Body joint replacement titanium implant comprising one or several base bodies

A technology for implants and joints, applied in the direction of joint implants, joint implants, hip joints, etc., can solve the problems of not being able to prevent fixation, and achieve the effect of improving slidability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

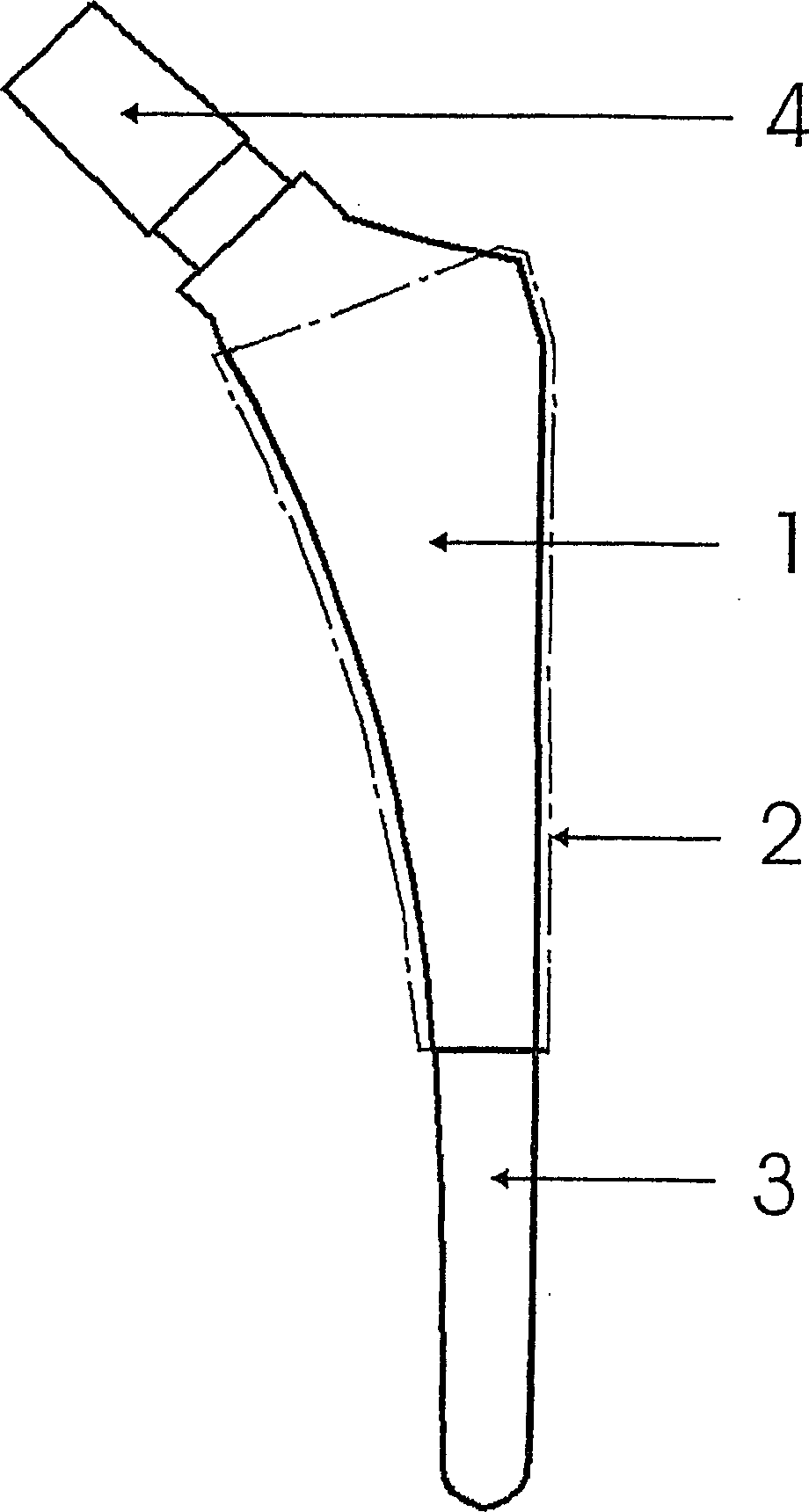

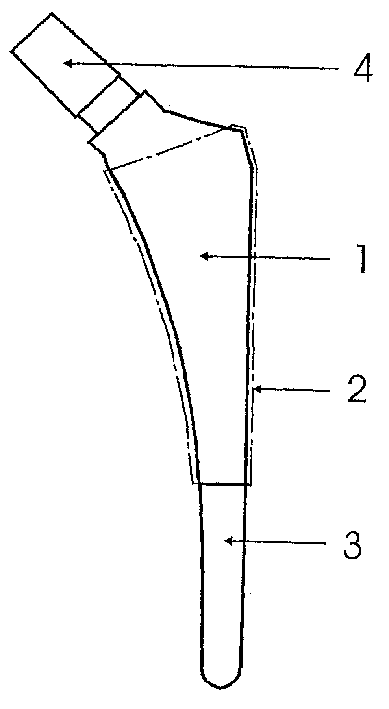

[0013] figure 1 The hip implant consists of a base body 1 with a region 2 in its proximal part, which is firmly fixed to the bone. The region preferably has a rough surface, which is formed by sandblasting with a coarse-grained material or by titanium coating. In order to stimulate bone growth, it is advantageous to coat the rough surface with one or more absorbable calcium phosphate layers. In the region of the distal end of the implant, a region 3 which is not intended to ossify and is thus anodically (type II) oxidized adjoins the aforementioned region. During the surface modification, oxygen and silicon are introduced into the titanium surface, where they form the integral constituents of the conversion layer. The region does not have TiO 2 Floor. Carbon and nitrogen can also be introduced into the conversion layer if desired.

[0014] On the one hand, the transformed layer prevents the growth of bone cells. However, the conversion layer also imparts greater hardness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com