Cam driving type four stroke engine

A technology of four-stroke engine and cam drive, which is applied in the direction of variable displacement engine, reciprocating piston engine, machine/engine, etc., and can solve the constraints of engine power, economy and emission indicators, combustion temperature and pressure reduction, internal combustion engine work Roughness and other problems, to achieve good power, maximum pressure reduction, power increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

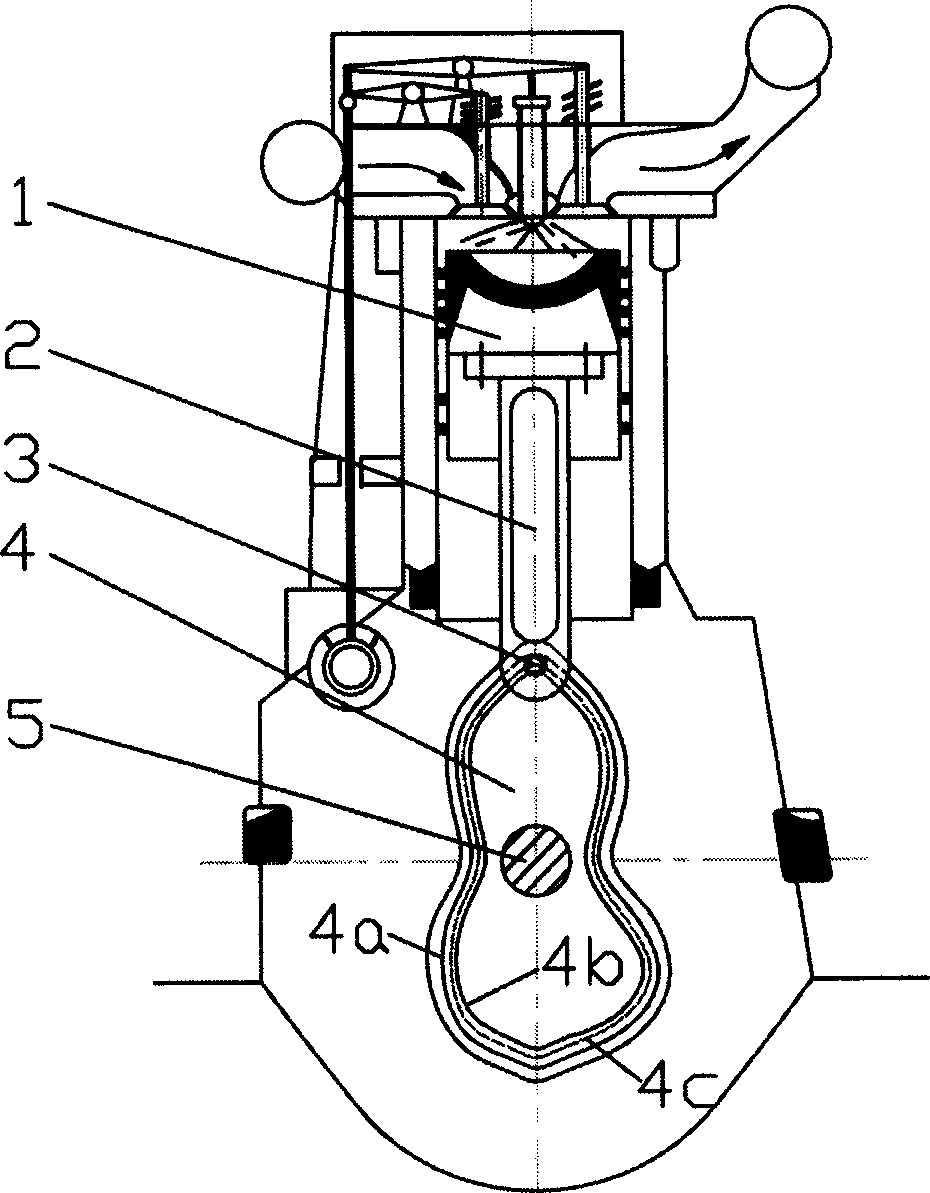

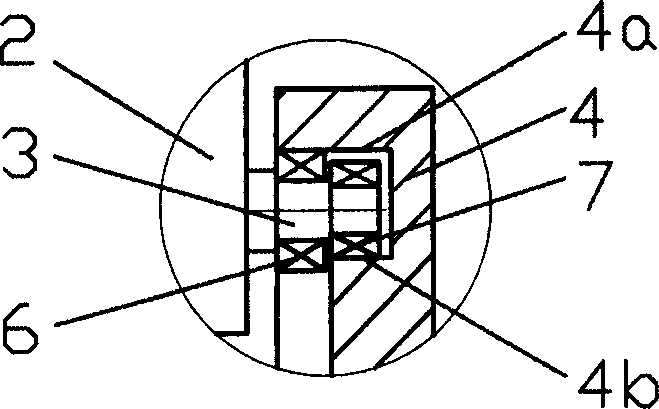

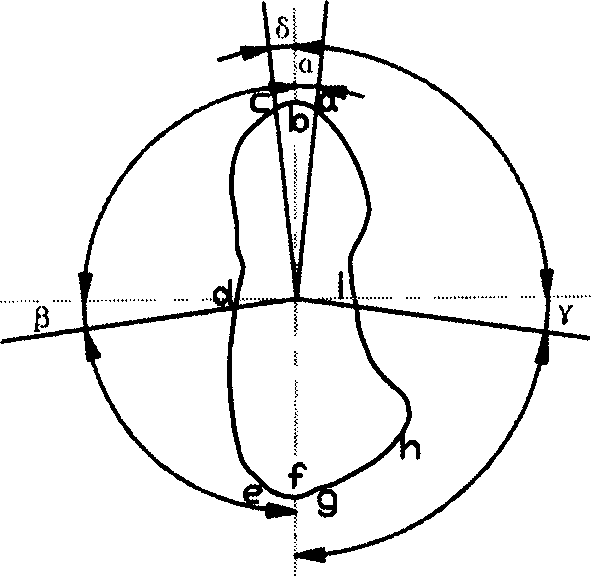

[0013] exist figure 1 , 2 In the shown embodiment, the fixed parts, valve train, fuel system, lubricating oil system, cooling system, starting system and intake and exhaust system of the cam drive type four-stroke engine are basically the same as the traditional four-stroke engine. The fixed part is composed of a machine base, a body, a cylinder head and a cylinder liner, and constitutes the skeleton of an engine. The moving part mainly includes a piston 1, a piston rod 2, an asymmetric cam 4 and a main shaft 5, the piston 1 and the piston rod 2 are connected together with fastening bolts, and the asymmetric cam 4 is fixed on the main shaft 5. The asymmetric cam 4 is provided with an asymmetric cam groove 4c, the outer edge of the asymmetric cam groove 4c is an asymmetric inner cam 4a, and the inner edge is an asymmetric outer cam 4b; The column 3 is inserted in the asymmetric cam groove 4c; the pin 3 is equipped with needle bearings 6, 7, the needle bearing 6 is in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com