Gas distributor in fluidized bed of aniline synthesis and aniline synthesis method

A technology of gas distributor and synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as unavoidable large temperature rise, affecting the purity of aniline products, and carbon deposition activity of catalysts, and achieves Good gas-solid contact effect, guaranteed gas-solid contact effect, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

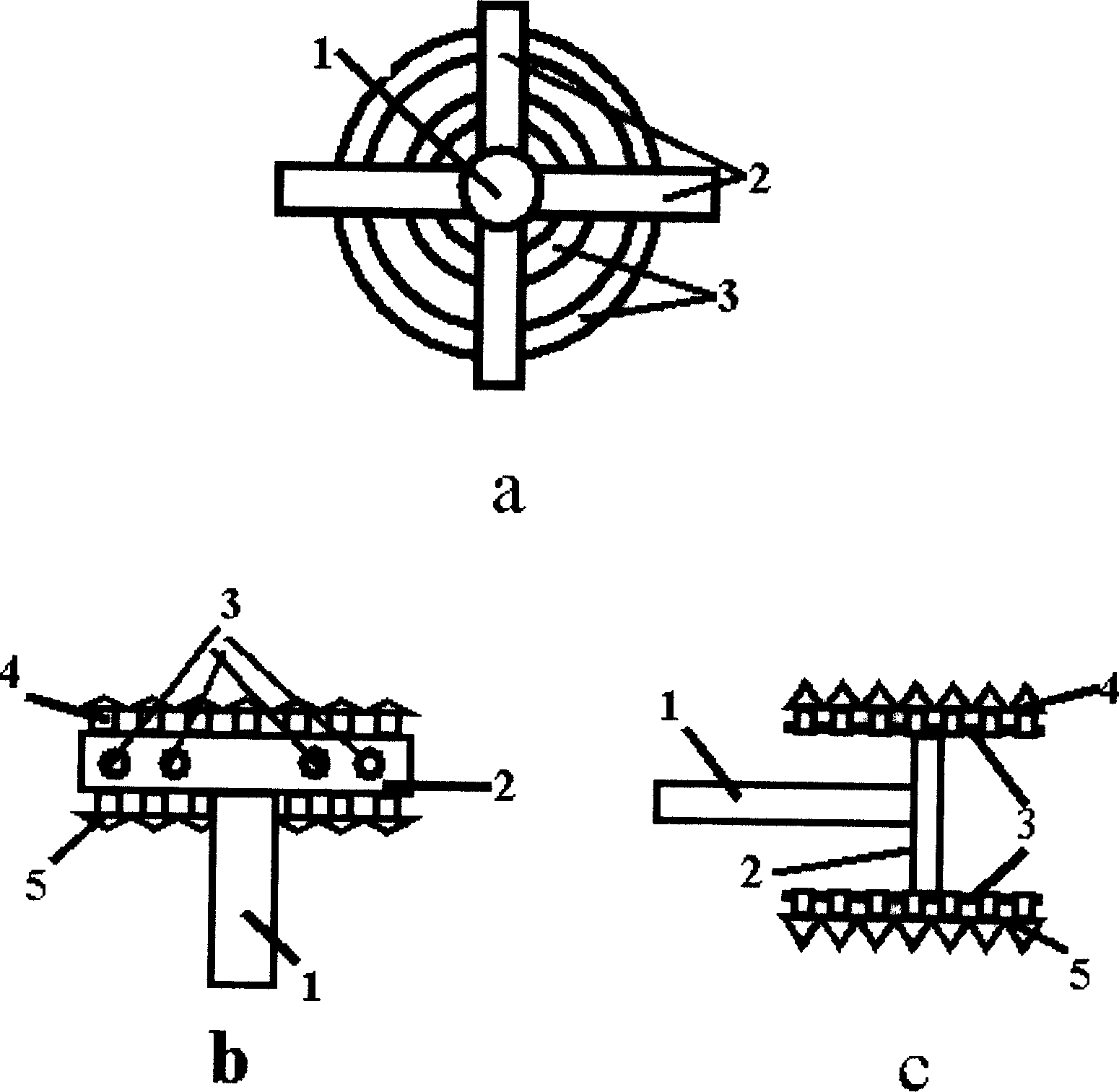

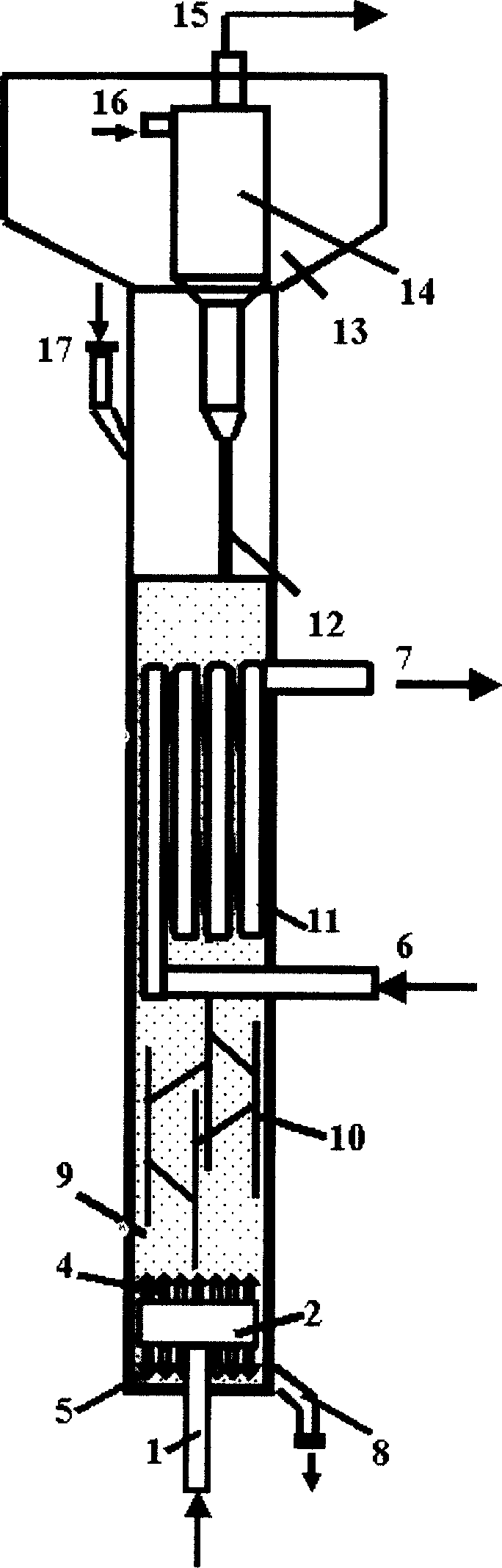

[0035] in such as figure 2 The reaction is carried out in the fluidized bed apparatus shown for the preparation of aniline by gas-phase hydrogenation of nitrobenzene. Set an annular pipeline for distributing gas, whose diameter is 90% of the diameter of the main air pipe; control the ratio of the number of upward nozzles on the distributor to the number of downward nozzles to be 1:1, and the installation distance between the outlet of the downward nozzle and the outlet of the upward nozzle is 200mm. The gas velocity in the main intake pipe is 5m / s, and the gas velocity at the nozzle outlet is 100m / s. The feed is hydrogen and nitrobenzene, the molar ratio is 20:1; the operating pressure (absolute pressure) is 0.25MPa; the catalyst (Cu-SiO 2 ) The average temperature in the dense phase area is 260°C, the average temperature in the gas distributor area is 265°C; the weight space velocity is 0.2 hours -1 , the actual gas velocity in the catalyst dense phase zone is 0.1m / s. In...

Embodiment 2

[0037] in such as figure 2 The reaction is carried out in the fluidized bed apparatus shown for the preparation of aniline by gas-phase hydrogenation of nitrobenzene. Set up three annular pipes for distributing gas, the diameters of which are 20%, 40%, and 60% of the diameter of the main air pipe respectively; The installation distance from the upward nozzle outlet is 500mm. The gas velocity in the main intake pipe is 20m / s, and the gas velocity at the nozzle outlet is 150m / s. Feed is hydrogen and nitrobenzene, and molar ratio is 7: 1; Operating pressure (absolute pressure) is 0.1MPa; Catalyst (Cu-Al 2 o 3 ) The average temperature of the dense phase area is 255°C, the average temperature of the gas distributor area is 270°C; the weight space velocity is 0.1 hour -1 , the actual gas velocity in the catalyst dense phase zone is 0.9m / s. Within two months, the content of nitrobenzene in crude aniline was 4.5 mg / kg, and the content of cyclohexanol and cyclohexylamine were 20...

