Method of preparing modified imvite for polymer/inorganic nano composite material

A technology of nanocomposite material and montmorillonite, which is applied in the field of preparation of modified montmorillonite for polymer/inorganic nanocomposite materials, can solve the problems of high cost, use of water or organic solvent, unfavorable popularization and use, etc. Low production cost, no environmental pollution, and the effect of expanding the spacing of montmorillonite layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Get 100 grams of montmorillonite at room temperature, add 1 gram of cetyltrimethylammonium chloride, and stir well;

[0029] (2) The above mixture was stirred and reacted at 150° C. for 10 minutes;

[0030] (3) above-mentioned reaction product is cooled to room temperature and promptly obtains modified montmorillonite of the present invention;

[0031] Take 100 grams of natural rubber, add various compounding agents and the above-mentioned modified montmorillonite according to the commonly used rubber formula, carry out mixing and vulcanization, and the properties of the obtained vulcanized rubber are shown in Table 1. It can be seen from Table 1 that the performance of natural rubber / modified montmorillonite nanocomposites is significantly better than that of natural rubber and unmodified montmorillonite composites, adding 1-10 parts of modified montmorillonite can show significant Reinforcing effect and improved aging resistance.

[0032] natural oak ...

Embodiment 2

[0037] (1) Take 100 grams of montmorillonite and heat it to 50°C, add 50 grams of γ-(2,3 glycidoxy)propyltrimethylsilane, and stir well;

[0038] (2) Stir and react the above mixture at 50°C for 30min;

[0039] (3) above-mentioned reaction product is cooled to room temperature and promptly obtains modified montmorillonite of the present invention;

[0040] Take 100 grams of butadiene rubber, add 5 grams of modified montmorillonite, and add various compounding agents according to the commonly used rubber formula, carry out mixing and vulcanization, and the properties of the obtained vulcanized rubber are shown in Table 2. It can be seen from Table 2 that the performance of butadiene rubber / modified montmorillonite nanocomposites is significantly better than that of butadiene rubber / montmorillonite composites, and 5 parts of modified montmorillonite can show a similar performance to 20 parts of carbon black. Significant reinforcing effect.

[0041] Butadiene rubber ...

Embodiment 3

[0045] (1) Take 100 grams of montmorillonite and heat it to 80°C, add caprolactam and 15 grams each of isopropoxytitanium triisostearate, and stir well;

[0046] (2) Fully stir the above mixture at 100°C for 100 minutes;

[0047] (3) cooling the above reaction product to room temperature to obtain organically modified montmorillonite.

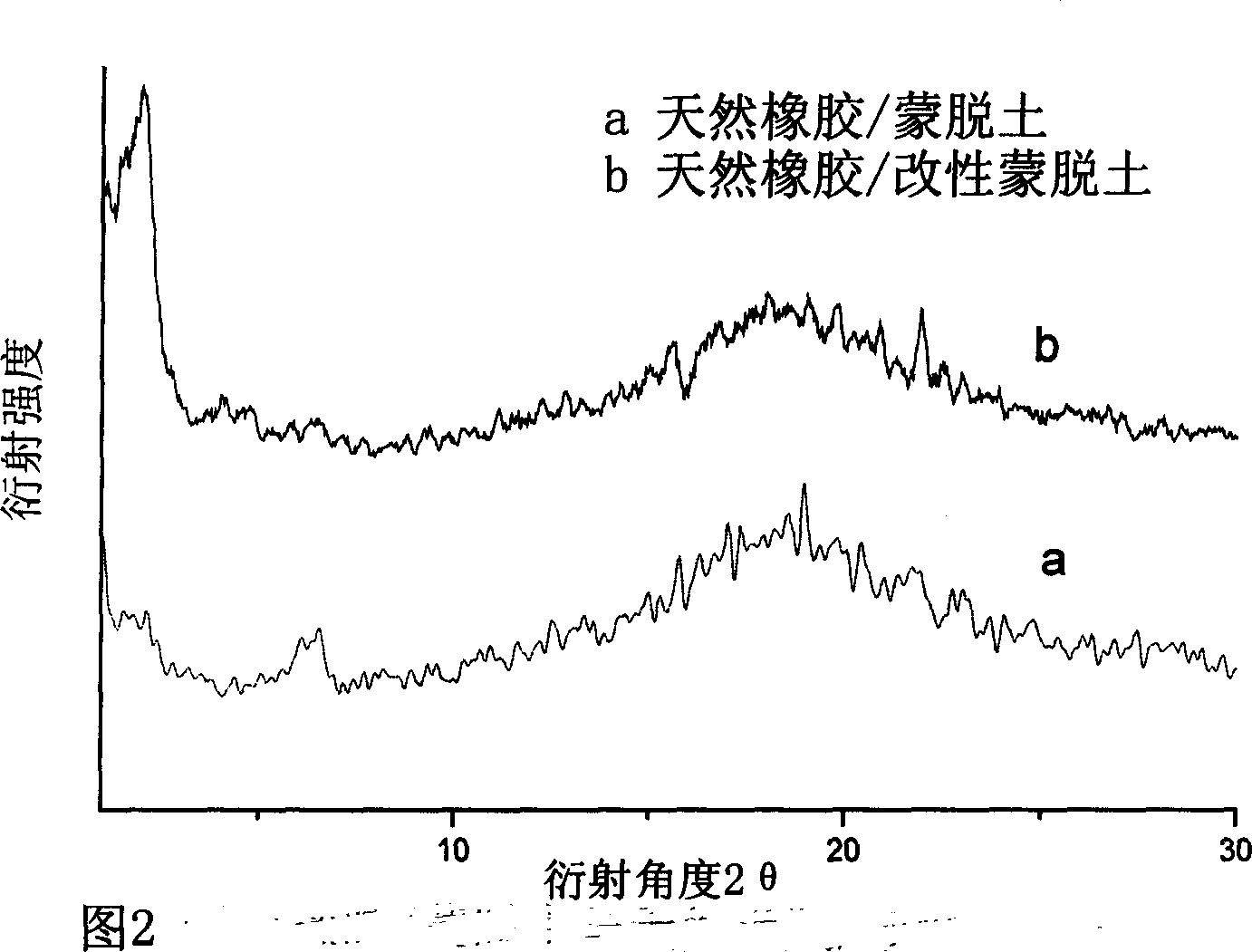

[0048] Take 100 grams of styrene-butadiene rubber, add 30 grams of modified montmorillonite, and add various compounding agents according to the commonly used rubber formula for mixing and vulcanization. Carry out X-ray diffraction analysis to the obtained vulcanizate, find that the interlayer spacing of montmorillonite in this material expands to 4.7nm from original 1.5nm, illustrate that the modified montmorillonite prepared by this method has successfully produced rubber / Montmorillonite nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com