Composite RE body finishing machine

A complex and rare earth technology, which is applied to surface polishing machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problem that the workpiece cannot be broken and rusted, and fragile and rusty rare earth complexes cannot be used. problem, achieve the effect of small impact force, prevent oxidation, prevent breakage and rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

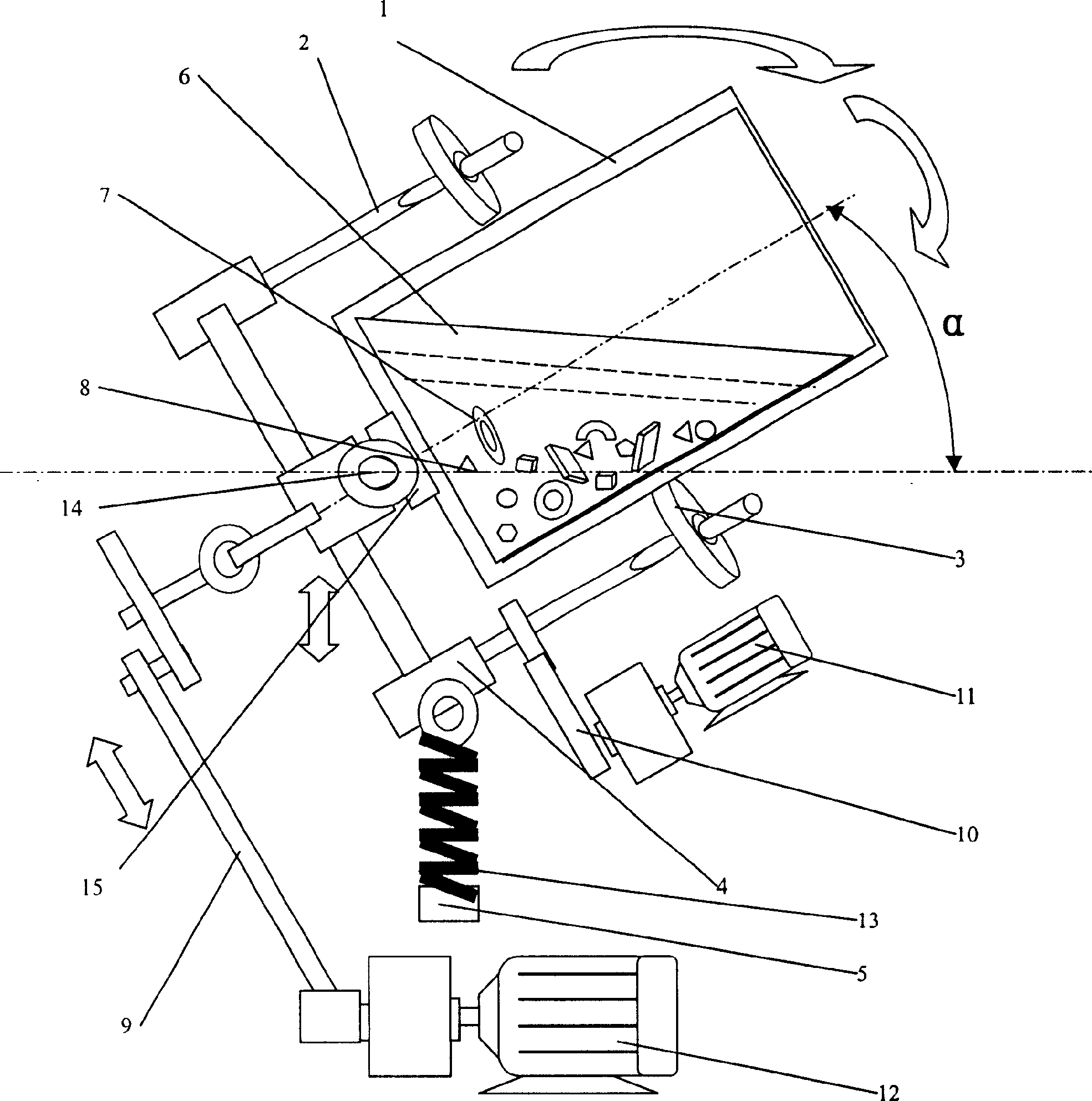

[0020] The cross-sectional shape of the material barrel 1 is circular, and the size of the cross-section remains unchanged from the bottom of the material barrel to the mouth of the material barrel. The bottom and sides of the bucket 1 are in a sliding arc shape. The central axis of the barrel 1 is provided with an angle α with the horizontal line, and α is 15°. A cover is installed on the mouth of the material barrel, and when the material barrel is working, the cover tightly seals the mouth of the material barrel. The material of the lid and the bucket 1 is hard plastic.

[0021] The support frame includes a support rod 2, a support wheel 3, and a support frame 4, and its material is a metal material. The support rods 2 are installed on the support frame 4 and distributed around the barrel 1 . A support wheel 3 is sheathed on the support rod 2, and the support wheel 3 is in contact with the barrel 1. There is a set of support rods 2 and support wheels 3 directly below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com