Optical fiber sensitive element metallized packaging structure and its method

A technology of sensitive components and packaging structures, applied in the direction of electrical components, coupling of optical waveguides, electromagnetic wave transmission systems, etc., can solve the problems of affecting the linearity and repeatability of measurement, easy aging and decomposition, unfavorable long-term use, etc., to avoid aging and redundancy, good linearity and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

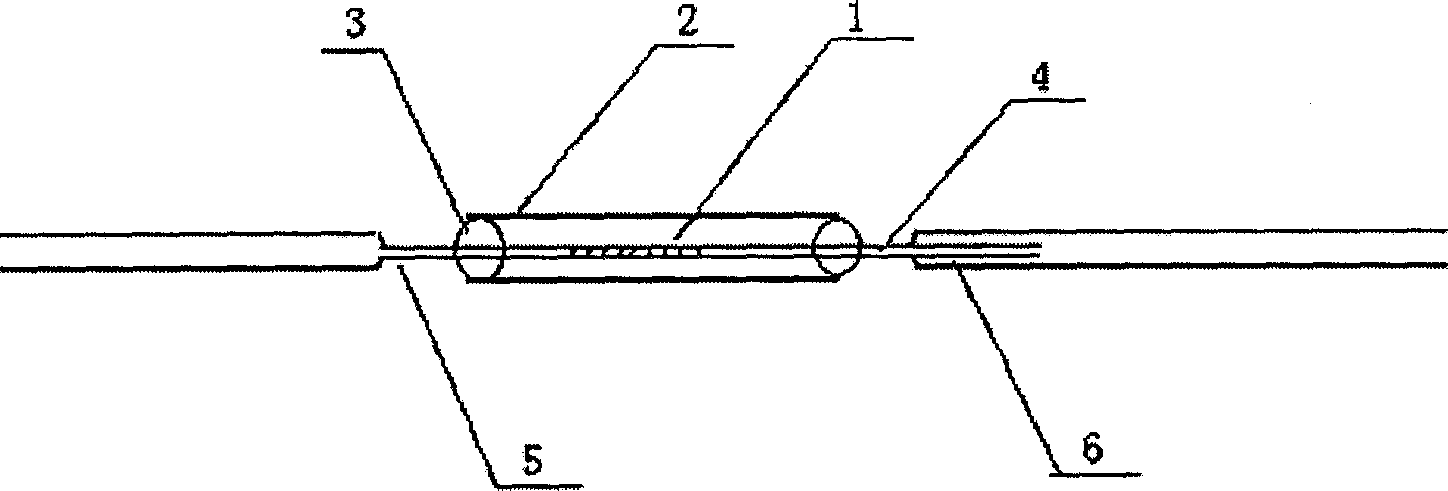

[0012] Such as figure 1 As shown in ., the present invention is a metallized packaging structure for optical fiber sensitive components, mainly comprising optical fiber sensitive components (1), metal tubes or metal sheets (2), characterized in that the surface of the optical fiber sensitive components has a metal coating (5), and There are metal welding spots (3) to weld the optical fiber sensitive element (1) and the metal pipe or metal sheet (2).

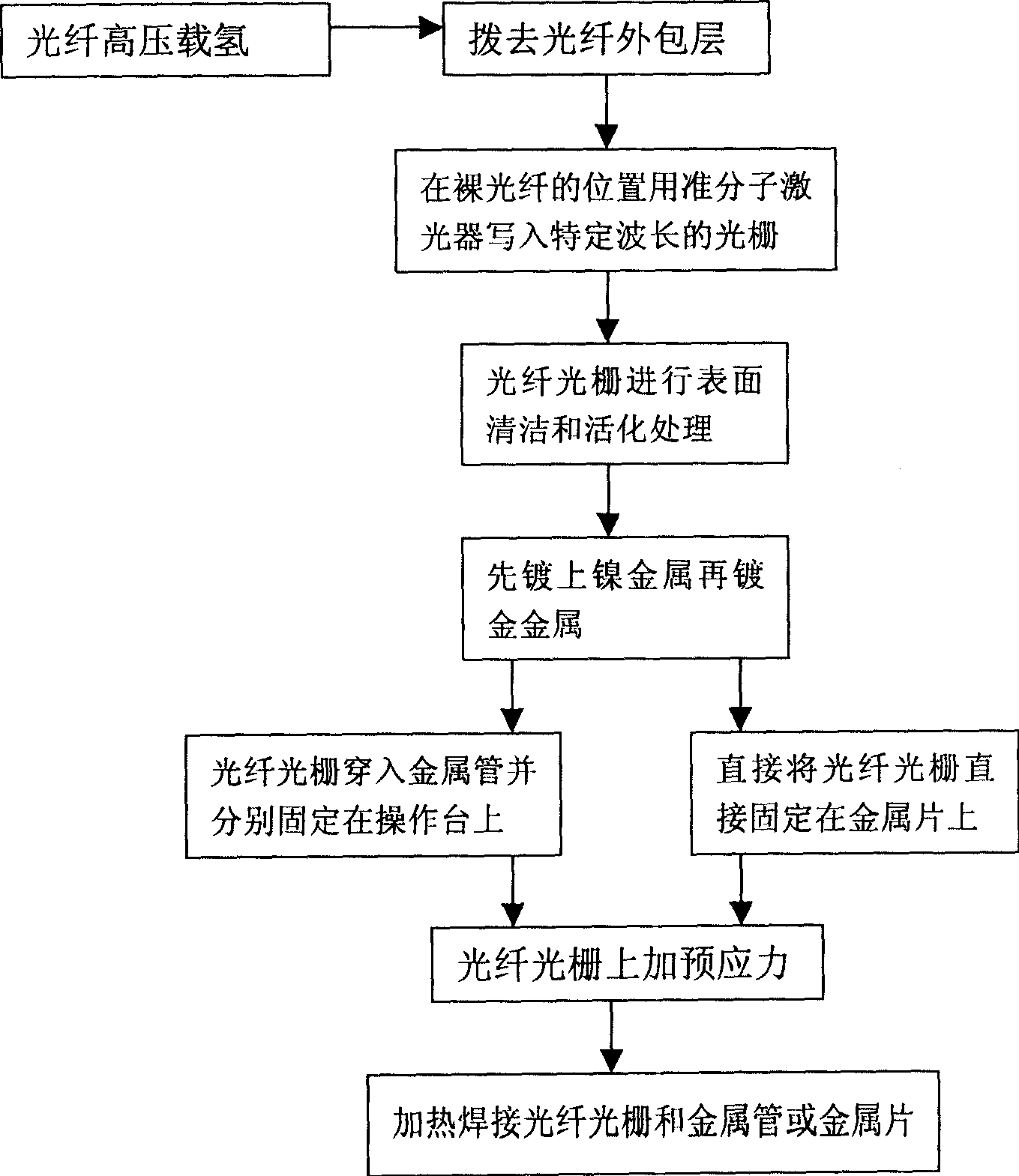

[0013] Its implementation steps are as follows figure 2 It shows that the outer cladding (6) of the hydrogen-carrying optical fiber is removed, and a grating (1) of a specific wavelength is written in the position of the bare optical fiber (4) with an excimer laser.

[0014] Degreasing: Wipe the surface of the fiber several times with an alcohol cotton ball, and then use less than 100gL -1 Soak in NaOH solution for 10 minutes, take it out and rinse thoroughly with deionized water.

[0015] Coarsening: with F - or H 2 SiF 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com