Treating structure for sling rope weaving and inserting terminal

A sling and weaving technology, which is used in the bundling of ends, load hanging elements, textiles and papermaking, etc., can solve the problems of thin thickness, damage, wear or bumps of heat shrinkable sleeves, and reduce operation time. , The effect of improving durability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the processing structure of the end portion of the sling weaving according to the present invention will be described with reference to the drawings.

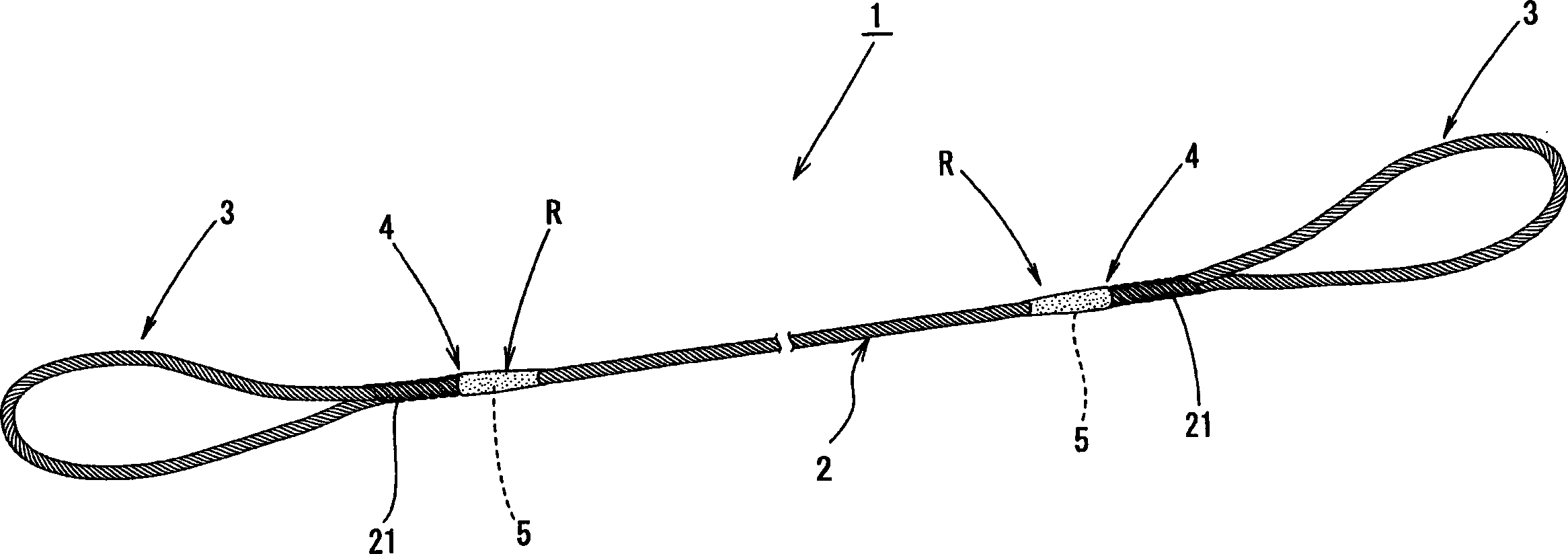

[0026] figure 1 It is a three-dimensional view of the sling, and the symbol 1 in the figure represents the whole sling.

[0027] In this sling 1 , twisted collars 3 and 3 are formed at both end portions of a wire rope 2 to be hung on a hook of a crane, an elevator, or the like.