Embodiment 3

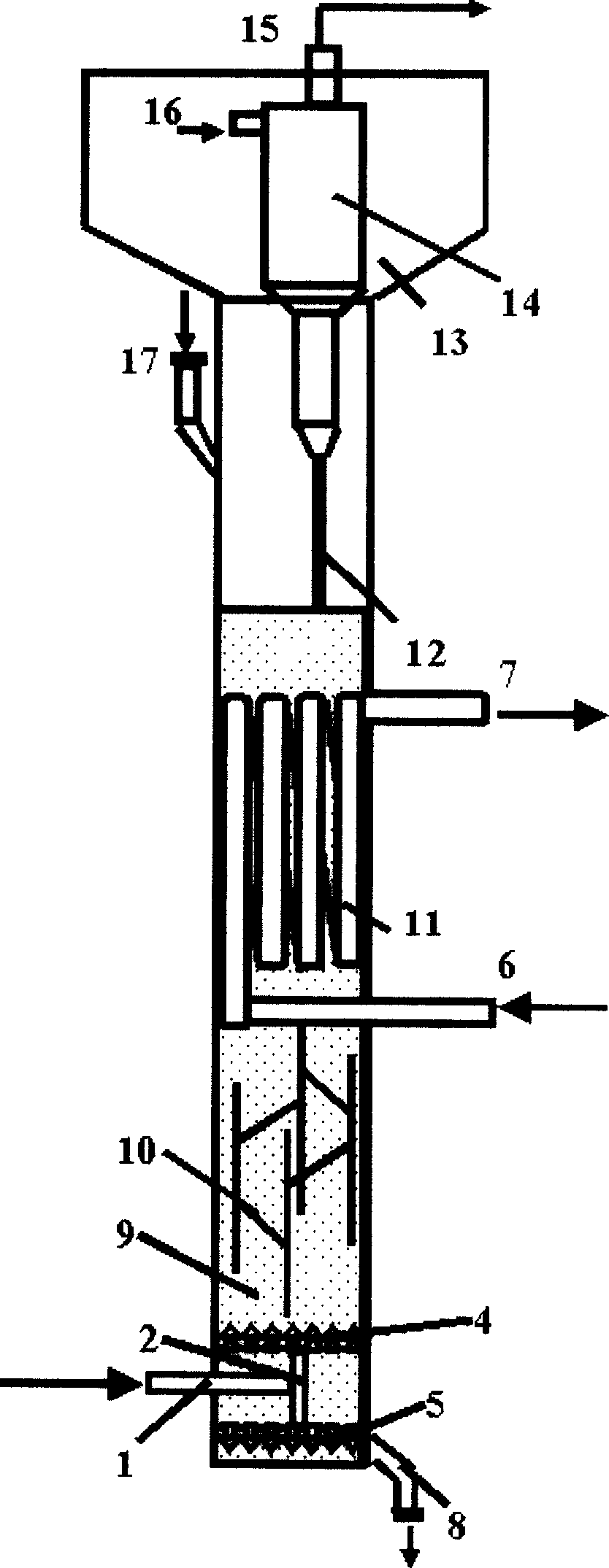

[0039] in such as image 3 The reaction is carried out in the fluidized bed apparatus shown for the preparation of aniline by gas-phase hydrogenation of nitrobenzene. Set four annular pipes for distributing gas, whose diameters are 10, 20%, 50%, and 80% of the diameter of the main air pipe; the ratio of the number of upward nozzles on the distributor to the number of downward nozzles is 1:3, and the The installation distance between the nozzle outlet and the upward nozzle outlet is 1000mm. The gas velocity in the main intake pipe is 15m / s, and the gas velocity at the nozzle outlet is 60m / s. The feed is hydrogen and nitrobenzene, and the molar ratio is 12:1; the operating pressure (absolute pressure) is 1.0 MPa; the average temperature of the catalyst dense phase zone is 250 ° C, and the average temperature of the gas distributor area is 256 ° C; Speed is 0.23 hours -1 , catalyst (Cu-Al 2 o 3 ) The actual gas velocity in the dense phase region is 0.6m / s. The content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com