Method for measuring factory harmonic wave and measuring instrument

A harmonic and factory technology, applied in the field of measuring harmonic system harmonics in factories, can solve the problem that the harmonic synchronous dynamic change characteristics of harmonic monitoring points cannot be measured, and the network space transmission characteristics of harmonic current systems of harmonic source electrical equipment cannot be measured. , system equipment network compatibility failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiment is described in comparison with the prior art. The embodiment does not discuss the calculation of the power of the electrical equipment that is allowed to access the harmonic source of the power supply system, which does not belong to the description scope of the present invention.

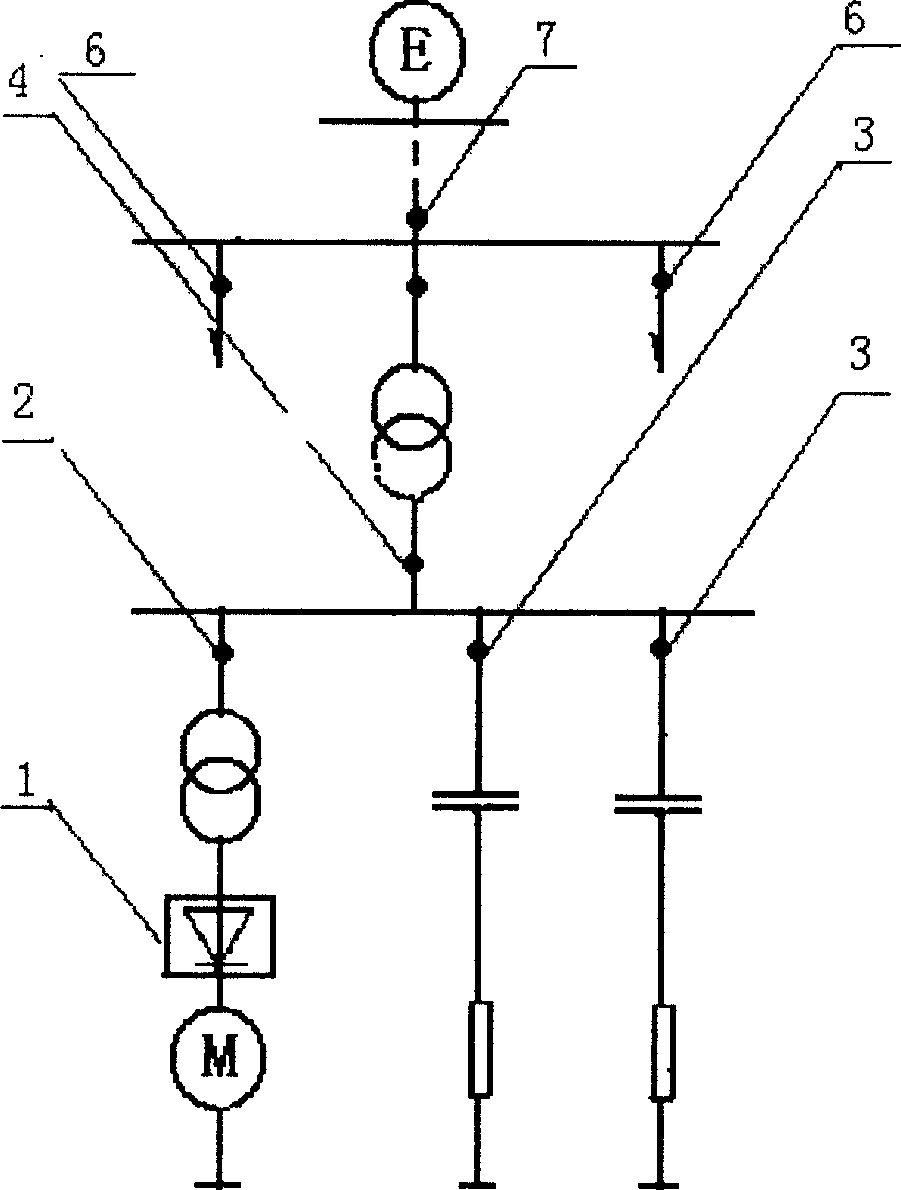

[0042] A rolling mill powered by a converter (1) is used in the rolling mill, and two sets of filters (3) are used on the same busbar of the rolling mill to absorb part of the harmonic current of the converter. However, during the operation of the converter, the The harmonic current at the common connection point (4) exceeds the limit value standard, the reactive power compensation capacitor is overheated and damaged, and the electrical equipment on the same bus is randomly caused to fail.

[0043] The reason is that the prior art cannot measure synchronously in the same steel rolling process before and after the filter is put into operation, each harmonic monitoring point in...

example 2

[0064] Measure the harmonics of the harmonic system of the factory using more than two harmonic source electrical equipment. The difference from the above example is that the transfer function calculation is performed on the results of the Fourier analysis. It is only for the operation of a single harmonic source electrical equipment, or multiple During the operation of the station, only a single harmonic source electrical equipment bus connection point has the Fourier analysis results of the short time course of the harmonic current, and calculates the transfer function, and simultaneously measures the time change of the harmonic current level at the harmonic source electrical equipment bus connection point , The distribution of system network space changes, that is, the time change distribution characteristics of the harmonic current at the bus connection point of two harmonic source electrical equipment at the common connection point of the system network space and the filter...

example 3

[0066] The power supply department uses the common connection point (4) (6) as a harmonic current source to measure the harmonic current at the common connection point of each factory and the harmonic current and harmonic voltage drop superposition of the busbar (7) at the common connection point of the power supply system . In the prior art, sampling is performed at each public connection point at long intervals during the production process of the factory, and the harmonic injection is evaluated by a 95% probability statistical method, and any sampling probability statistical method has no repeatable results. The method of the invention is to measure the common connection point of each factory synchronously and continuously and the harmonic current and the harmonic voltage drop of the common connection point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com