Mixed optical cable with sensing and communication function and producing method thereof

A technology of communication optical cable and communication function, which is applied in the field of communication sensing, can solve the problems of easy damage in laying and use, short effective service life, poor protection performance, etc., and achieve reasonable and simple production method, high working stability and protection performance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

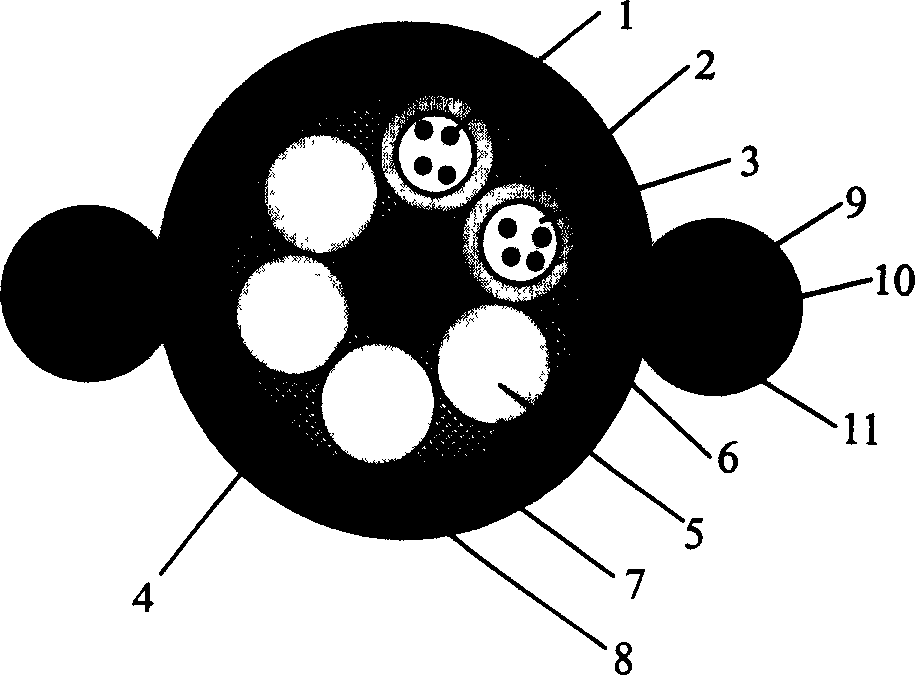

[0018] Example as figure 1 As shown, the communication optical cable is composed of a loose-tube layer-stranded optical cable core covered with an outer sheath. The loose-tube layer-stranded optical cable core includes a central strength member 4, which is stranded in the circumferential direction of the central strength member and contains the optical fiber 1. The loose tube 2 and the filling rope 5, the loose tube is filled with fiber paste 3, and the loose tube is provided with water-blocking parts or filled with water-blocking material 6, and then longitudinally wrapped with a metal tape 7 to form a loose-tube layer twisted optical cable Core, the outside of the cable core is an outer sheath 8; on one or both sides of the outer sheath, a sensing optical cable is arranged, and the sensing optical cable and the outer sheath are connected into one body, and the additional set can be processed by extrusion molding through one-time molding technology. part of the sensor cable. ...

