Self-supported nitride semiconductor substrate and its production method, and light-emitting nitride semiconductor device using it

A technology of nitride semiconductors and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, chemical instruments and methods, etc., can solve problems such as the orientation deviation of nitride semiconductor crystals, and achieve the effect of improving characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

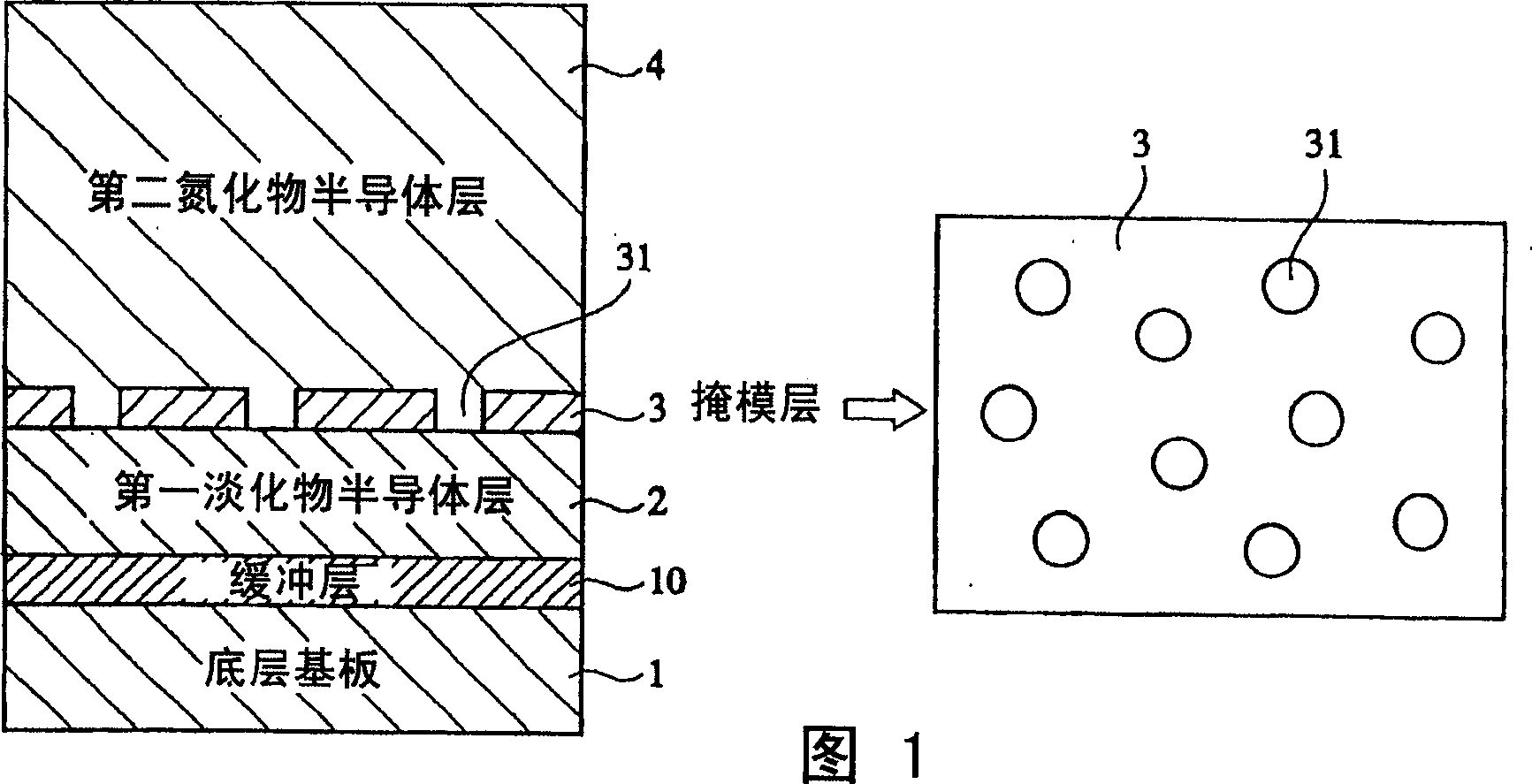

Method used

Image

Examples

Embodiment

[0035] The present invention will be further specifically described based on the following examples, but the present invention is not limited thereto.

