Plasticity forming technique regulation obtaining method based on simulation and fuzzy coarse central algorithm

A fuzzy rough set, plastic forming technology, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of insufficient development and utilization of result data, difficulty in obtaining process rules, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

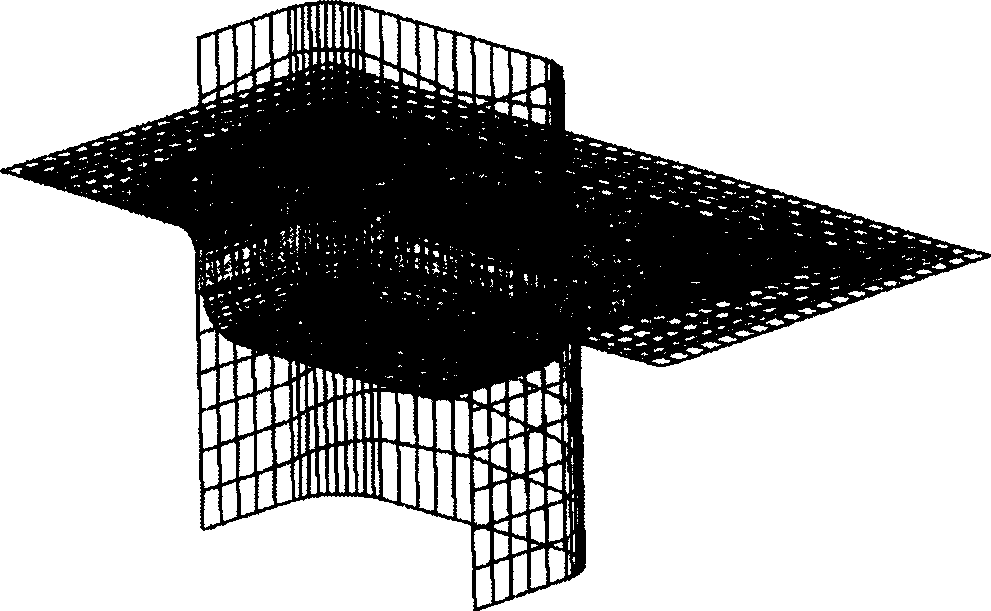

[0026] The deep drawing of square box-shaped parts is a representative plastic processing process. The invention is based on figure 1 The box-shaped part shown is drawn as an example. The sheet material is AKDQ steel plate, and the die is composed of a punch, a die, and a blank holder. Drawing beads of equal length and depth are arranged on the four sides of the blank holder. The important process parameters considered in this embodiment include the blank holder force, the friction coefficient between the sheet material and the tool, the distance of the drawbead from the centerline, the length of the drawbead, and the depth of the drawbead. The specific implementation steps of the present invention are as follows:

[0027] 1. Numerical simulation modeling and calculation of plastic forming process

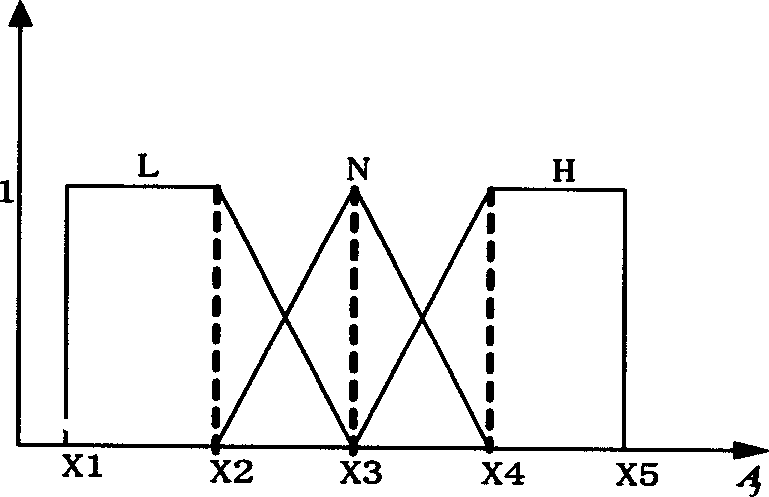

[0028] The blank holder force, the friction coefficient, the distance of the drawbead from the center line, the length of the drawbead and the depth of the drawbead are used as condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com