Method for replacing and resetting imperfect multi-piece printed circuit board

A printed circuit board and multi-chip technology, which is applied in the fields of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problem of bad multi-chip printed circuit board replacement reset cutting limit and error value, bad multi-chip printed circuit Problems such as board replacement and replacement can be solved to achieve the effect of strengthening market competitiveness, reducing waste disposal problems, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

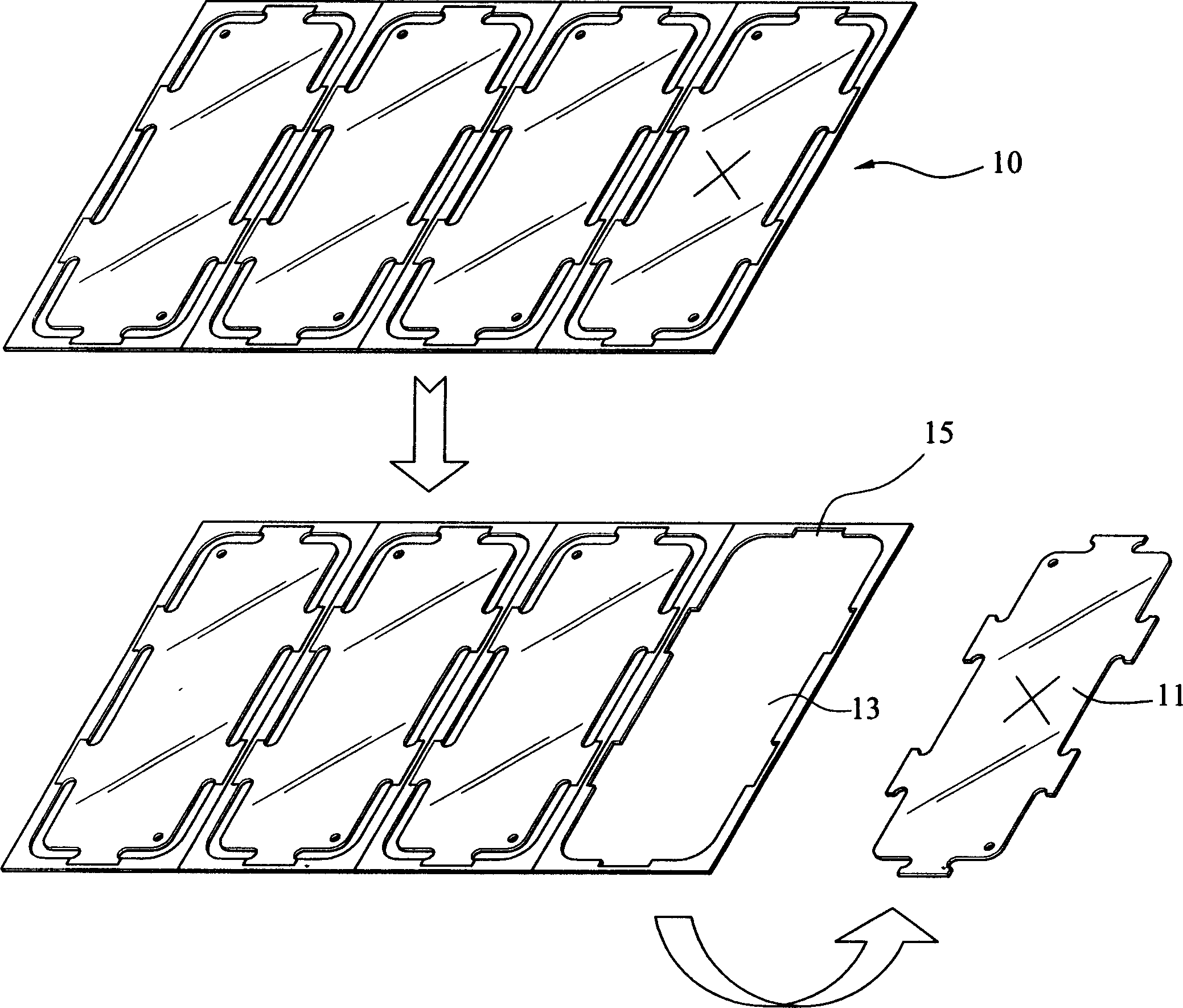

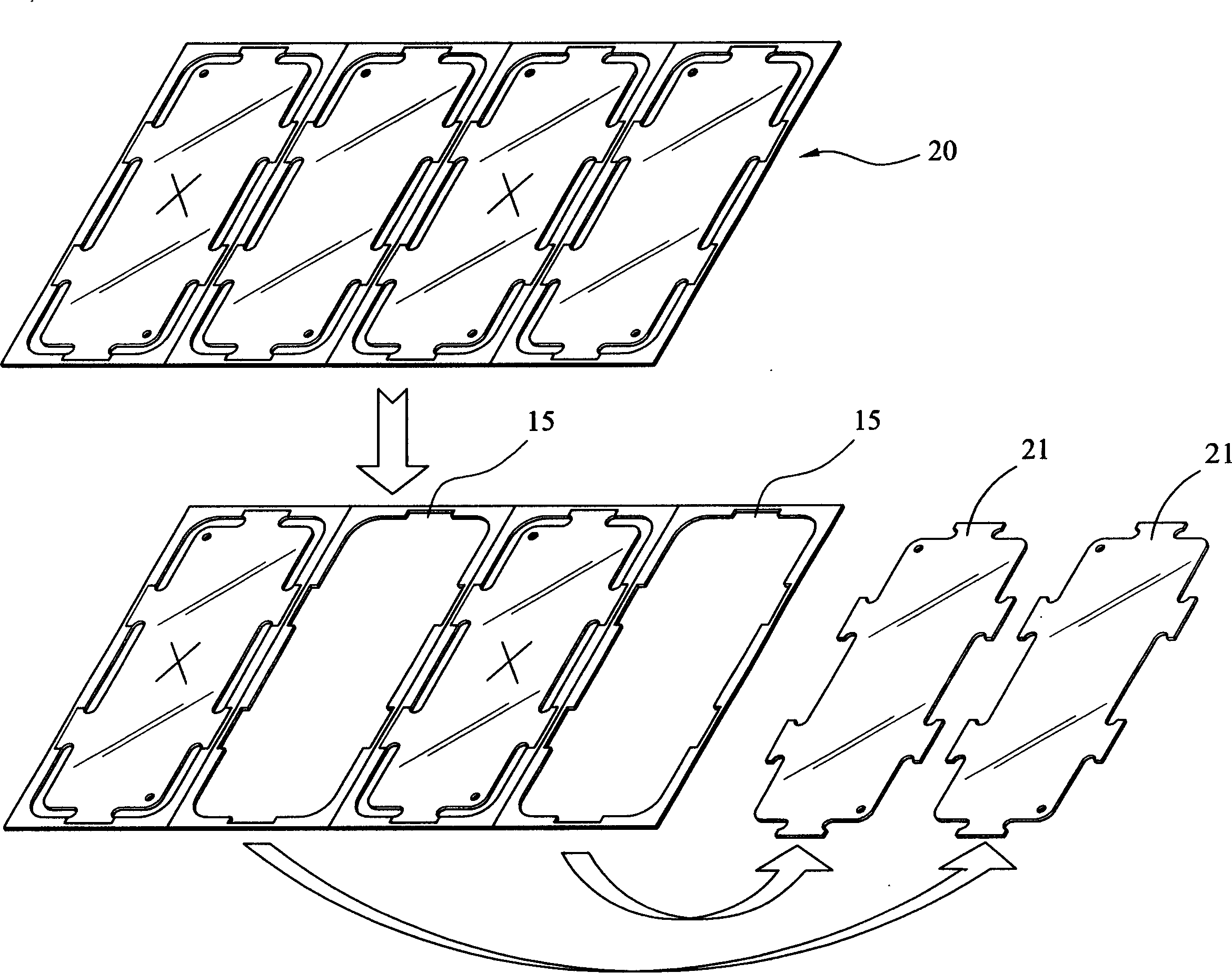

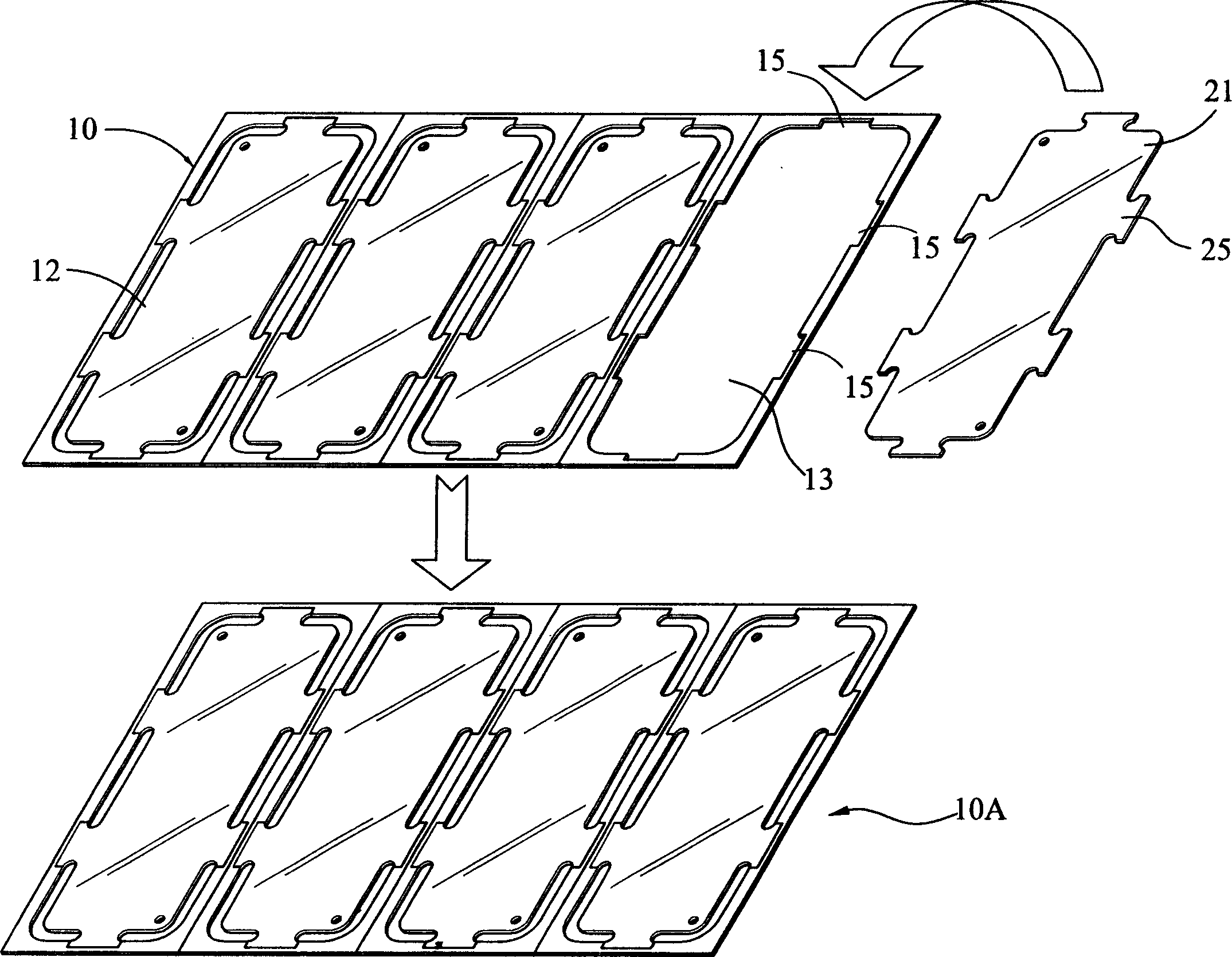

[0034]Please refer to Figures 1 to 3, the method for replacing and resetting defective multi-connected printed circuit boards of the present invention is first to cut the defective single-chip (printed circuit board) 11 in a defective multi-connected sheet (printed circuit board) 10 Remove, and then use the same method to cut out the good product single piece (printed circuit board) 21 in another bad multi-piece 20, and its cutting operation is carried out with precision cutting tools such as laser, CNC; and the removal The defective multi-unit sheet 10 of the defective single-piece 11 is left with a good product single-piece 12 and a missing portion 13, and then the removed good-quality single-piece 21 is filled into the missing portion 13 of the defective multi-unit piece 10, as shown in FIG. 3 As shown, after precise positioning by means of template positioning, optical positioning or computer positioning, etc., use printing, automatic, manual and other glue injection method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com