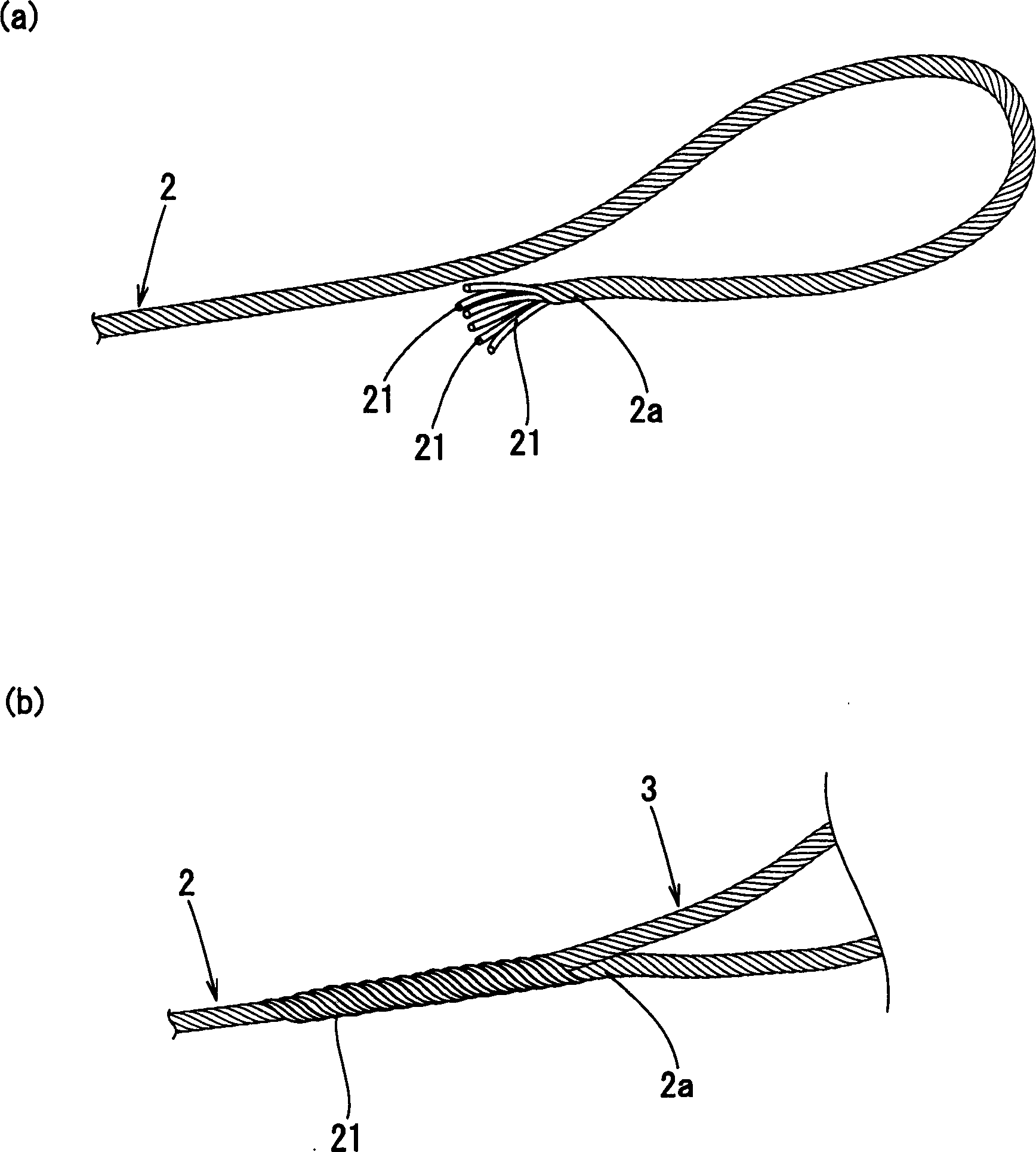

[0028] The above-mentioned steel cable 2, whose detailed illustration is omitted, is a steel cable of a well-known structure formed by twisting a plurality of steel wires into strands 21, and then intertwisting the strands 21.

