Spherical universal pipe joint made of synthetic resin

A universal pipe and sleeve joint technology, applied in the field of universal pipe joints, can solve the problems of top side protrusion, dirt retention, undesired and other problems, and achieve the effect of small displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail using the first, second and third embodiments shown in the drawings.

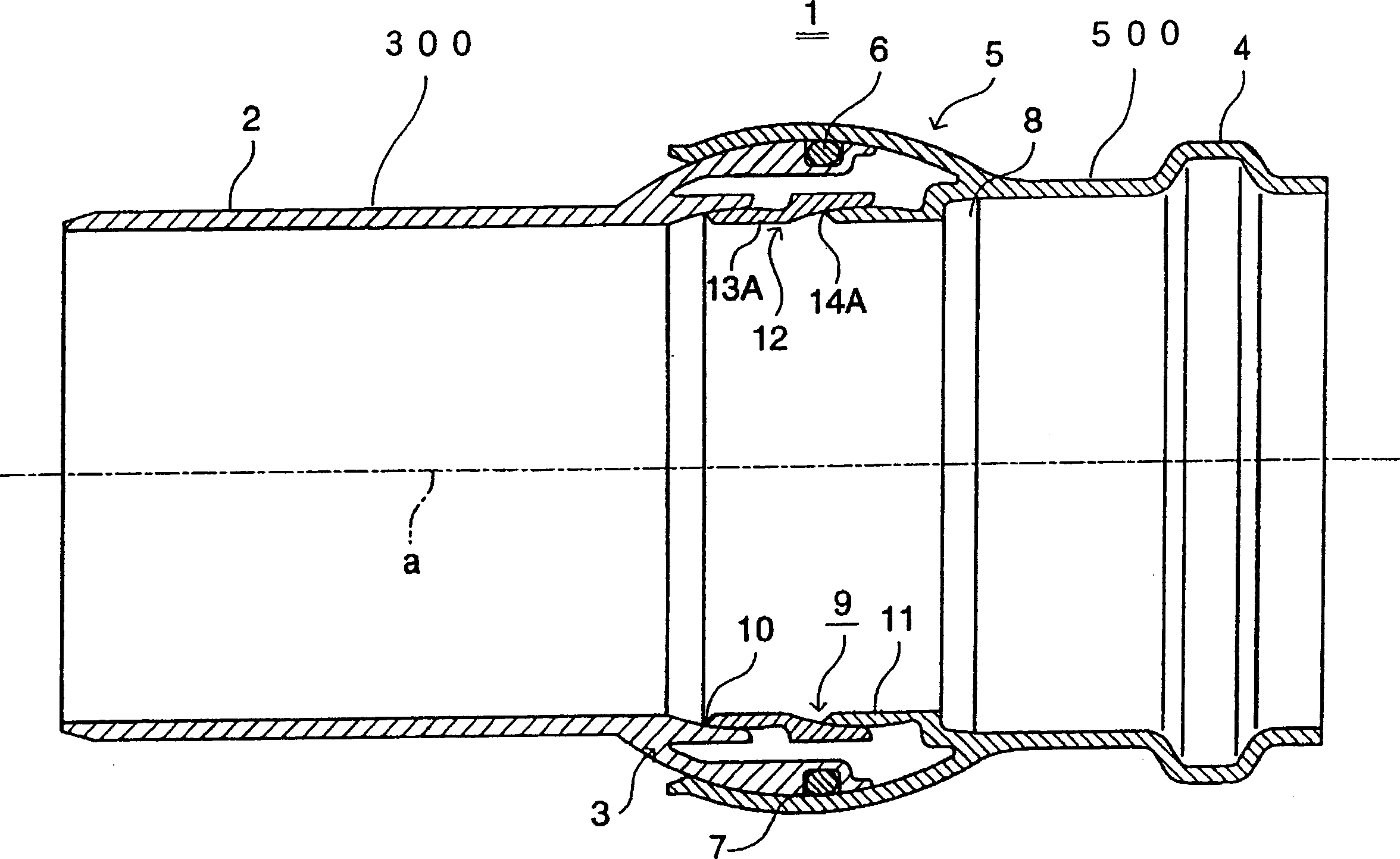

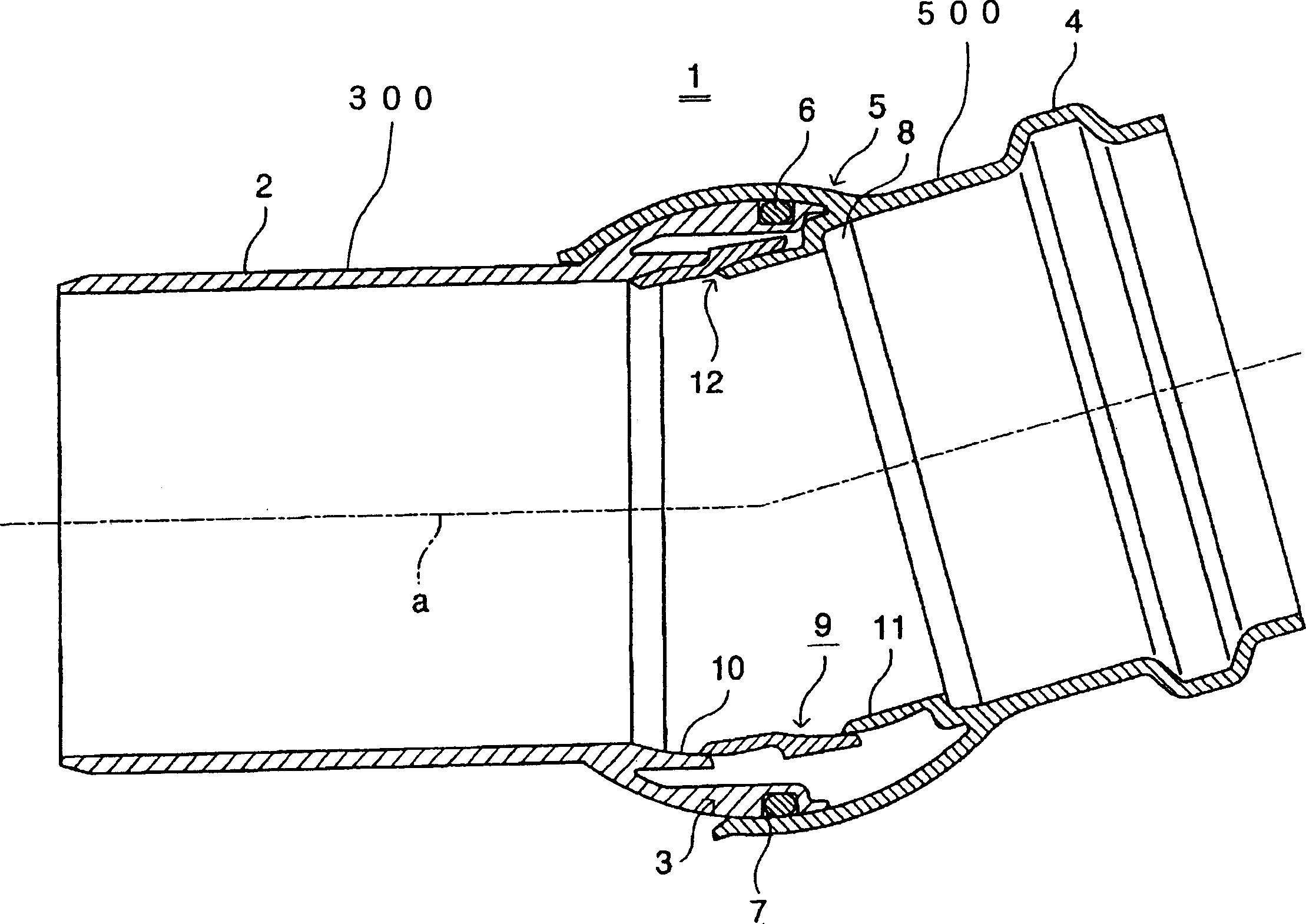

