Eleastic expansion meshing body pile connecting end plate and prefab

A prefabricated and elastic technology, applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as incomplete butt joints and sinking of pipe piles, and achieve the elimination of broken piles, accurate distribution, and integrity and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

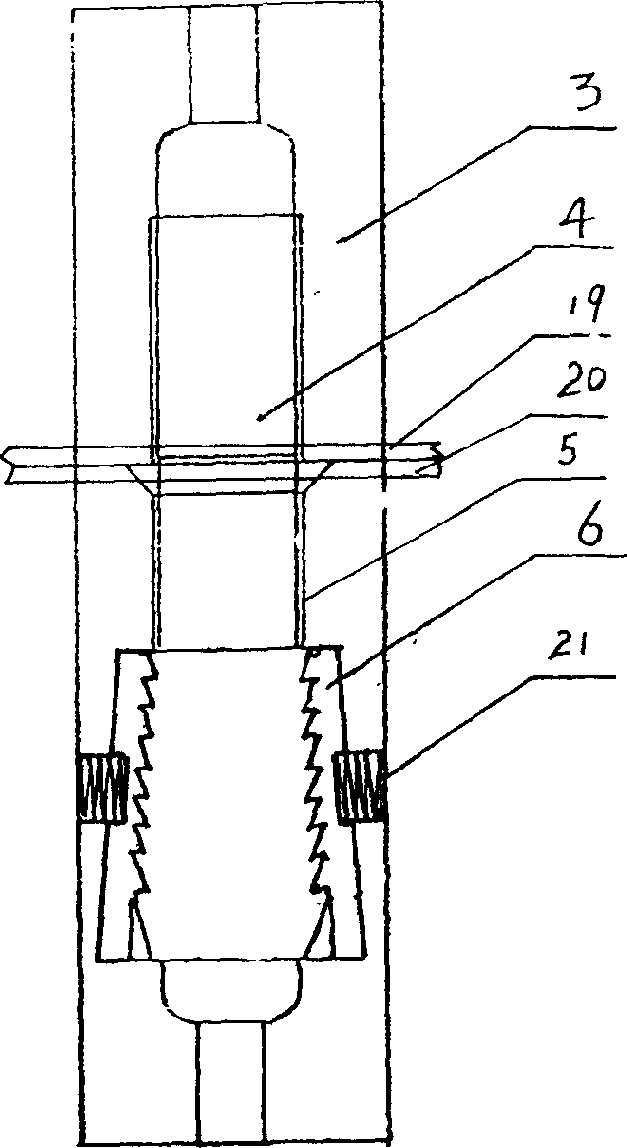

[0016] Embodiment 1: with reference to attached Figure 1~6 . Elastic expansion engaging body piling end plate, which includes end plates 19 and 20, 2 or more expansion nuts 3 are distributed on the end plate 19, and the screw segments in the engagement screws 4 are screwed on the expansion nuts 3 Inside, two or more top pull nuts 5 are circumferentially distributed on the end plate 20, the plug-in meshing tooth sleeve 6 is located in the expansion cavity 10 of the top pull nut 5, and the outside of the plug-in mesh tooth sleeve 6 is connected to the top pull nut There is a spring 21 between the 5 walls, usually a compression spring, one end of the compression spring 21 is located in the hole in the wall of the top pull nut 5 and is in contact with the rivet at the end of the wall hole of the top pull nut, and the other end is in contact with the plug-in meshing tooth sleeve The outer sides are in contact, and when docking, the plug-in meshing sleeve 22 is located in the expa...

Embodiment 2

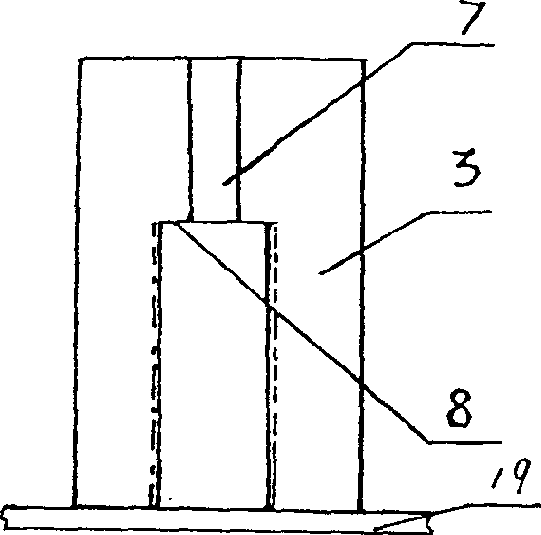

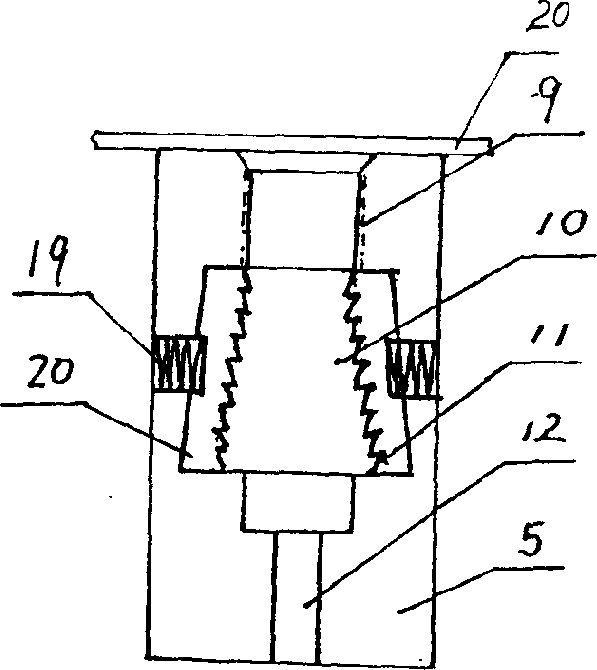

[0017]Embodiment 2: with reference to accompanying drawing 7. On the basis of Embodiment 1, the prefabricated part composed of elastic expansion engagement body pile end plates, the two ends of the prefabricated part 17 are respectively equipped with end plates 19 with a plurality of tension nuts 3 and with a plurality of top pull nuts. The end plate 20 of the nut 5, the headers 2 at both ends of the longitudinal steel bars 18 in the prefabricated part 17 are respectively clipped on the steel bar header clamps 8 and 11 in the expansion nut 3 and the top pull nut 5, and meshed Screw 4 is used for the docking between two prefabricated parts 17. The screw section of the engagement screw 4 is screwed into the tension nut 3, and the engagement section of the engagement screw is inserted into the plug-in engagement gear sleeve 20 in the top pull nut and elastically engages with the insertion engagement gear sleeve (the engagement screw 4 is in the pipe pile When docking with the pi...

Embodiment 3

[0018] Embodiment 3: with reference to accompanying drawing 8. On the basis of Examples 1 and 2, the butt joint structure between the prefabricated part and the prefabricated part composed of the elastic expansion engaging body pile end plate, the ends of the two prefabricated parts to be butted are respectively equipped with top tension expansion bolts. The end plate of the cap and the end plate with the expansion nut, the opening of the expansion nut on the end plate of one preform is opposite to the opening of the expansion nut on the end plate of the other preform, and engage The screw section of the screw is screwed into the threaded buckle of the pull-up nut, and the meshing tooth section of the meshing screw is inserted into the plug-in meshing sleeve in the top-pull nut and elastically engages with the plug-in meshing sleeve to complete the prefabricated part and the prefabricated connection between pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com