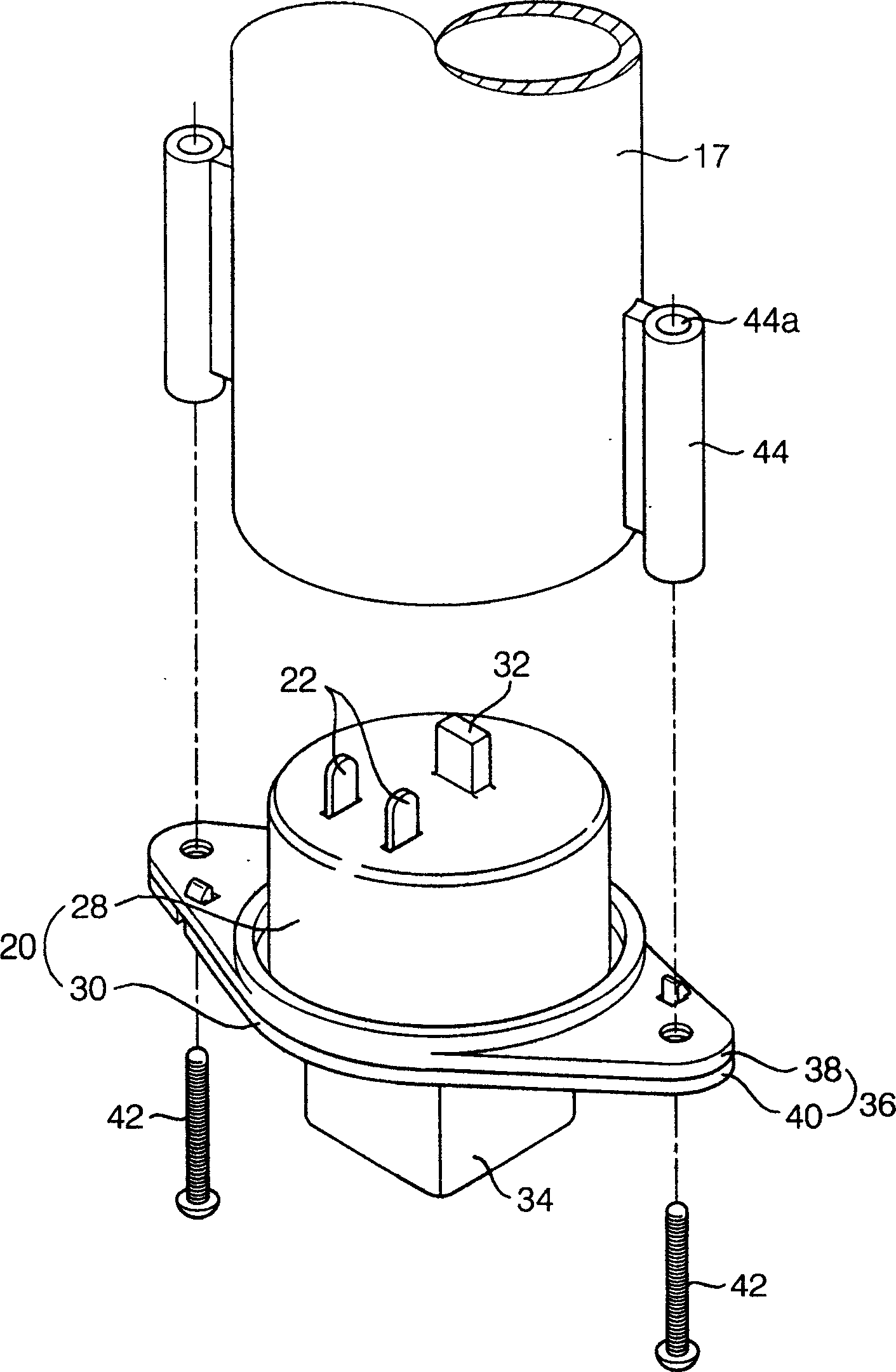

[0046] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail: Figure 4 It is a cross-sectional view of the water quality sensing device for a washing machine of the present invention. Figure 5 It is an exploded schematic view of the water quality sensing device of the washing machine in the present invention.

[0047] Such as Figure 4 and Figure 5As shown, the structure of the washing machine water quality sensing device of the present invention has the following parts: the outer tub 52 for washing water; the air chamber 54 that allows the washing water to flow from the outer tub 52 under the side of the outer tub 52; The open pipe formed on the bottom of 54 is used to detect the water quality sensing device 56 of the water quality of the washing water in the air chamber 54; Positioning vane 58; on one side of the outer tub, when the water quality sensing device 56 is installed incorrectly, it prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com