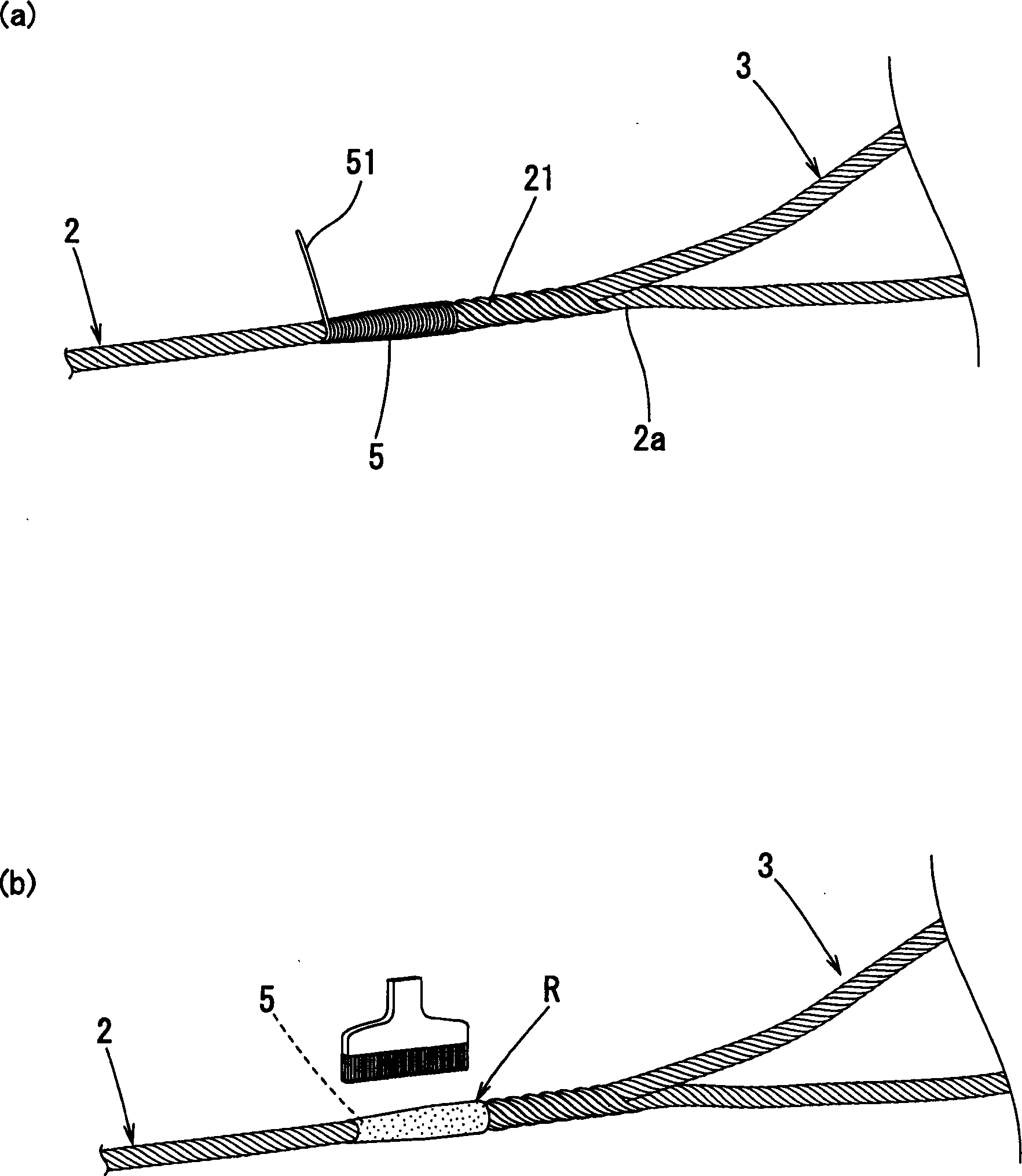

[0029] The above-mentioned twisted collars 3, 3 are formed by bending the front end portion 2a of the steel cable 2 and braiding and inserting the end portion thereof into the steel cable 2, and at the same time weaving the rolled-back protective wire 5 around the outer circumferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com