Wet method fume gas desulfurizing method and device

A flue gas and wet technology, applied in the field of flue gas desulfurization, can solve the problems of numerous supporting equipment, increased investment and operating costs of system equipment, and huge complete desulfurization system, and achieves good desulfurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

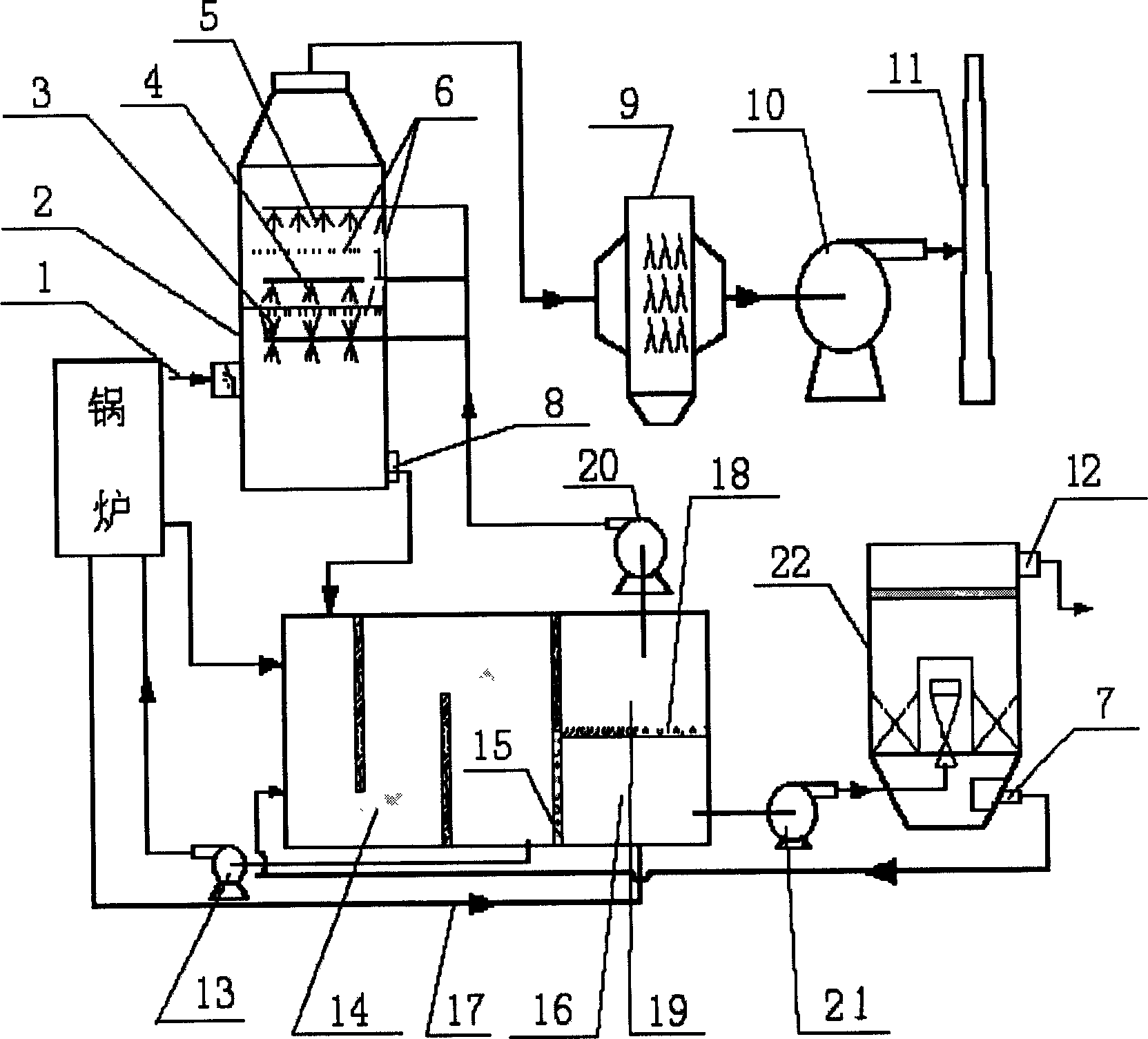

[0036] The present invention adopts the wet flue gas desulfurization method and device that the coal-fired boiler itself discharges alkaline substances, and is equipped with a boiler with an evaporation capacity of 35t / h, and the treatment flue gas volume is 100,000m 3 / h boiler flue gas.

[0037] As shown in the figure: the desulfurization method is:

[0038] 1) Dissolving the alkaline substances in the coal slag, and forming a cycle of slag washing water: the slag washing water is drawn from the rear of the alkaline substance dissolution tank 14 through the slag washing pump 13, so that the ash generated after the coal combustion in the boiler is flushed The slag water flows into the alkaline substance dissolution tank 14 together, and is mixed with the acid gray water discharged from the wet flue gas desulfurization dust collector 2. At the same time, a cycle of flushing slag water is formed;

[0039] 2) Primary filtration: the above-mentioned mixture of ash water and aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com