Method and device for detecting gas content of mixed fluid under while drilling condition

A technology of mixing fluids and detection devices, which is used in measurement, earthmoving, wellbore/well components, etc., and can solve problems such as inaccurate measurement results and lag in detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

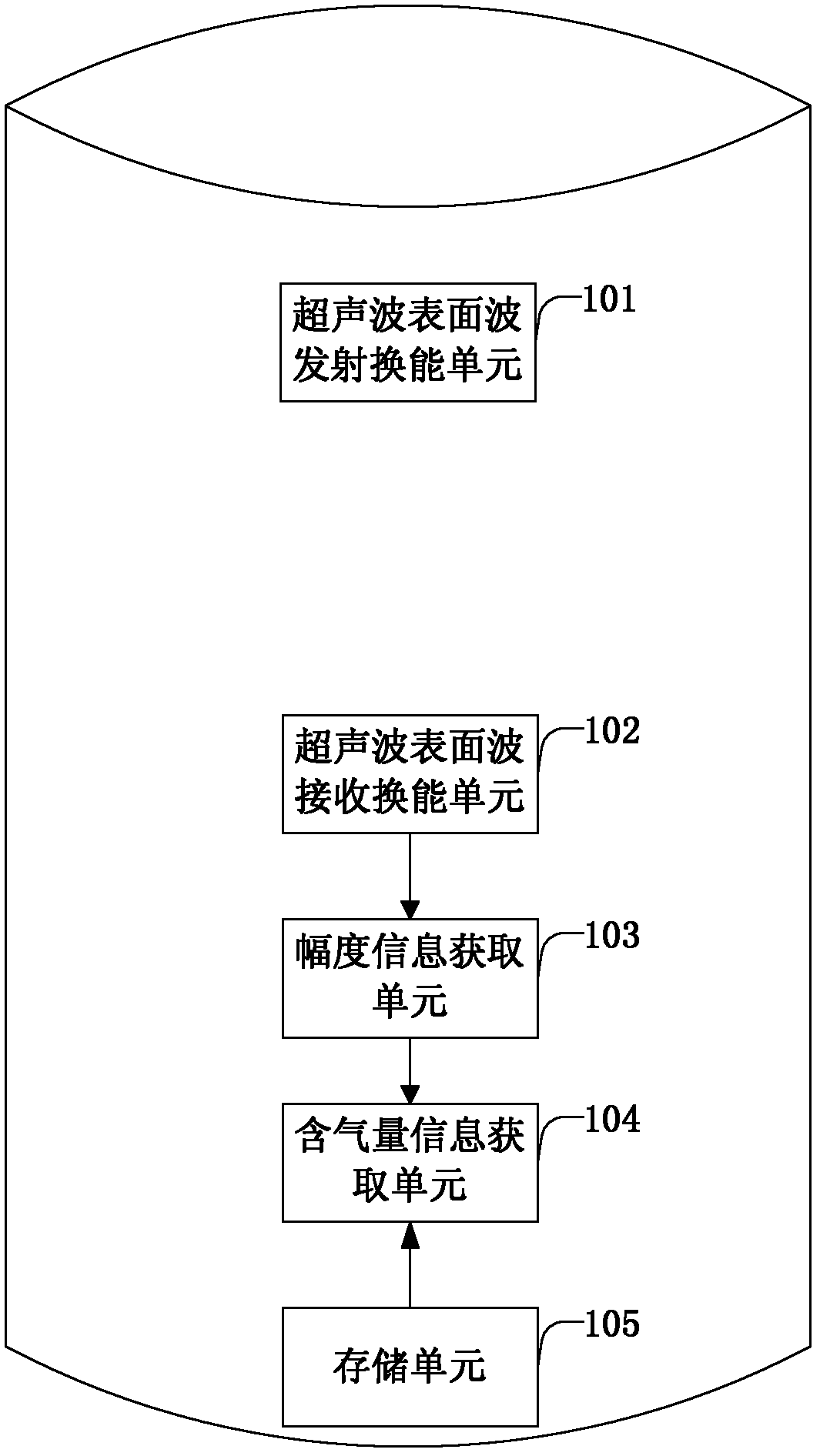

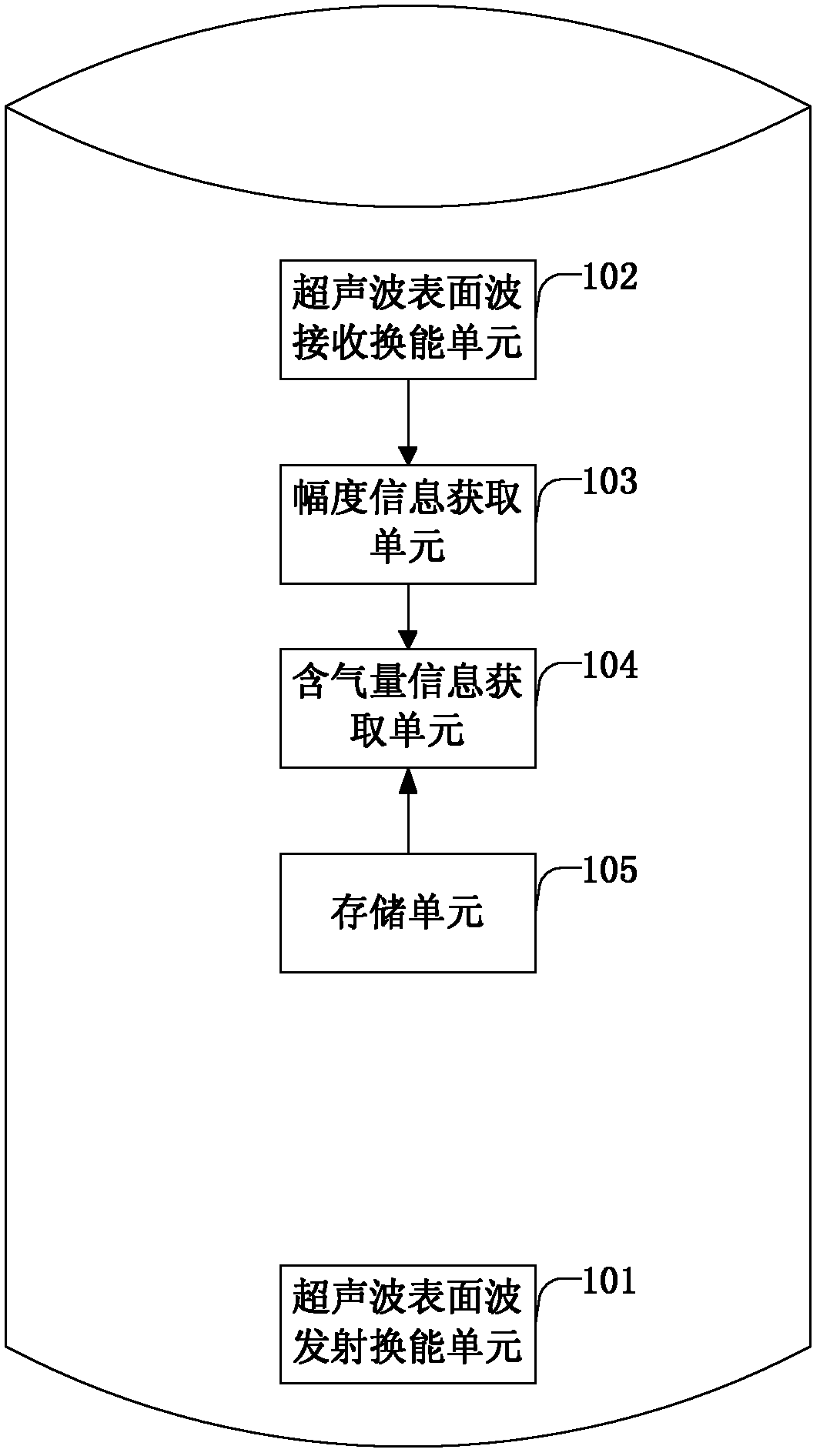

[0029] figure 1 It is a structural diagram of a mixed fluid gas content detection device under the condition of drilling provided by the embodiment of the present invention, as shown in figure 1 As shown, the gas content detection device includes: a surface ultrasonic wave transmitting and transducing unit 101 , a surface ultrasonic wave receiving transducing unit 102 , an amplitude information obtaining unit 103 , a gas content information obtaining unit 104 and a storage unit 105 . Focusing on the practicability of the probe, easy disassembly and interchange, and independent testing and verification of the probe function, the ultrasonic surface wave sensors involved in the embodiments of the present invention all adopt a modular structure, and these probe modules are composed of piezoelectric vibrators and necessary The packaging components can respectively have the functions of transmitting ultrasonic surface wave signals and receiving ultrasonic surface wave signals, and c...

