Distributed optical fiber grating temperature detection system for high voltage electric power equipment

A technology of high-voltage power equipment and distributed optical fiber, which is applied in the field of measurement, can solve the problems of indistinguishable operation overtemperature, etc., and achieve the effects of strong anti-interference ability, large number of measurement points, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

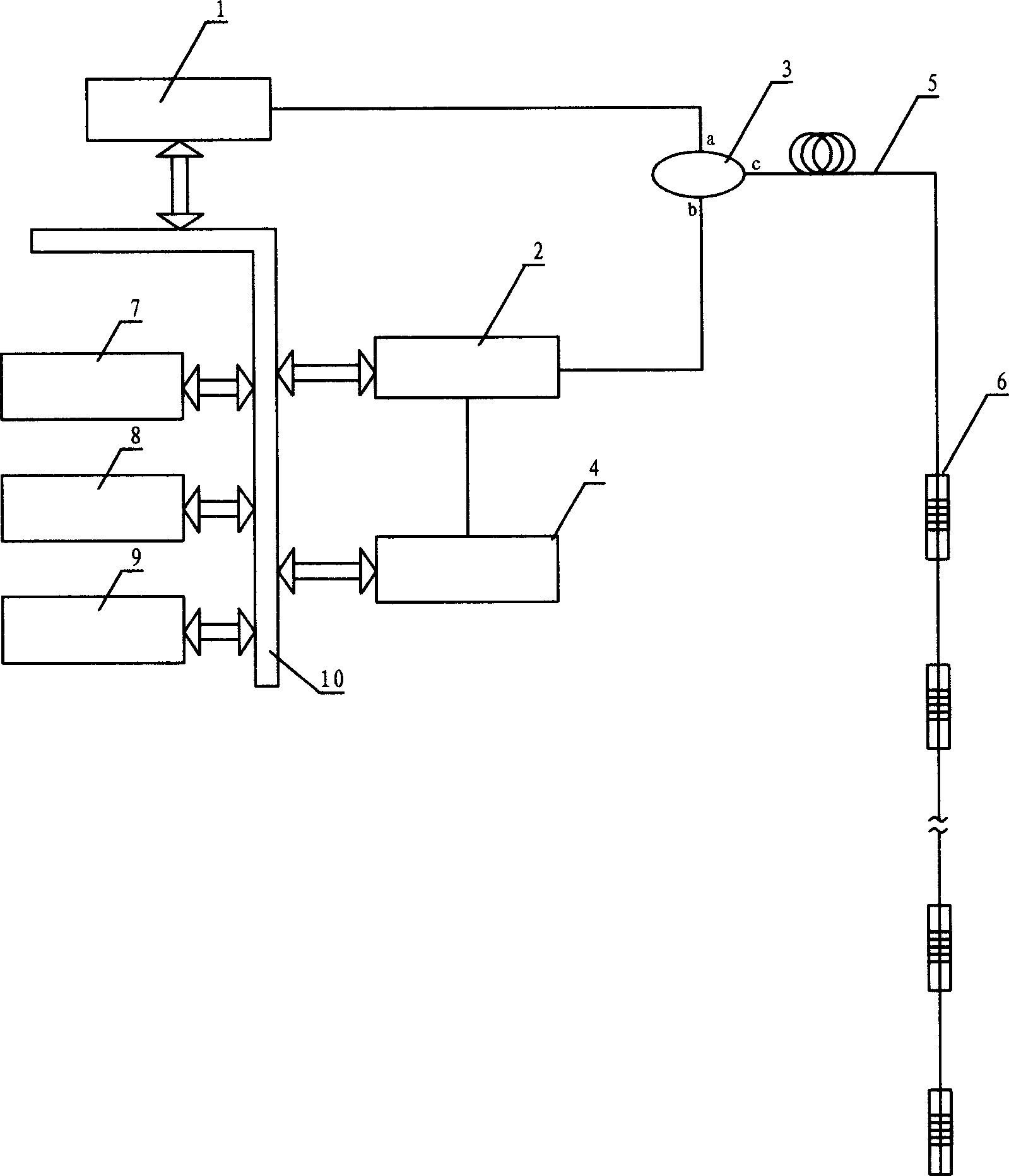

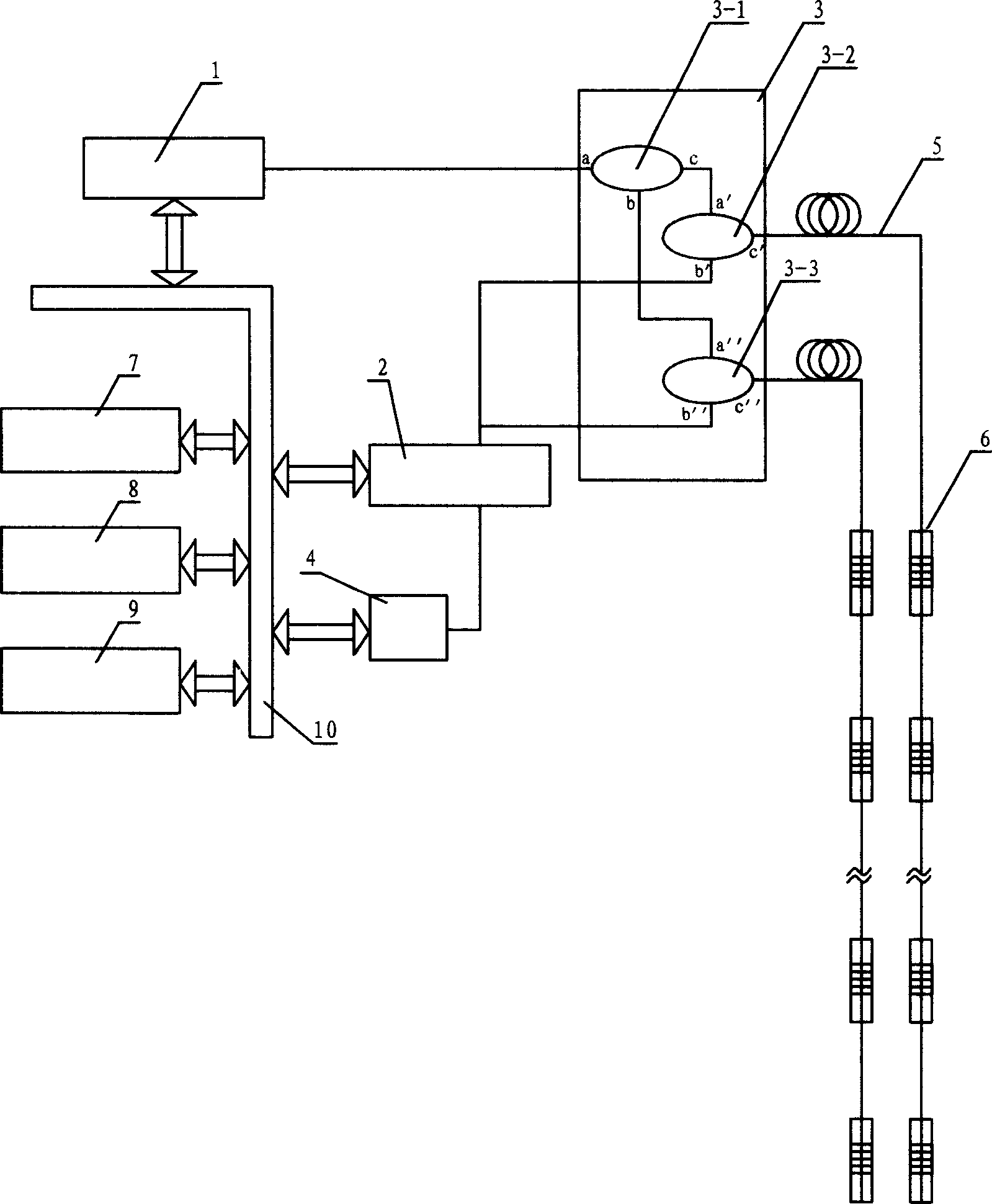

[0036] exist figure 1 The system structure shown and figure 2 The control and data processing unit shown is based on the use of image 3 In the shown optical path and circuit structure, the fiber coupler 3 includes at least three fiber couplers 3-1, 3-2 and 3-3.

[0037] A branch port a of the first fiber coupler 3-1 is optically connected to the broadband laser light source 1, and another branch port b of the first fiber coupler 3-1 is optically connected to a branch port a of the third fiber coupler 3-3. A combining port c of the fiber coupler is optically connected to a branching port a' of the second fiber coupler 3-2.

[0038] Another branch port b' of the second fiber coupler is optically connected to the input port of the photodetector module 4 through the tunable optical fiber filter 2, and its combined port c' is connected to at least two with different central wavelengths through the external optical fiber 5. The fiber grating sensors 6 are connected in series. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com