Preparation method of acid modified titanium-containing molecular sieve

A technology of molecular sieve and acid modification, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of complicated process, improved catalytic activity, and many processing steps, and achieve easy process and high catalytic activity Improve the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Synthesize TS-1 molecular sieve raw powder according to literature (CN1488438).

[0025] In the first step, the former powder of unroasted TS-1 molecular sieve: the weight ratio=1:50 of acidic compound solution, the concentration of acidic compound solution is 2.0mol / l, and acidic compound is nitric acid; In the second step, the first step The resulting reaction mixture was reacted at 120°C for 20 hours.

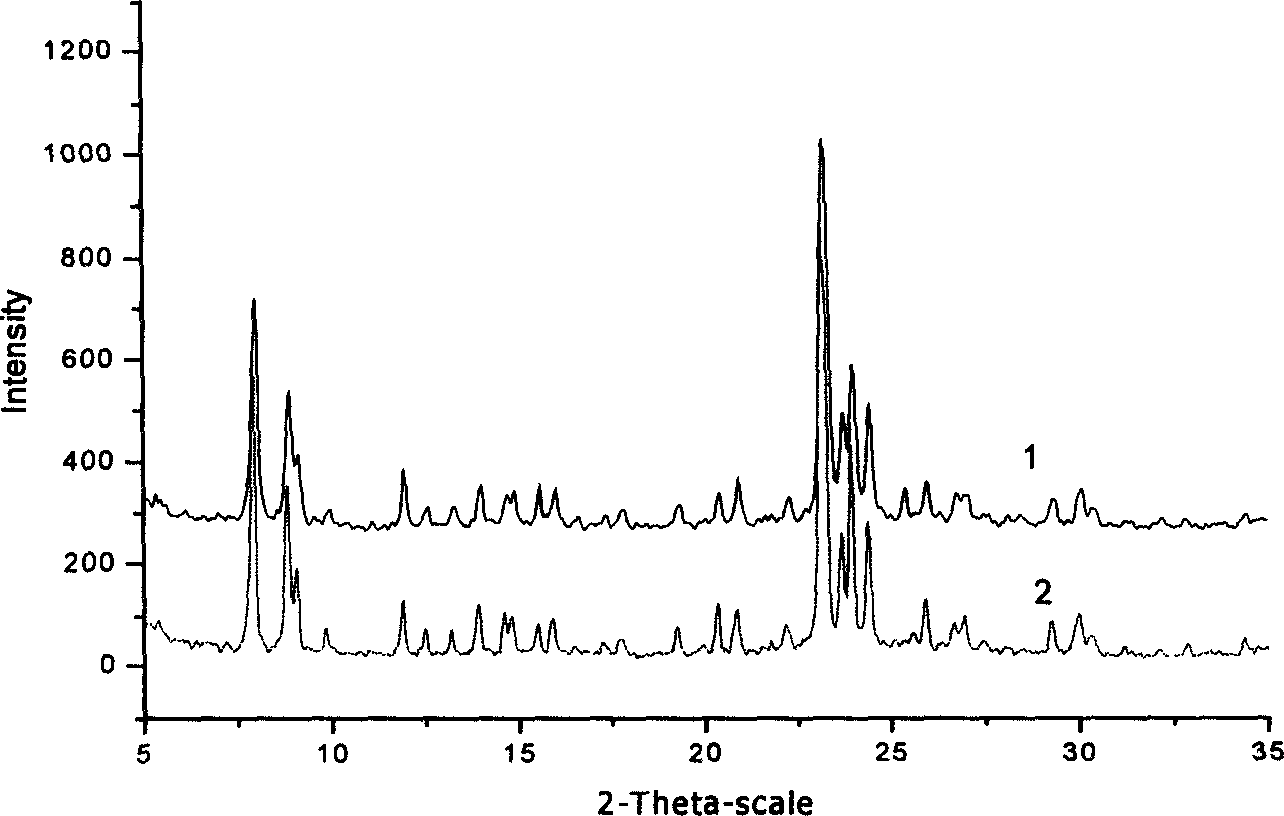

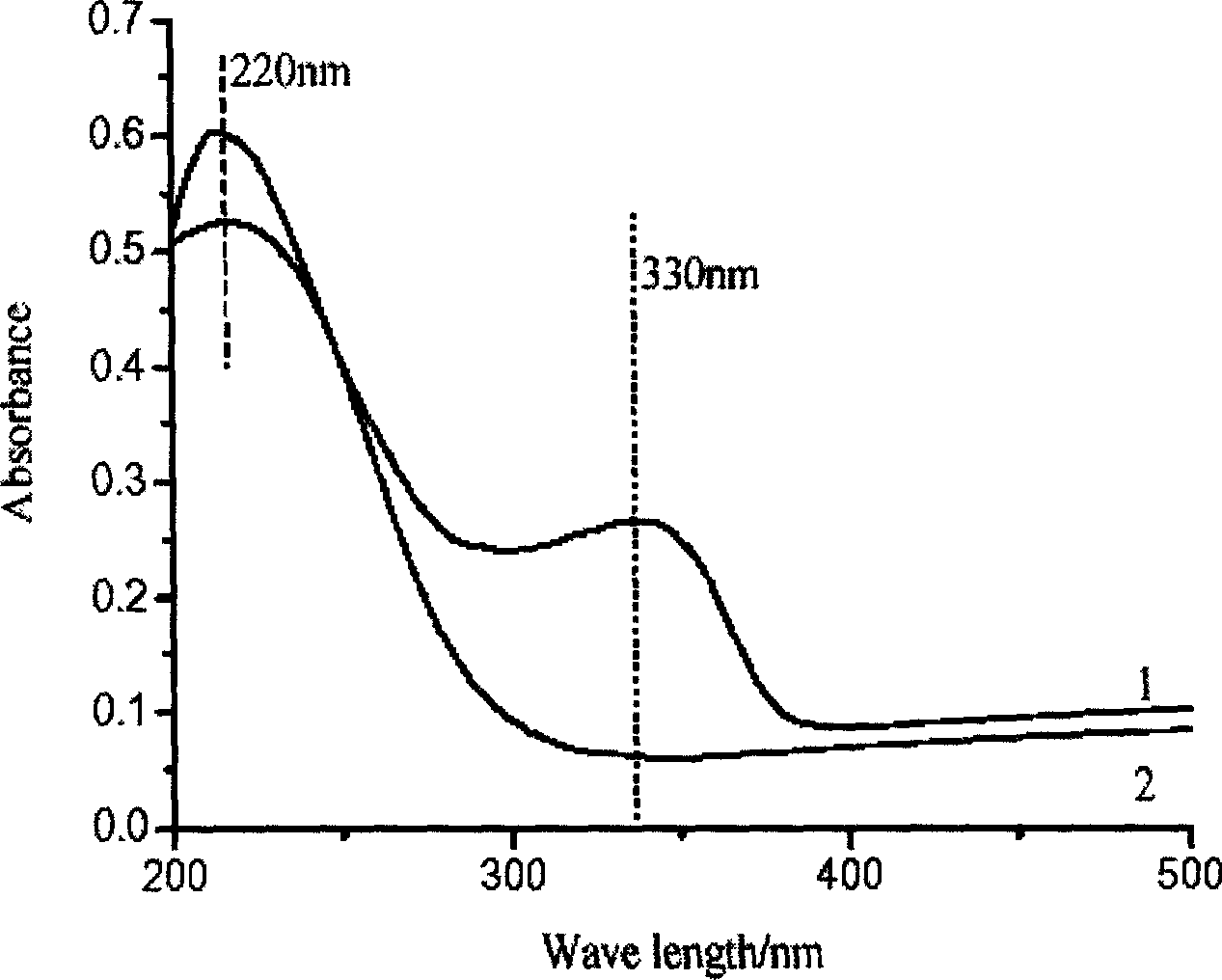

[0026] The XRD spectrum of the acid-modified TS-1 molecular sieve is as follows figure 1 As shown, the UV-Vis spectrum is shown as figure 2 shown.

Embodiment 2

[0028] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0029] In the first step, the concentration of the acidic compound solution was 0.2 mol / l; in the second step, the reaction mixture prepared in the first step was reacted at 150° C. for 30 hours.

[0030] The XRD spectrum of acid-modified TS-1 molecular sieve and figure 1 Similarly, a UV-Vis spectrum with figure 2 similar.

Embodiment 3

[0032] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0033] In the first step, the concentration of the acidic compound solution was 6.0 mol / l; in the second step, the reaction mixture prepared in the first step was reacted at room temperature for 1.0 hour.

[0034] The XRD spectrum of acid-modified TS-1 molecular sieve and figure 1 Similarly, a UV-Vis spectrum with figure 2 similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com