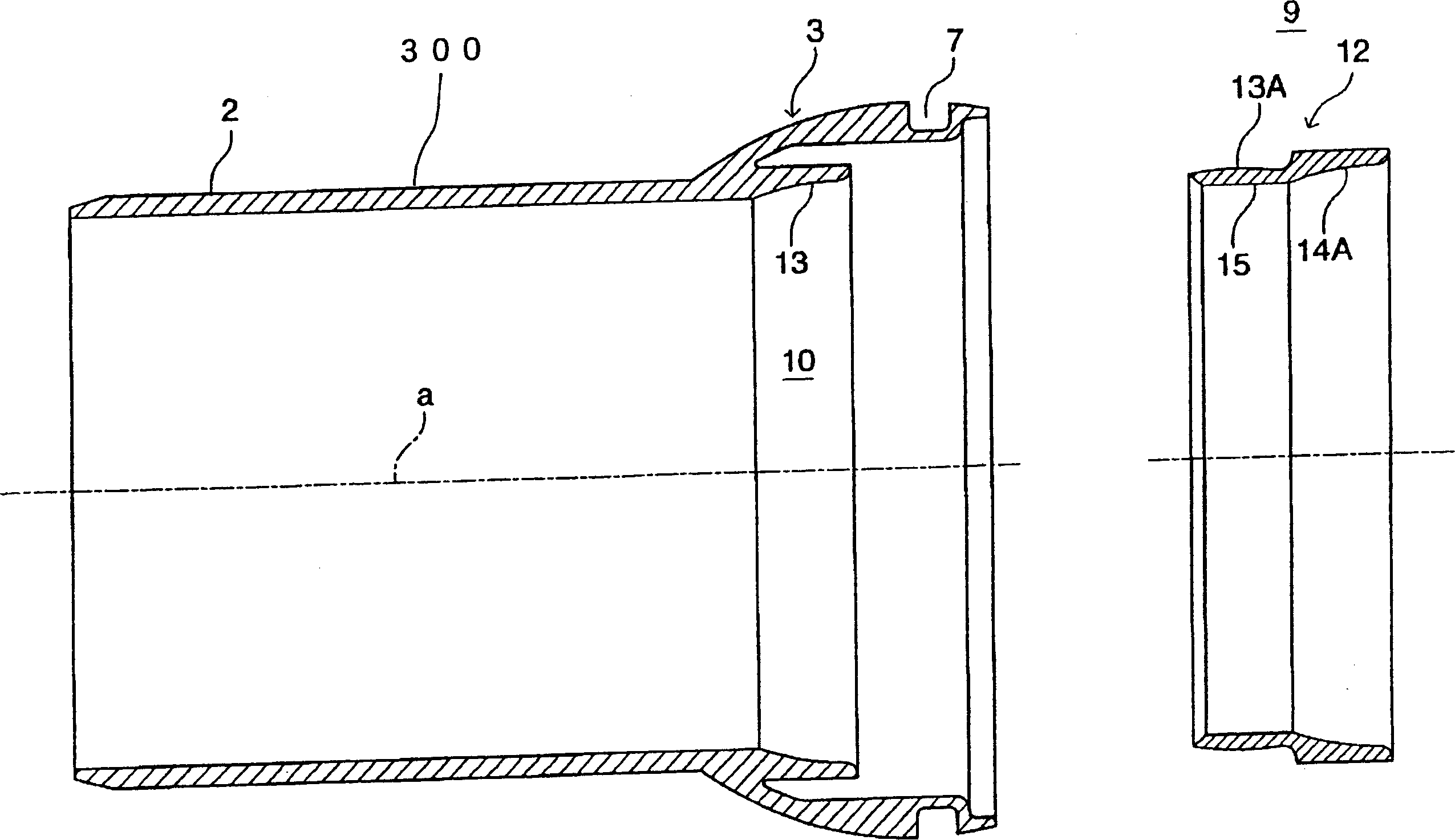

[0044] figure 1 is a sectional view of the first embodiment of the present invention, figure 2 yes figure 1 The usage state diagram, image 3 and Figure 4 yes figure 1 dissected view of the Figure 5 is a sectional view of the second embodiment, Figure 6 It is a sectional view of the third embodiment.

[0045] An embodiment of the present invention is a universal pipe joint for connecting PVC pipes or PVC pipes and PVC water buckets, comprising: a sleeve joint integrally formed with the connection port and having a partially spherical inner surface sleeve; and On the opposite side, it consists of another connection port with the same linear tube axis or a socket joint that is integrally formed with the mouth of the bucket body and has a partially spherical outer surface plug. It is a universal joint that can flexibly and slidably fit thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com