Apparatus for checking the dimensional and geometric features of pins

A technology of geometric features and equipment, applied in metal processing equipment, grinding/polishing equipment, parts of grinding machine tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

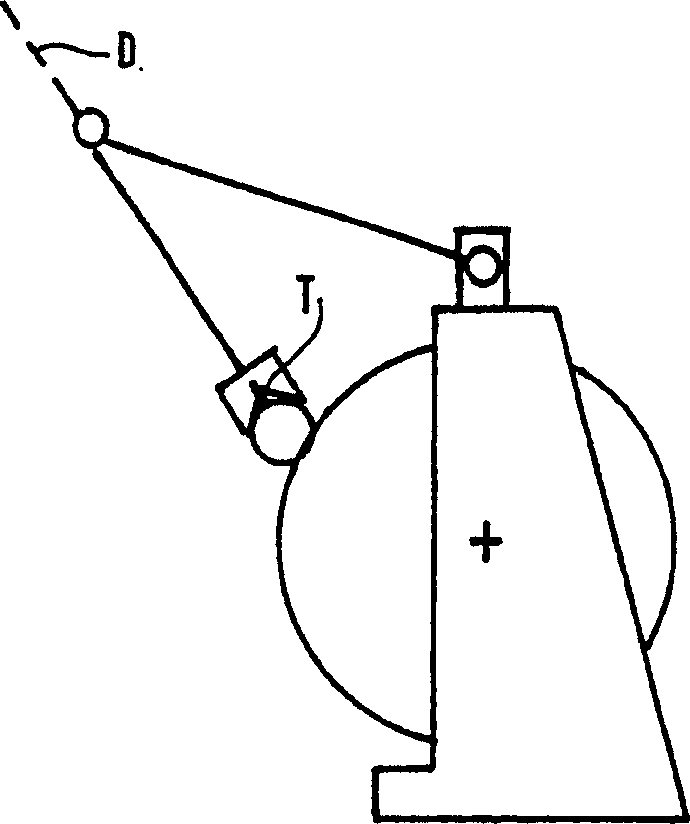

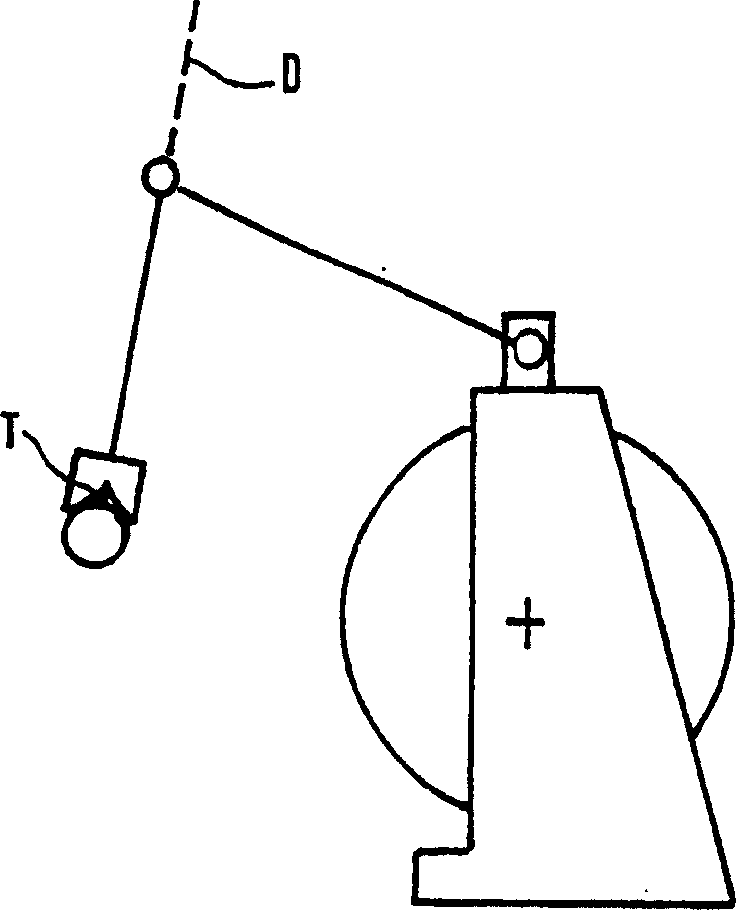

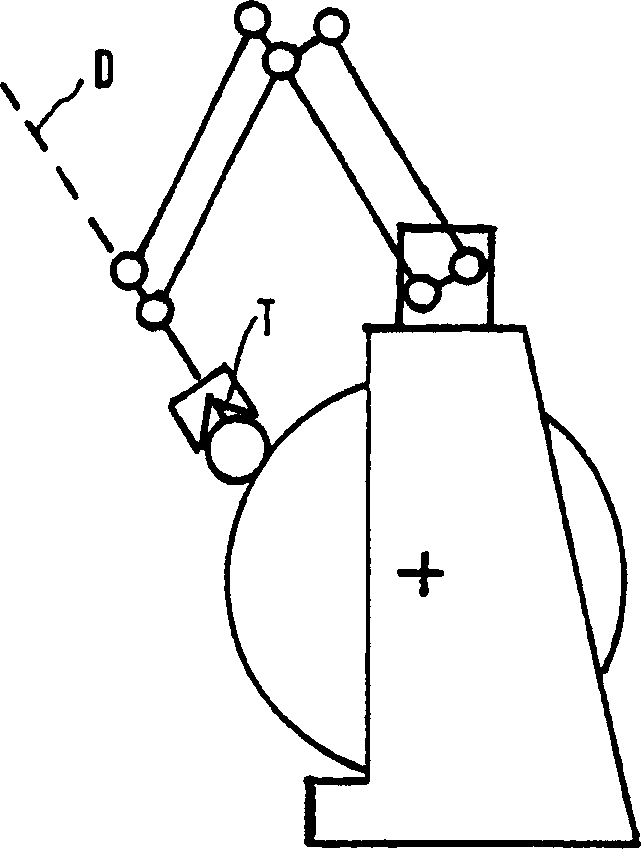

[0018] refer to image 3 , 4 and 5, a grinding wheel slide 1 of a computer numerically controlled ("CNC") grinding machine for grinding crankshafts supports an arbor 2 defining an axis 3 of rotation of a grinding wheel 4. The grinding wheel slide 1 carries a support device with a fixed support 5 and a connecting device comprising several connecting parts. More specifically, the support 5 supports the first rotary connection 9 via the first rotary pin 6 . The pin 6 defines a first axis of rotation 7 parallel to the axis of rotation 3 of the grinding wheel 4 and to the geometrical axis of rotation 8 of the crankshaft to be inspected. The connecting part 9 then supports the intermediate part 12 via a second swivel pin 10 , wherein the second swivel pin 10 defines a second swivel axis 11 parallel to the shafts 3 and 8 . A third rotating pin 13 is stationary relative to the support 5 and defines a third axis of rotation 14 parallel to the shafts 3 , 8 and 11 , supporting a first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com