Mercury less zinc manganese carbon paste battery

A zinc-manganese-carbon, battery technology is applied in the field of mercury-free zinc-manganese-carbon paste batteries to achieve the effects of increasing discharge rate, good electrical conductivity, and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

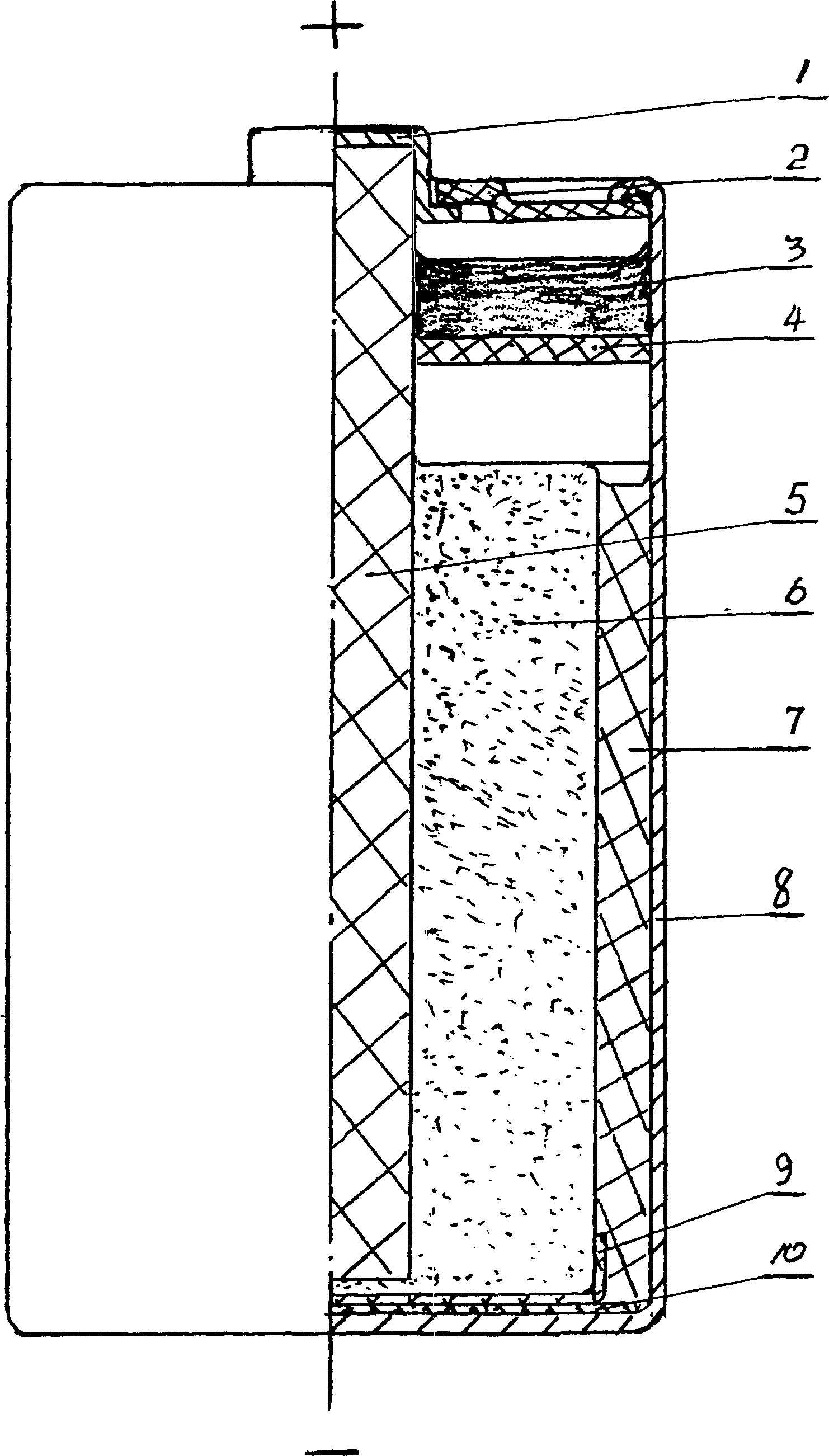

Image

Examples

example 1

[0091] Example 1: Preparation process of mercury-free zinc-manganese-carbon R20S paste battery without wrapping or binding

[0092] 1. Electrolyte formula

[0093] In each liter of electrolyte:

[0094] MgCl 2 ·6H 2 O 13.5%

[0095] NH 4 Cl 12.0%

[0096] ZnCl 2 8.0%

[0097] water balance

[0098] Additional addition: PVA 1.50g

[0099] B(OH) 3 0.30g

[0100] Electrolyte specific gravity 21.5-22.5 degrees Baume

[0101] Electrolyte pH value 5.0-6.0

[0102] 2. Slurry formula

[0104] Total Salt 26.5%

[0105] Powder 21.5%

[0106] water balance

[0107] Also added: InCl 3 0.15g

[0108] PVA 1.50g

[0109] B(OH) 3 0.30g

[0110] 3. Cell formula

[0111] Manganese carbon ratio 87:13 (natural MnO 2 )

[0112] Plus NH 4 Cl 13% (based on the total weight of manganese carbon)

[0113] Cell moisture 21.5-22.5% (Based on the weight of cell powder)...

example 2

[0128] Example 2: Preparation process of mercury-free zinc-manganese-carbon R14S paste battery without wrapping or binding

[0129] 1. Electrolyte formula

[0130] In each liter of electrolyte:

[0131] MgCl 2 ·6H 2 O 14.5%

[0132] NH 4 Cl 13.0%

[0133] ZnCl 2 9.0%

[0134] water balance

[0135] Additional addition: PVA 1.50g

[0136] B(OH) 3 0.30g

[0137] Electrolyte specific gravity 21.5-22.5 degrees Baume

[0138] Electrolyte pH value 5.0-6.0

[0139] 2. Slurry formula

[0140] Per liter of slurry:

[0141] Total Salt 27.5%

[0142] Powder 22.5%

[0143] water balance

[0144] Also added: BiCl 3 0.20g

[0145] PVA 1.50g

[0146] B(OH) 3 0.30g

[0147] 3. Cell formula

[0148] The ratio of manganese to carbon is 87:13 (of which electrolytic MnO 2 20%)

[0149] Plus NH 4 Cl 13% (based on the total weight of manganese carbon)

[0150] Cell moisture 20.5-21.5% (based on the weight o...

example 3

[0166] Example 3: Mercury-free zinc-manganese-carbon R6 cardboard battery

[0167] 1. Electrolyte formula

[0168] In each liter of electrolyte:

[0169] MgCl 2 ·6H 2 O 13.5%

[0170] NH 4 Cl 13.0%

[0171] ZnCl 2 9.0%

[0172] water balance

[0173] Additional addition: PVA 1.50g

[0174] B(OH) 3 0.30g

[0175] 16C Trimethylammonium Chloride 2.0g

[0176] Electrolyte specific gravity 21.5-22.5 degrees Baume

[0177] Electrolyte pH value 5.0-6.0

[0178] 2. Cell formula

[0179] Manganese carbon 87:13 (of which electrolytic MnO 2 25%)

[0180] Plus NH 4 Cl 13% (based on the total weight of manganese carbon)

[0181] Cell moisture 21.5-22.5% (Based on the weight of cell powder)

[0182] 3. Cell Specifications

[0183] Battery powder net weight 7.6-7.8g

[0184] Cell shoulder height 34.0-35.0mm

[0185] Cell molding density ≥2.00g / ml

[0186] 4. Others are the same as the traditional battery technology ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com