Blowing-carding-drawing vibratory cotton basket

A blowing-carding and vibrating technology, which is applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve the problems of poor service conditions, high operating costs, complex structure, etc., and achieves convenient operation, uniform cotton output, overcoming the effect of volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

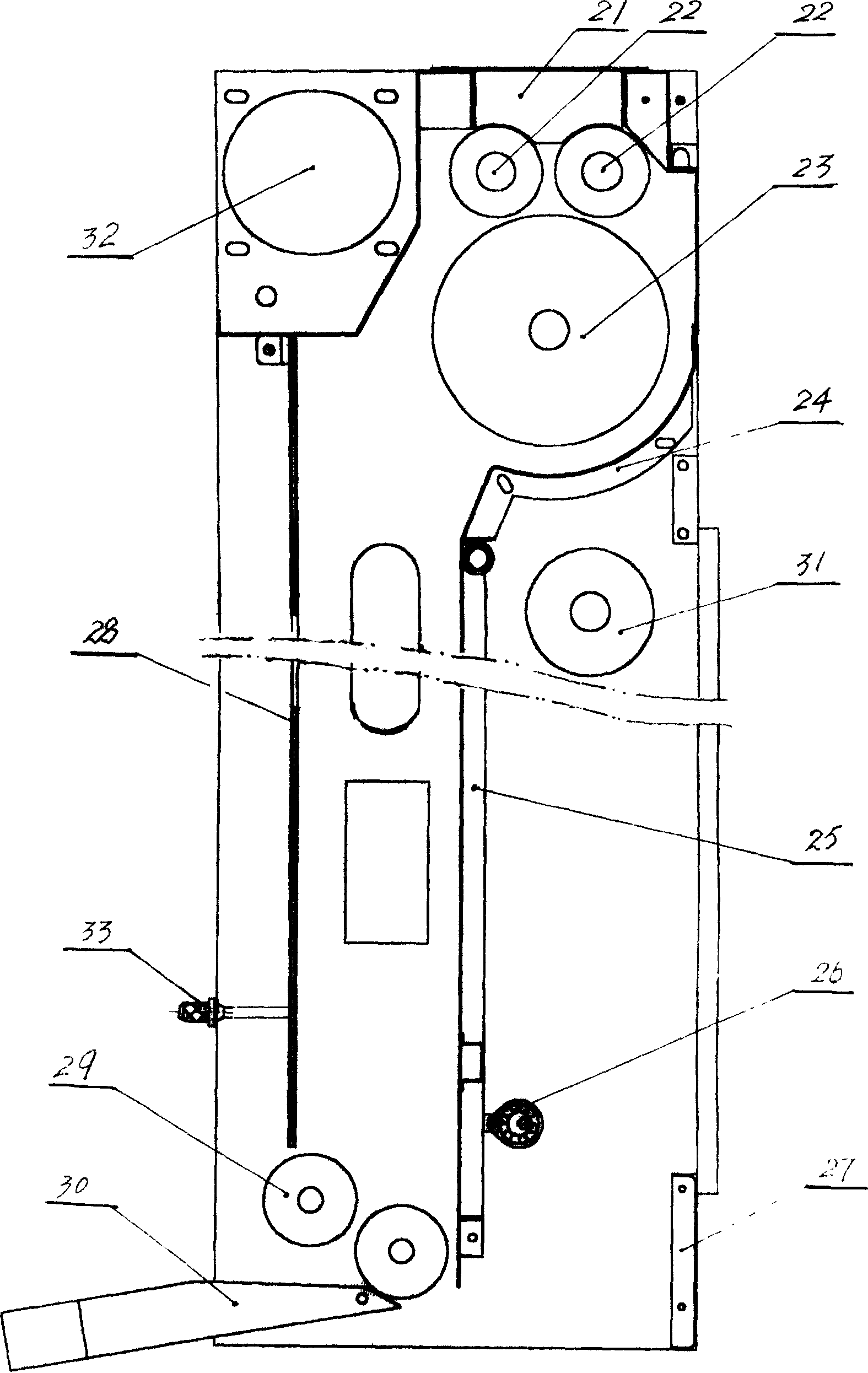

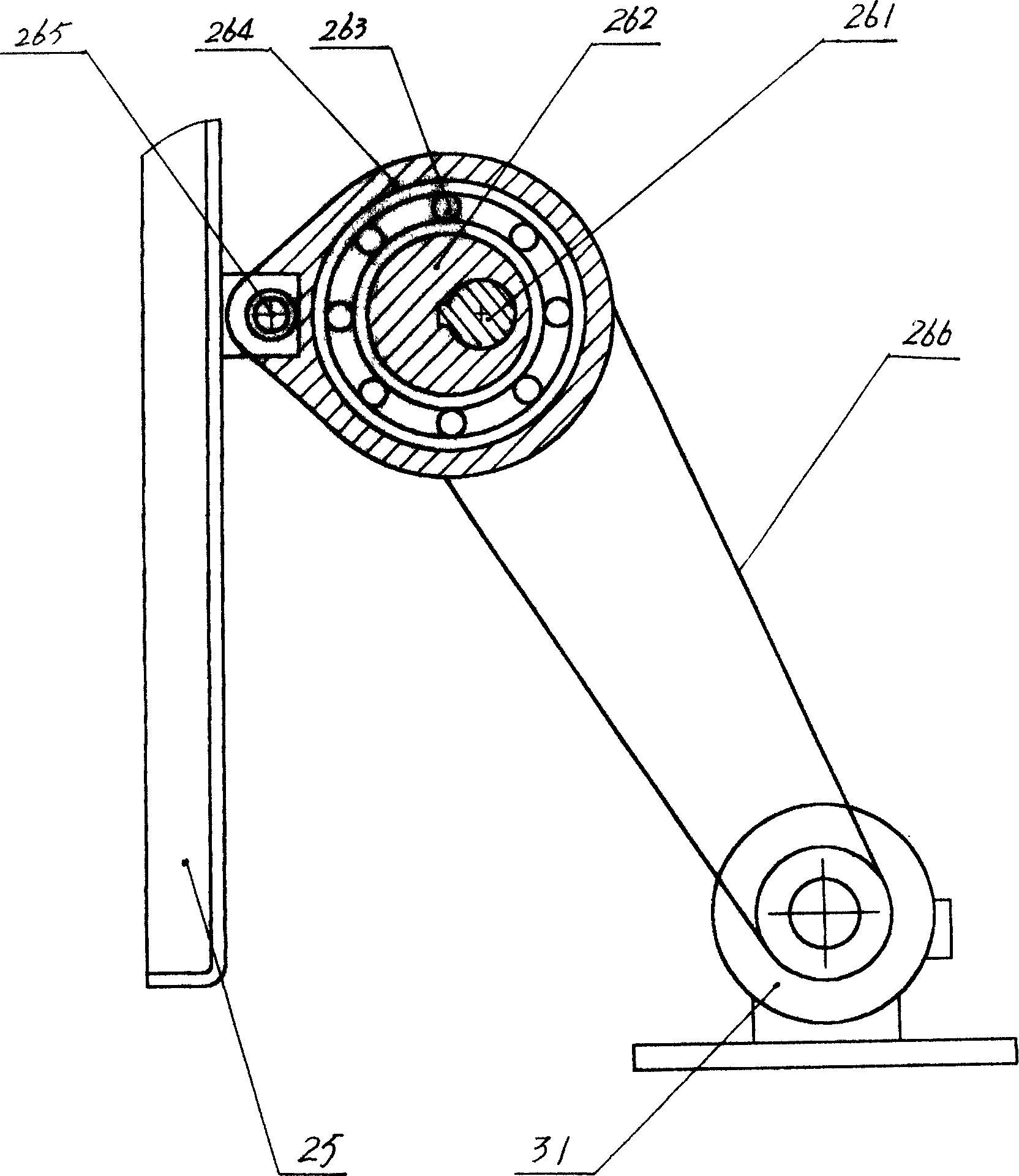

[0016] The cleaning and carding vibrating cotton box of the present invention is made up of a cotton head 1, a vibrating cotton box 2 and a frame 4, and the vibrating cotton box 2 includes a nodding port 21, a cotton feeding roller 22, a cotton stripper 23, Curved surface sealing plate 24, vibrating plate 25, swing mechanism 26, cotton box shell 27, front baffle plate 28, cotton output roller 29, cotton dripping plate 30, cotton stripping motor 31, cotton feeding motor 32, a pair of cotton feeding rollers 22 Horizontally arranged below the nodding port 21, the cotton stripper 23 is arranged below the two cotton feeding rollers 22, the axis of the cotton stripping beater 23 is located on the vertical bisector of the centerlines of the two cotton feeding rollers 22, and the curved surface sealing plate 24 is arranged on the lower right side of the cotton stripper 23, the front baffle 28 and the vibrating plate 25 can be rotatably installed on the cotton box housing 27, and the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com