Magnetron

A magnetron and anode technology, applied in the field of magnetron, can solve the problems of failure to improve oscillation efficiency and deterioration of oscillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, preferred embodiments of a magnetron according to the present invention will be described in detail with reference to the accompanying drawings.

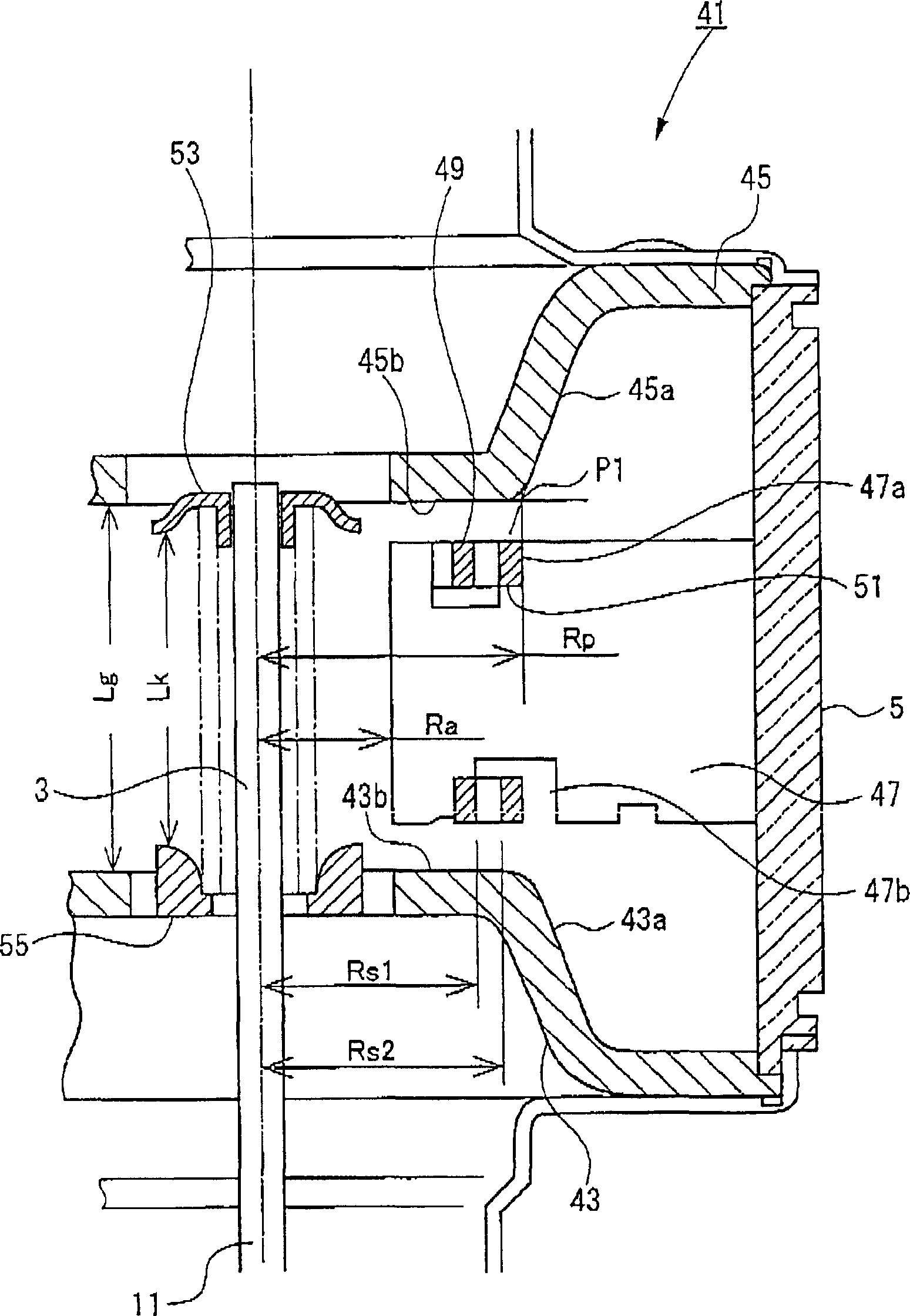

[0045] attached figure 1 is a longitudinal sectional view showing a magnetron according to an embodiment of the present invention.

[0046] According to the embodiment of the present invention, the magnetron 41 and the attached Figure 8 and 9 The conventional magnetron 1 shown has the same structure, except that input pole piece 7 is replaced by input pole piece 41, output pole piece 13 is replaced by output pole piece 45, anode vane 20 is replaced by anode vane 47, and anode vane 20 is replaced by anode vane 47. The pressure ring 49 replaces the small-diameter pressure equalizing ring 22 , and the large-diameter pressure equalizing ring 51 replaces the large-diameter pressure equalizing ring 24 . In this embodiment, the same elements as those of the conventional magnetron have the same reference numerals, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com