Embodiment 2

[0043] Figure 4 It is a flow chart of a method for detecting the gas content of mixed fluid under drilling conditions provided by the embodiment of the present invention, as shown in Figure 4 As shown, the gas content detection method comprises the following steps:

[0044] S401. Generating ultrasonic surface waves through electric signal excitation.

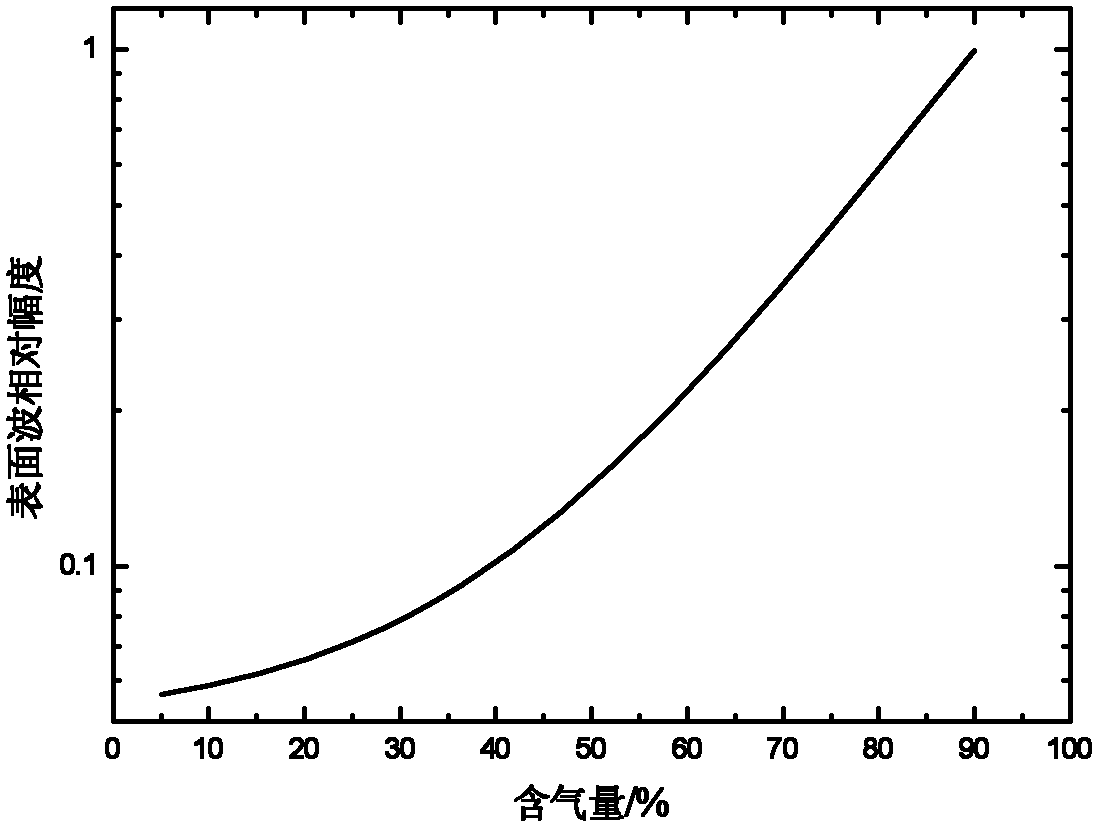

[0045] In the embodiment of the present invention, the gas content detection method can be realized by the gas content detection device in Embodiment 1. The gas content detection device can have an ultrasonic surface wave transducer, and its operating frequency range is about 0.5 MHz to 3 MHz. Here The wavelength of the ultrasonic surface wave in the working frequency range is much smaller than the wall thickness of the drill collar, so the drill collar can be regarded as a semi-infinite solid medium, and the fluid outside the outer surface of the drill collar can be regarded as a mixture of liquid and gas composite fluid me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com