Multiple group layer combustion-supporting gas making screen device for coal-turned-gas boiler

A coal-to-gas and boiler technology, which is applied to combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of affecting the calorific value effect of the boiler, poor coal seam combustion, and poor grate air supply, etc., so as to increase the available energy, Huge economic and social benefits, the effect of reducing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

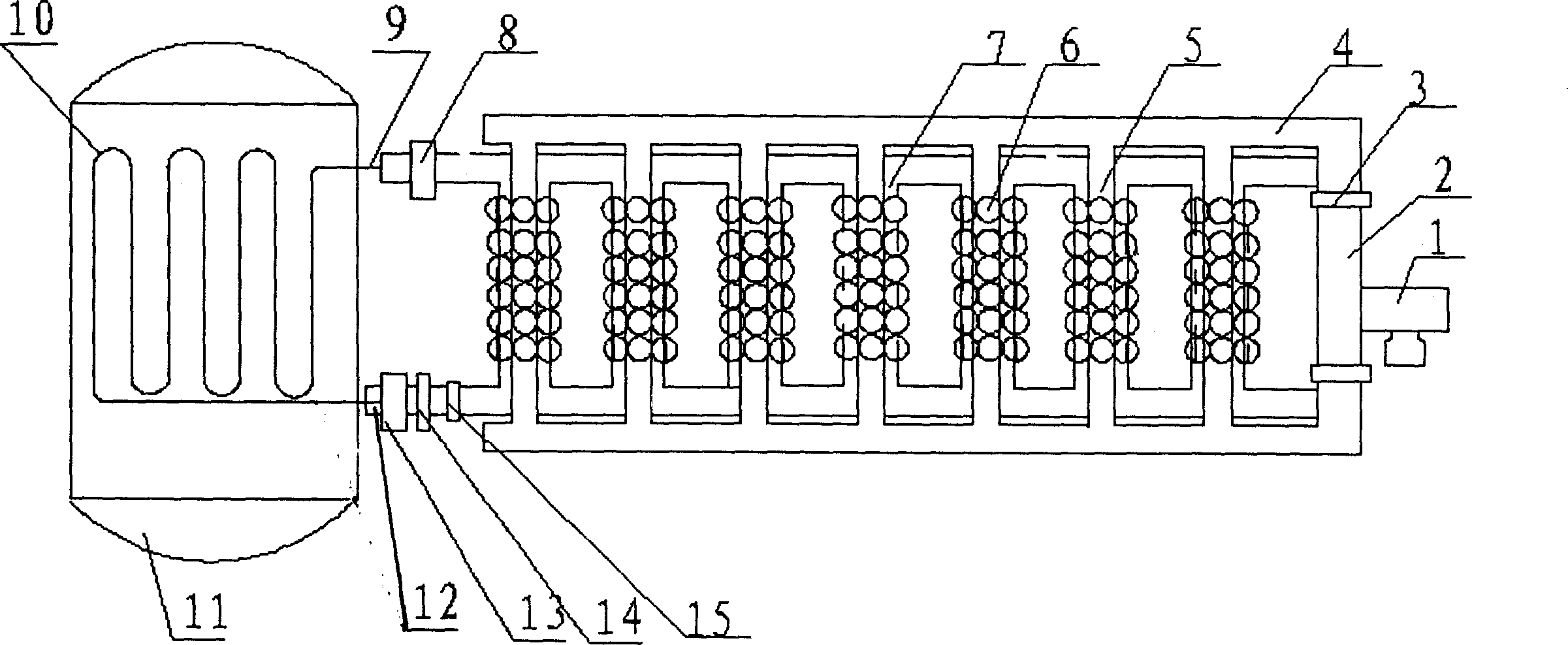

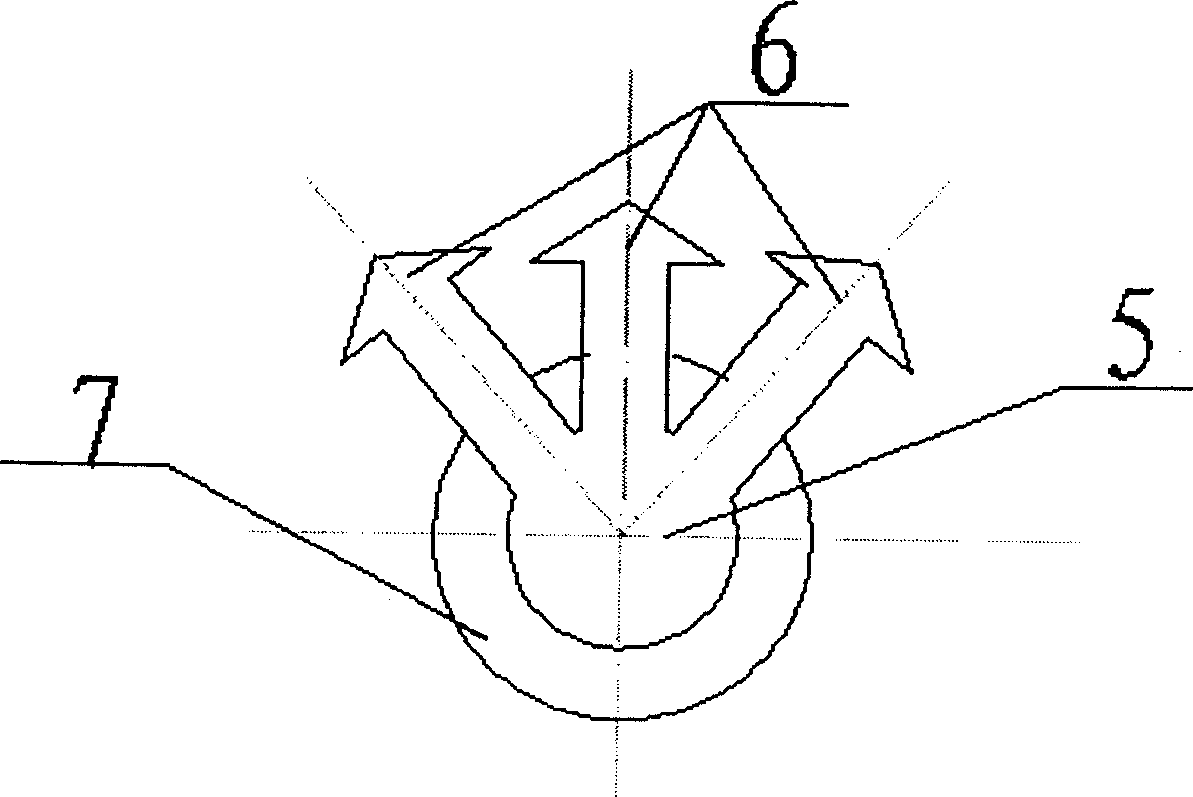

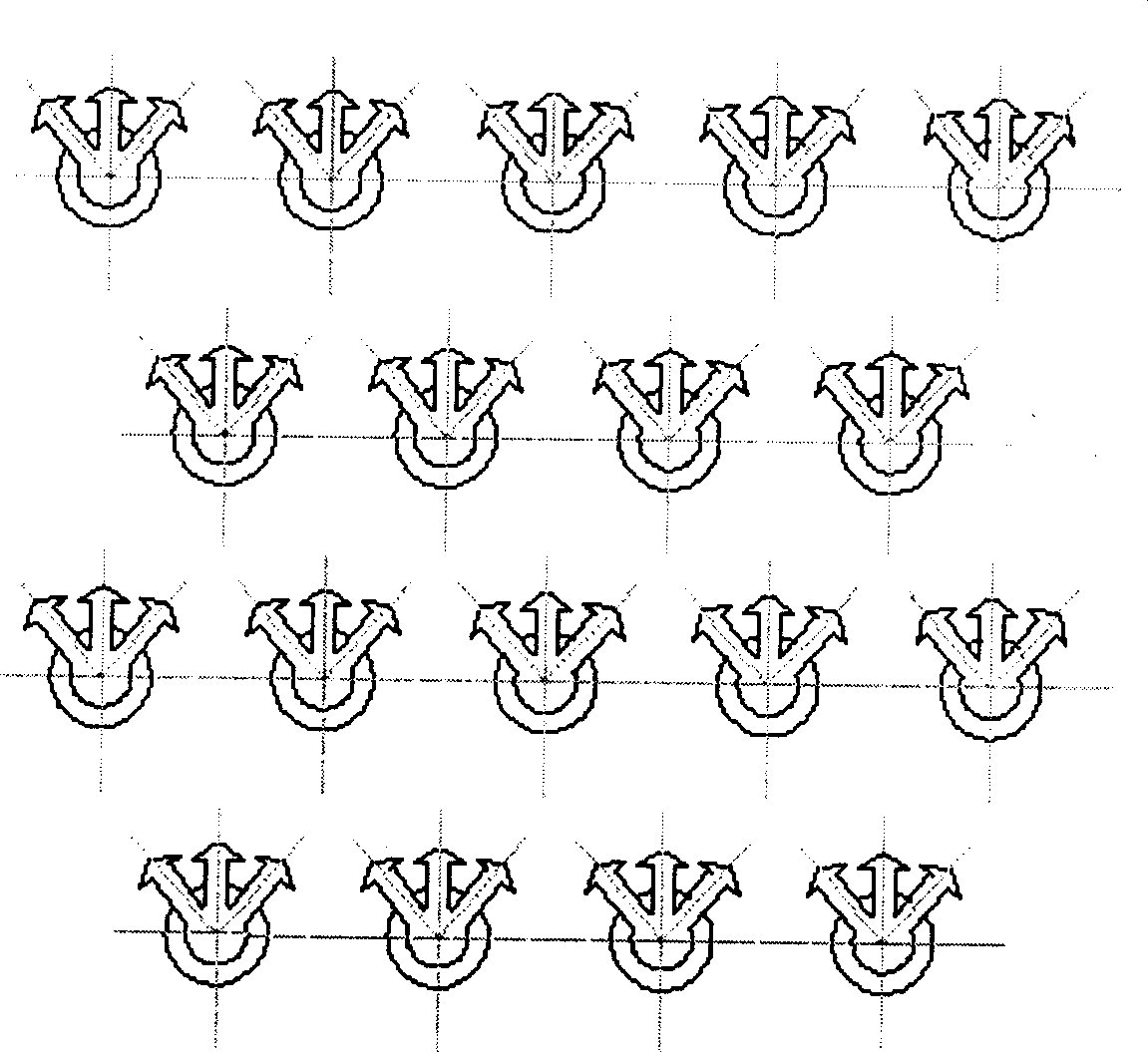

[0009] A group of layer structures of the present invention are in accordance with figure 1 The implementation of the structure shown, the multi-layer combustion-supporting gas pipe panel device, the installation between the upper and lower layers, and the arrangement of the air, gas and oil pipelines are as follows: image 3 For the installation of the structure shown, the installation of each group (row) of air and oil pipe screens can be installed on the shoulder specially built on the inner wall of the furnace hall. The number of pipe screens on each layer can be selected according to the size of the furnace hall, or Choose high-temperature-resistant materials, such as high-temperature-resistant steel, and design multi-layer support frames according to the shape of the furnace hall to install multi-layer combustion-supporting gas pipe screens. Among them, the blower air intake device 1 adopts a frequency conversion blower, and the specifications are selected according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com