Pulling force auxiliary apparatus for changing main steel cable of elevator

An additional device, the technology of the main steel cable, applied in the direction of transportation and packaging, elevators, etc., can solve problems such as increased self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

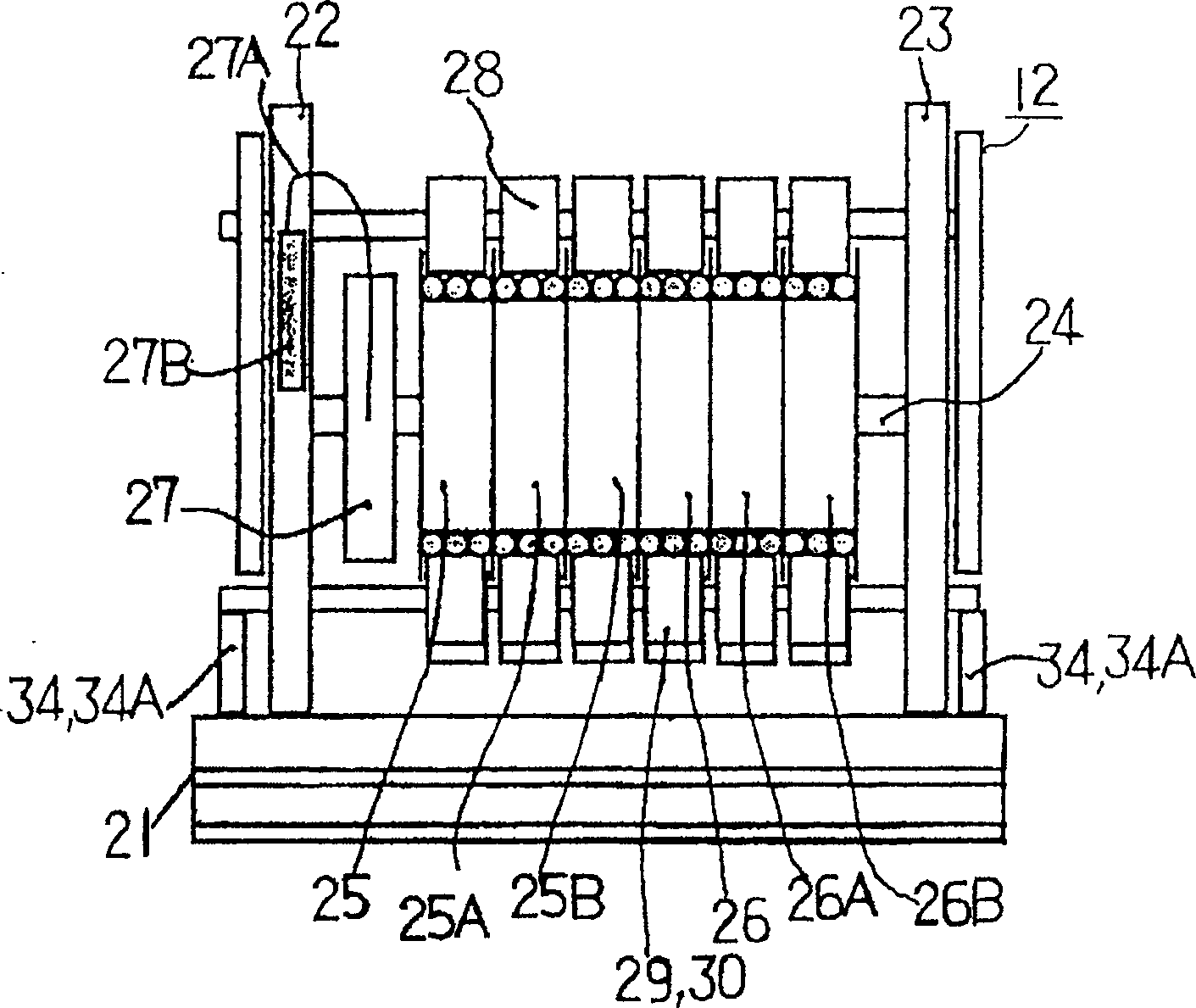

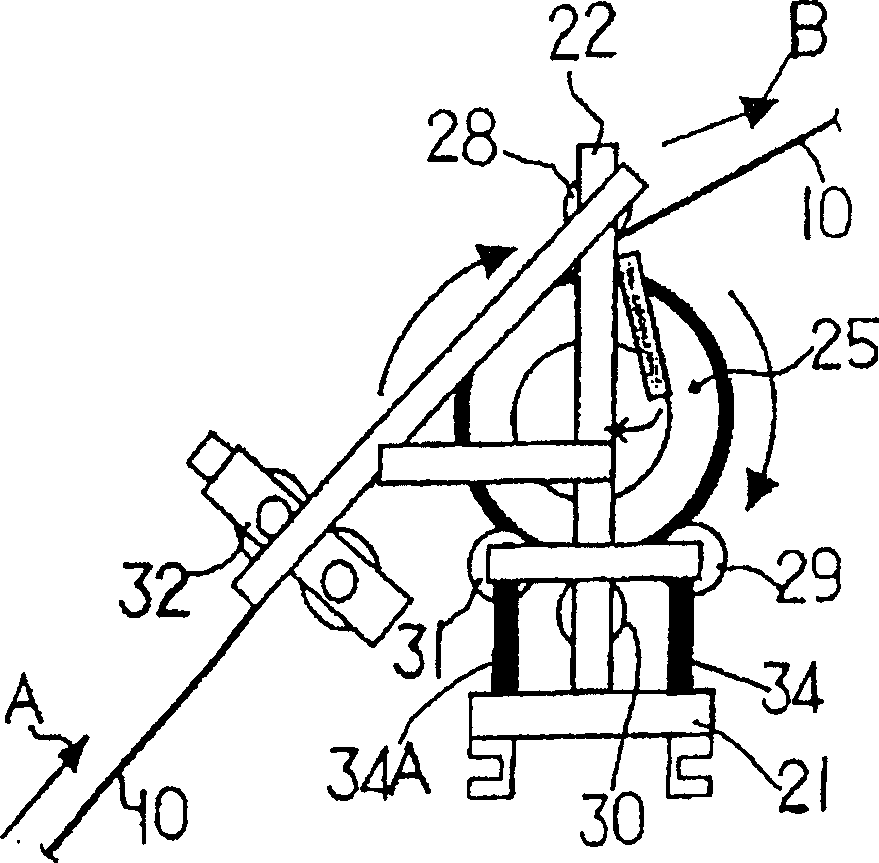

[0018] Embodiments of the main rope replacement tensioning device for an elevator according to the present invention will be described below with reference to the drawings.

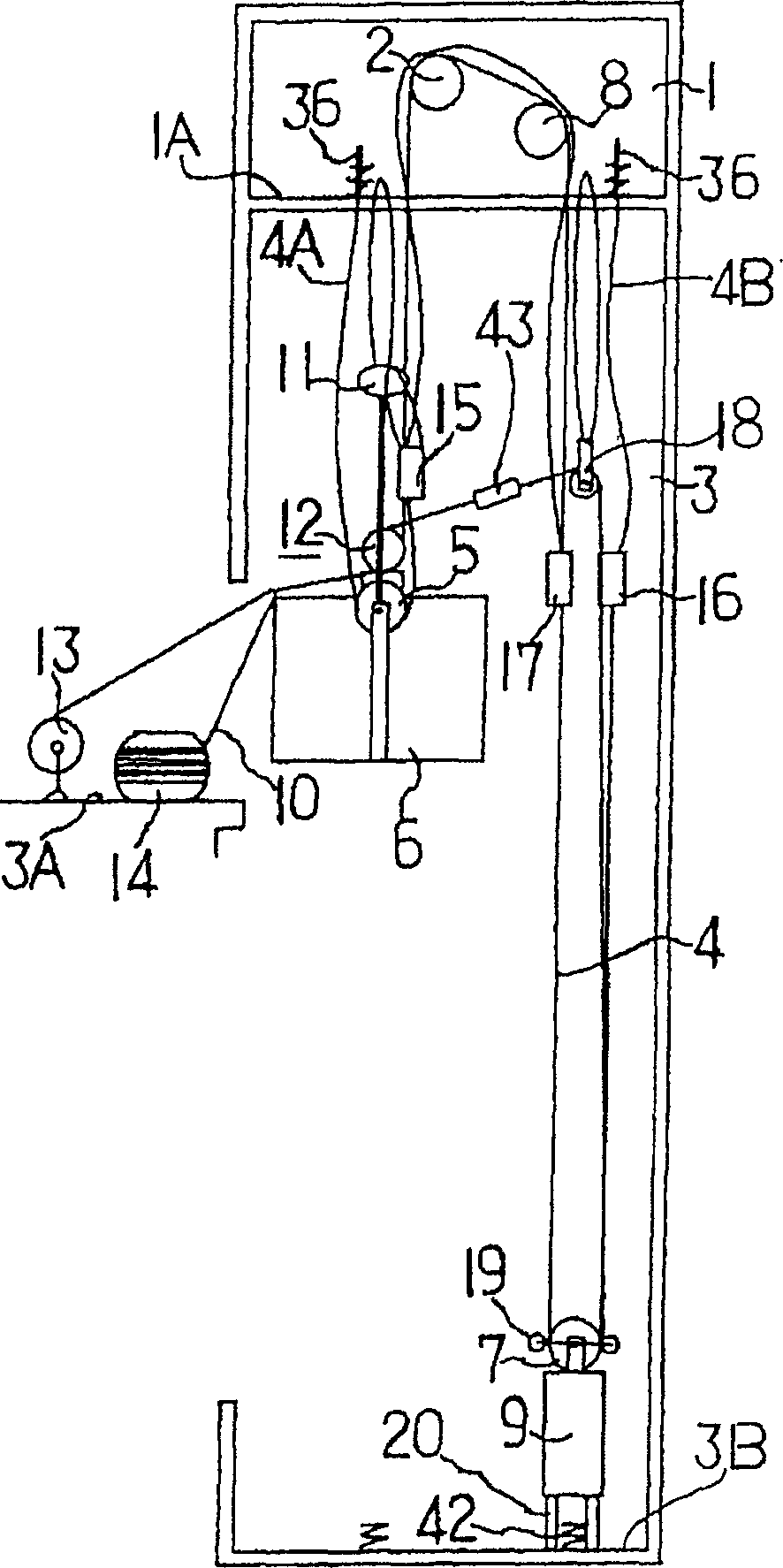

[0019] figure 1 The elevator of the shown embodiment is a 2-to-1 roped elevator, and it is equipped with: it is wound on the sheave 2 of the hoist installed in the machine room 1, and its one end 4A and the other end 4B are supported and fixed. A plurality of established main steel cables 4 on the floor of the machine room 1; between an end 4A of the established main steel cables 4 and the winch wheel 2 of the winch, a riding box cooperating with the established main steel cables 4 The riding box 6 supported by the pulley used; between the other end 4B of the established main steel cable 4 and the cable pulley 2 and the deflector wheel 8 of the winch, the reverse pulley 7 coordinated with the established main steel cable 4 Supported counterweight 9.

[0020] exist figure 1 On the elevator of the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com