Heat metering method for open-ring central heating system

A heating system and measurement method technology, applied in the direction of measuring heat, calorimeters, measuring devices, etc., can solve the problems that the measurement method of the heat distribution table of the heating structure cannot be stably and accurately measured, and the measurement method of the heat meter cannot be applied, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

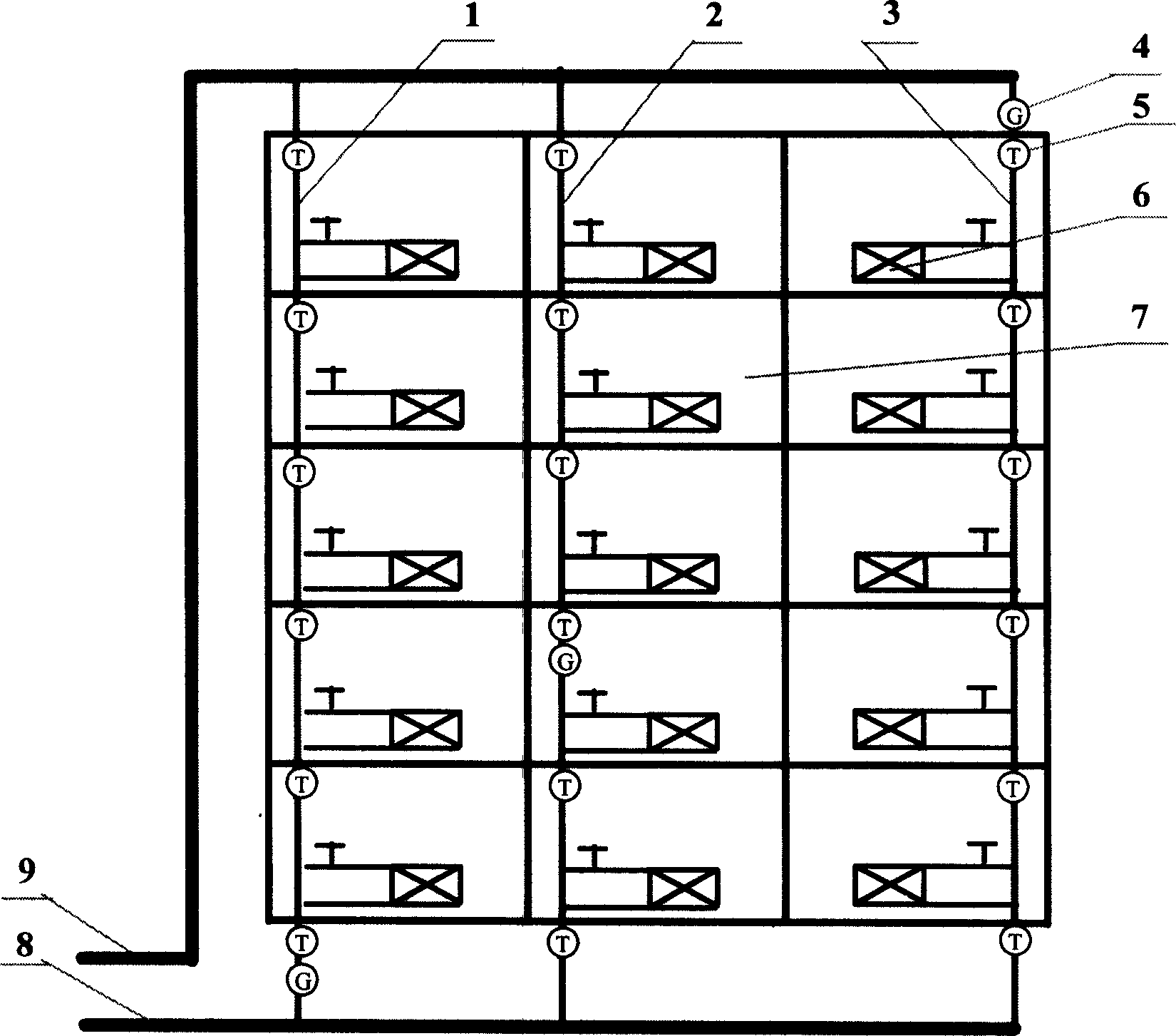

[0018] now attached figure 1 The present invention is further described:

[0019] This embodiment is a thermal measurement method for an open-loop pipeline heating structure.

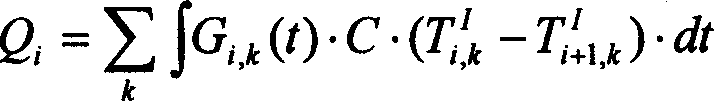

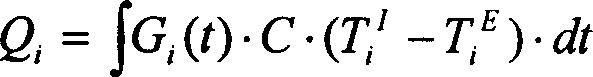

[0020] This embodiment is a five-story building with an open-loop pipeline heating structure, which adopts the upper-supply and lower-return heating method, that is, the water supply pipe 9 is laid on the upper floor, the return water pipe 8 is laid on the downstairs, and the water supply riser and the water supply pipe 9 Connected with the return pipe 8, the water flow direction in the water supply riser is from top to bottom, and each water supply riser runs through every floor of the household. Present embodiment is by five users 7 (these five users live on one floor to five floors respectively), each user has three rooms in which three heating radiators 6 are arranged, and each user room has passed through three water supply vertical pipes respectively. 1, 2 and 3 heating metering areas. Among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com