Manufacturing method of potishing pad use polyurethane foam and polyurethane foam

一种制造方法、聚氨酯的技术,应用在半导体/固态器件制造、研磨机床、制造工具等方向

Inactive Publication Date: 2005-06-08

ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

View PDF1 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

So, there will be disadvantages when using hollow balls to make polyurethane foam

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0052] When Adipulin L-325 is 24.1kg, foaming agent SH-192 is 0.73kg (about 3 parts), and MBOCA is 6.32kg, a block with a specific gravity of 0.845 can be obtained. In addition, the Shore D hardness was 54 at this time.

Embodiment 2

[0054] When Adiprine L-325 is 21.4kg, SH-192 is 0.81kg (about 4 parts), and MBOCA is 5.6kg, a block with a specific gravity of 0.781 can be obtained. In addition, the Shore D hardness was 51 at this time.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

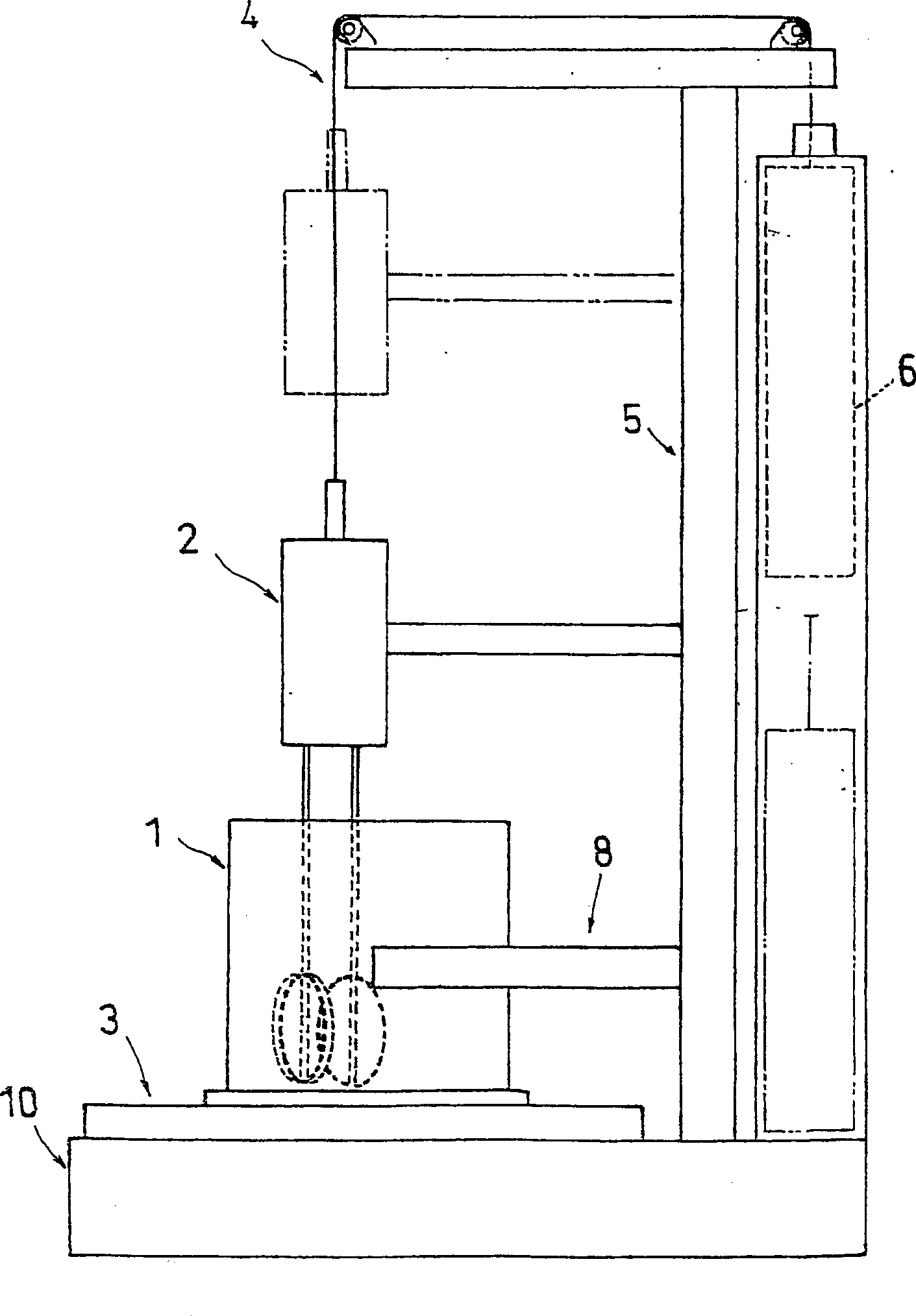

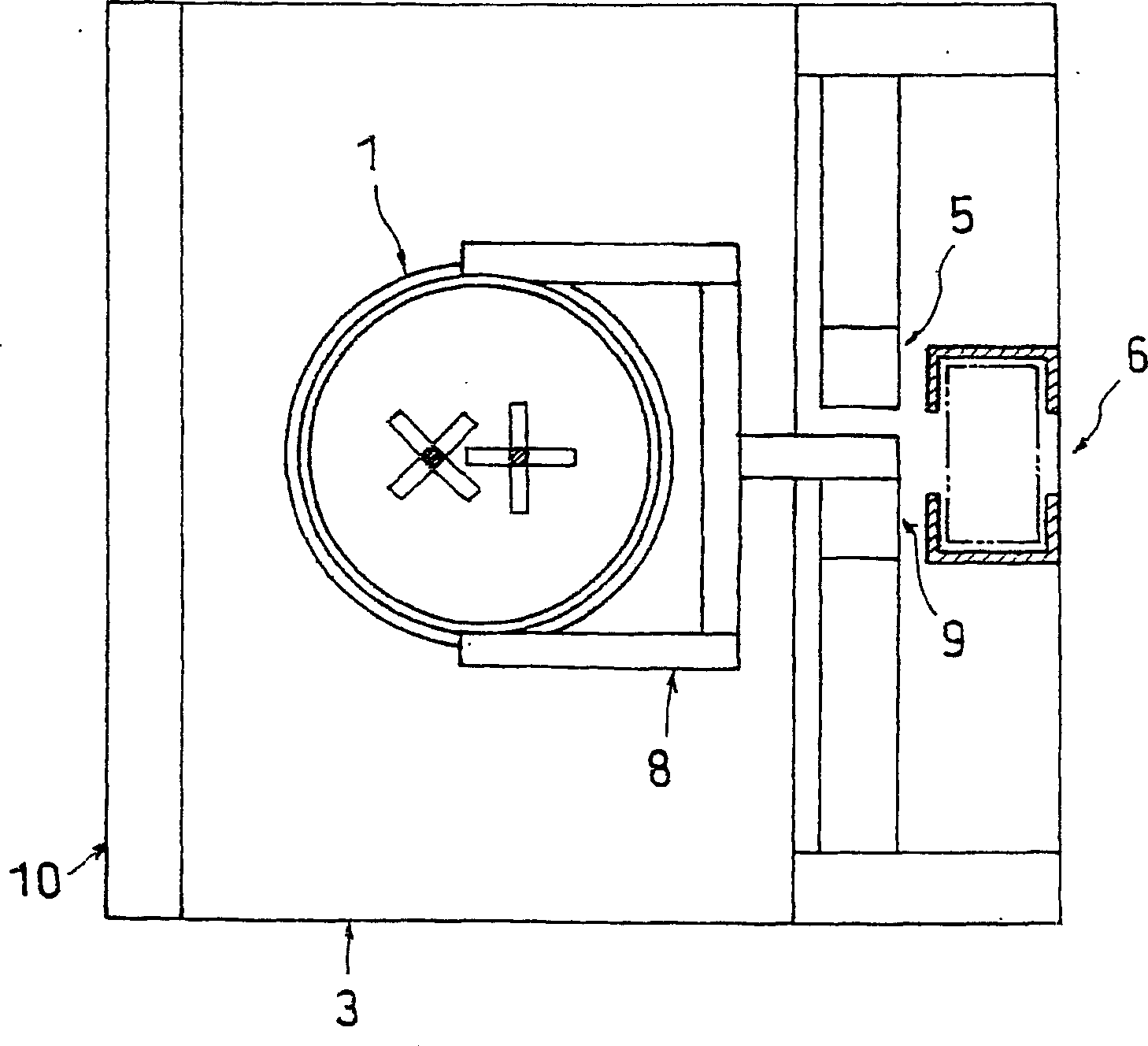

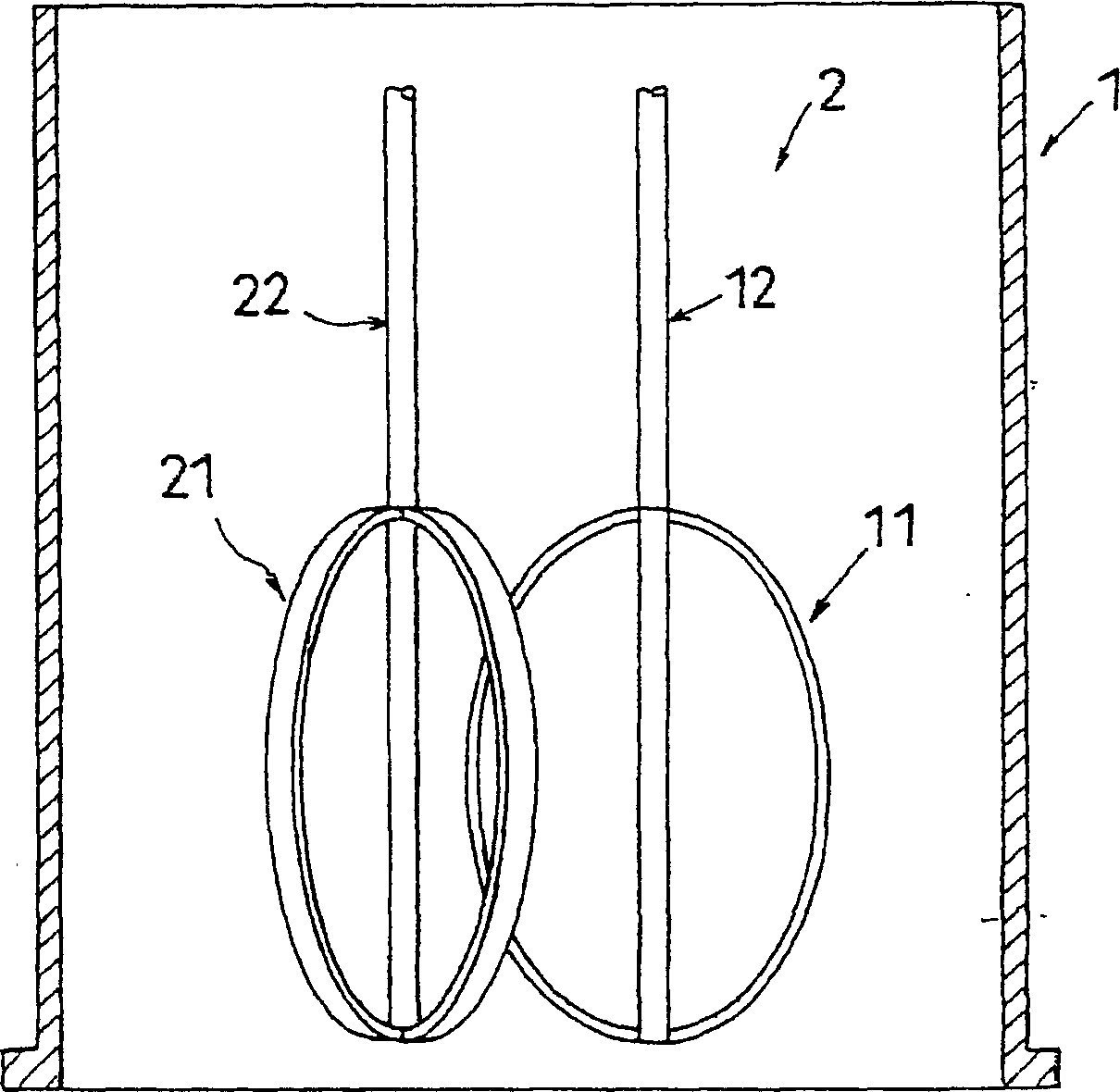

A production method comprising the step of charging prepolymer, a foaming agent and an active hydrogen-containing compound in specified amounts into a tank and foaming / mixing them for a specified time by a mixer, and the subsequent step of pouring the mixture liquid into a metal mold.

Description

technical field [0001] This invention relates to the manufacturing method of the polyurethane foam for polishing pads, and the polyurethane foam manufactured by this manufacturing method. Background technique [0002] A CMP (Chemical Mechanical Polishing) method is currently used as a polishing method for efficiently and accurately smoothing a wiring formation surface on a semiconductor substrate. This is a polishing method that combines chemical action and mechanical action, and can planarize the semiconductor substrate (wafer surface) in a relatively wide range. [0003] As the polishing pad used in this CMP method, there is a material formed of polyurethane foam in which fine depressions can be formed on the surface to retain the polishing slurry. [0004] As a known technique for producing such a polyurethane foam for polishing pads, there is a production method disclosed in JP-A-11-322877. The production method is to add and mix unfoamed heat-expandable tiny hollow sp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B37/00B24B37/24B24D13/14B24D18/00B29C44/34B29C44/36C08G18/00C08G18/08C08G18/10C08G101/00C08J5/14H01L21/304

CPCB24B37/24B24D18/00B24D18/0009B29C44/3442B29C44/36C08G18/10C08G2101/00C08G18/3814

Inventor 濑柳博井上薰

Owner ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com