Direct current electrostatic dust collection method and dust collector

An electrostatic precipitator and electrostatic precipitator technology, applied in the field of electrostatic precipitator, can solve problems such as waste of electric energy, difficulty in ensuring operational reliability, and excessive steel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

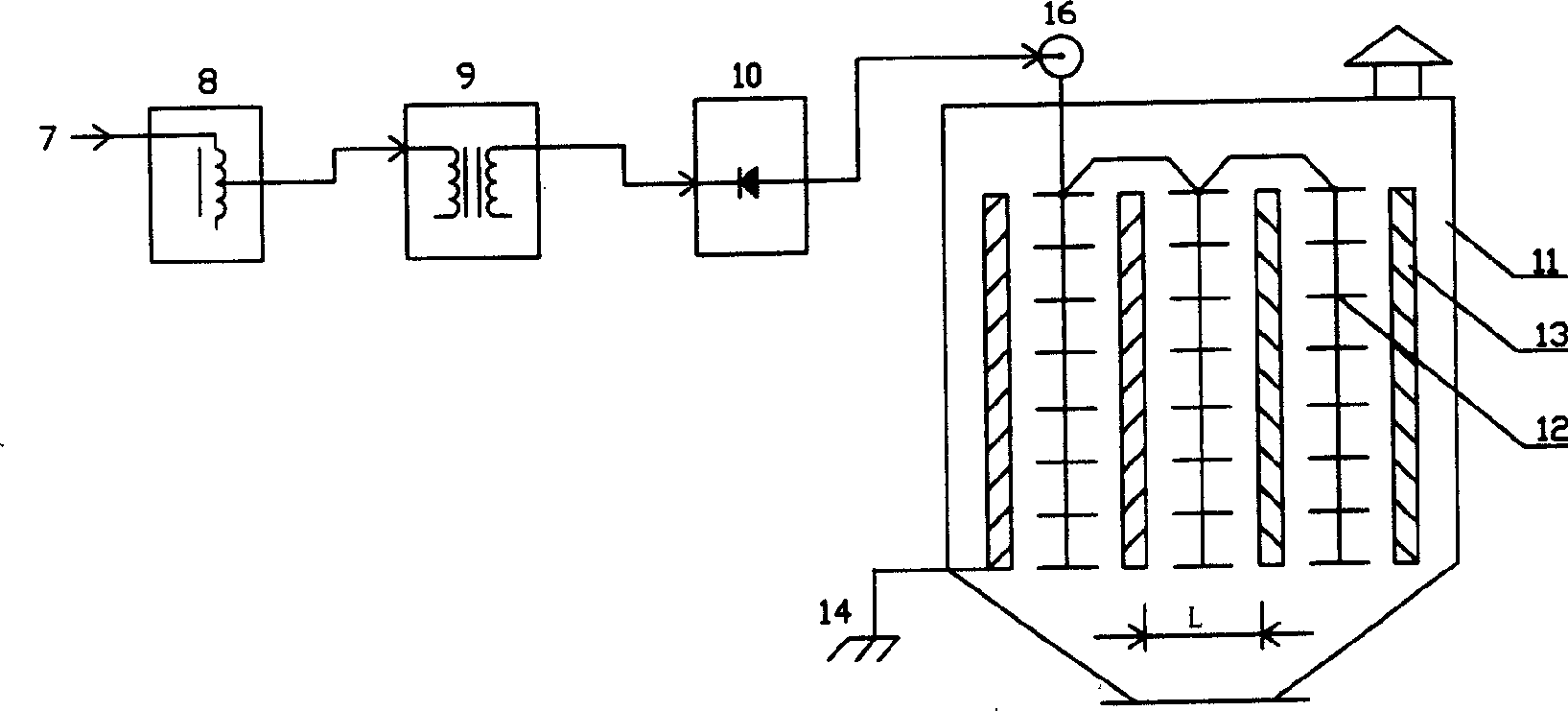

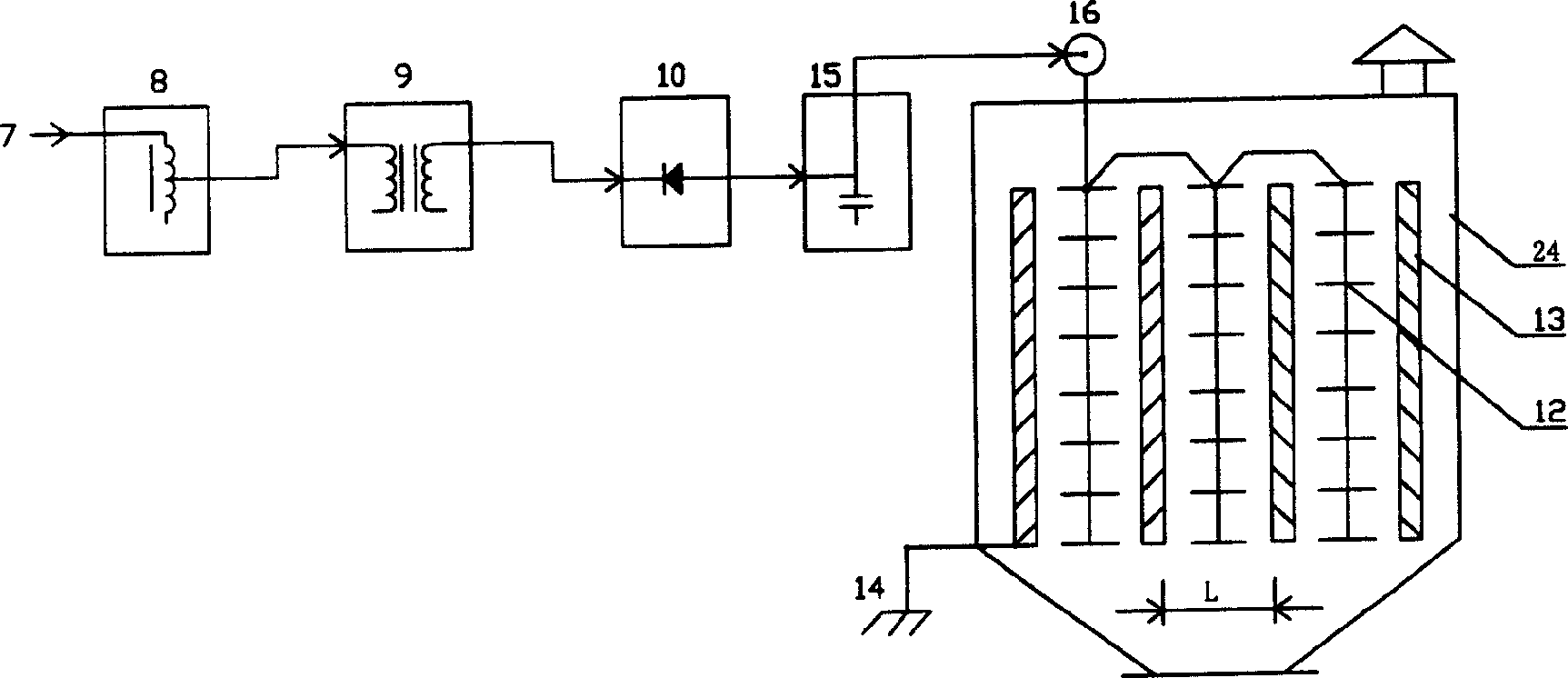

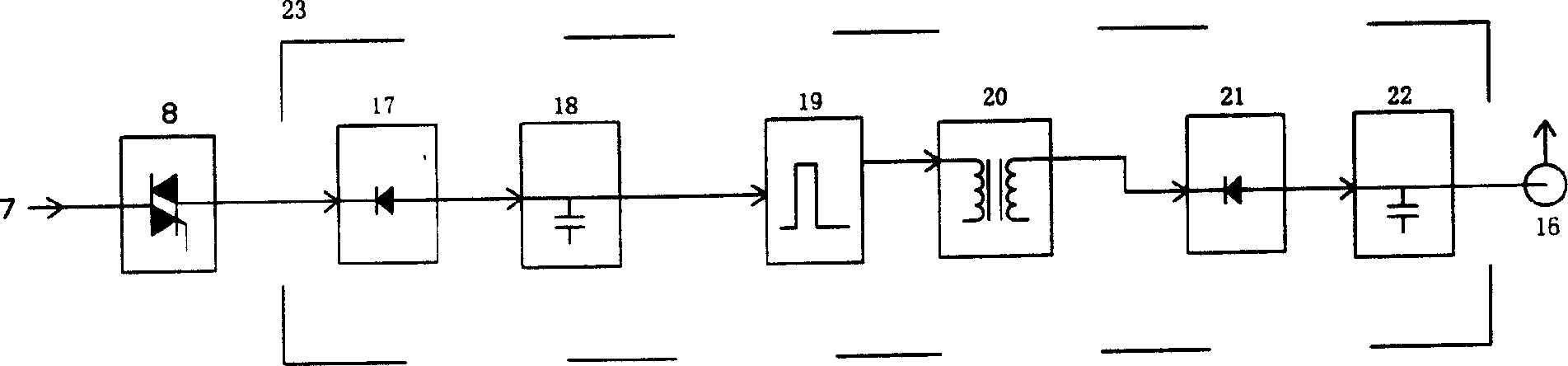

[0029] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0030] Such as figure 2 As shown, the DC electrostatic precipitator 24 of the present invention includes a power input 7, a regulator 8, a power frequency step-up transformer 9, a power frequency high-voltage rectifier (silicon stack) 10, and a high-voltage filter 15, which can be made by ordinary low-frequency capacitors. The electrostatic precipitator 24 body has a power pole line 12, a dust collection pole plate 13, a ground wire terminal 14, and a high-voltage terminal 16. The regulator 8 can be a voltage regulator or a bidirectional silicon controlled rectifier, and the high-voltage filter 15 can be an ordinary low-frequency Capacitors are made, and the distance L between the 13 poles of the dust-collecting plates is preferably 400mm-800mm. The voltage of the 50Hz-50Hz power supply 7 controlled by the regulator 8 is turned into a high voltage by the boost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interval | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com