reference example 1

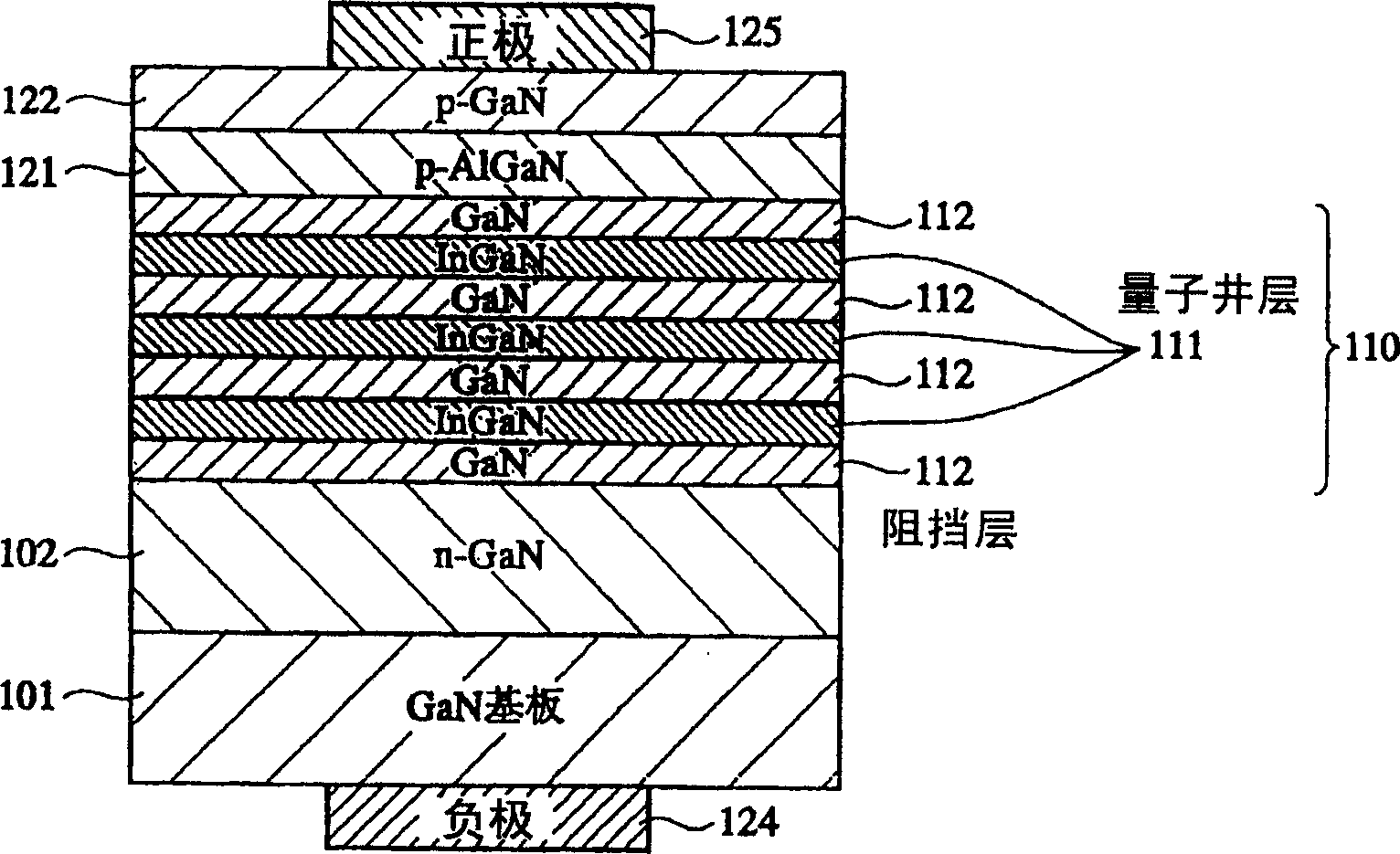

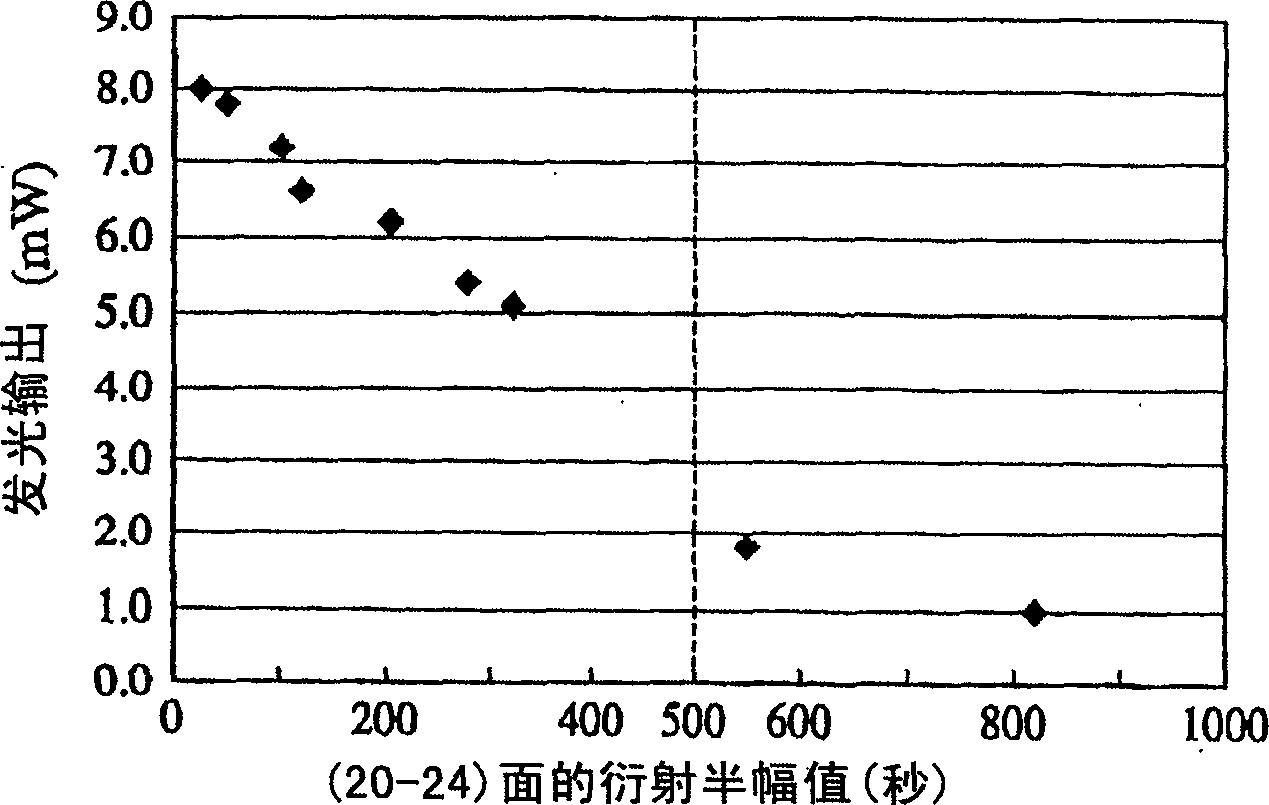

[0037] Even GaN substrates with a small X-ray diffraction half-amplitude on {0002} symmetrical diffraction planes have low luminous luminance of light-emitting diodes (LEDs) using them. substrate formation figure 2 LEDs shown.

[0038] The manufacturing method of the GaN self-supporting substrate of each sample is as follows. After forming a GaN buffer layer and a GaN layer on a 2-inch-diameter sapphire substrate, the sapphire substrate and GaN buffer layer were removed. Both surfaces of the obtained GaN substrate were polished to produce a GaN self-supporting substrate with a thickness of 270 μm. Manufacturing conditions such as heating temperature were changed for each sample to form a GaN buffer layer and a GaN layer.

[0039] The structure of the LED formed on each GaN self-supporting substrate is the same as in Example 8 below. Table 1 shows the relationship between the X-ray diffraction half-width of the {0002} plane of the GaN self-supporting substrates of Samples 1...

Embodiment 1

[0042] In the tubular reaction vessel made of quartz provided with a halogen gas supply pipe and a N source supply pipe, a quartz boat containing Ga metal is provided at a position close to the halogen gas supply pipe, and at a position away from the quartz boat and close to For the position of the N source supply pipe, the sapphire base substrate 1 with a diameter of 2 inches perpendicular to the reaction pipe is fixedly arranged on the support.

[0043] While heating the quartz boat containing Ga metal to 900°C, heat the sapphire base substrate 1 to 510°C. In this state, the carrier gas hydrogen and HCl gas are introduced into the tubular reaction vessel from the halogen gas tube, and the tube is supplied from the N source. Supply nitrogen and ammonia as carrier gases. HCl gas reacts with Ga to form GaCl. According to GaCl and NH 3 reaction, a buffer layer made of GaN was grown with a film thickness of 30 nm on the sapphire underlying substrate 1 .

[0044] The temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com