Embodiment 2

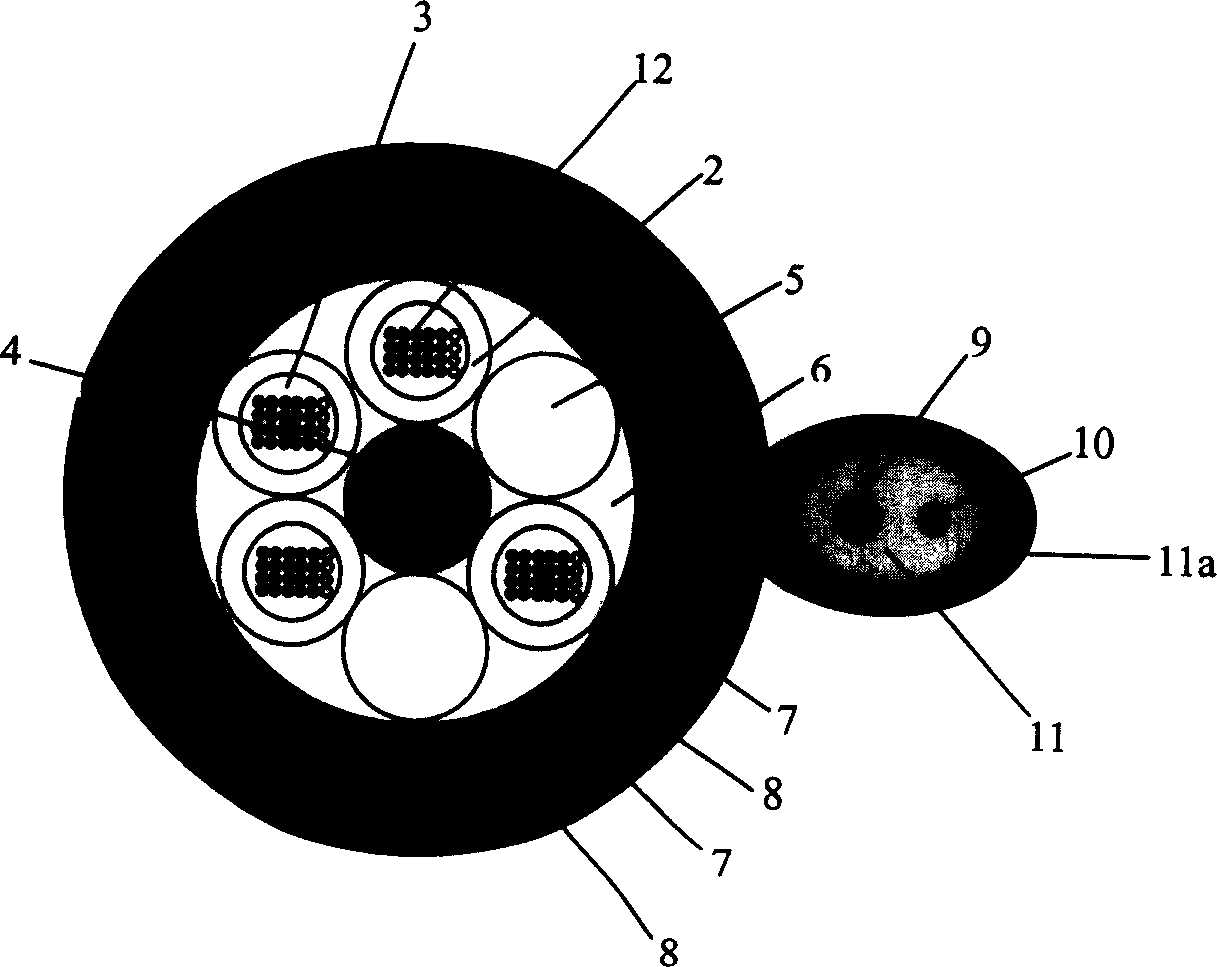

[0019] Example two such as figure 2 As shown, it is characterized in that the cable core of the communication optical cable is a loose tube stranded optical fiber ribbon structure, that is, the loose tube 2 of the cable core is covered with a superimposed optical fiber ribbon 12, and a sensor sensor is connected to one side of the communication optical cable. The optical cable, the sheath 11 of the sensing optical cable is integrated with the outer sheath 8 of the communication optical cable. The sheath can be elliptical, and a sensing optical fiber 10 and a strengthening member 9 are installed in the sheath, wherein the sensing optical fiber is located On the outside of the sheath, the strength member is located on the side close to the communication optical cable. Other structures are the same as the previous embodiment.

Embodiment 3

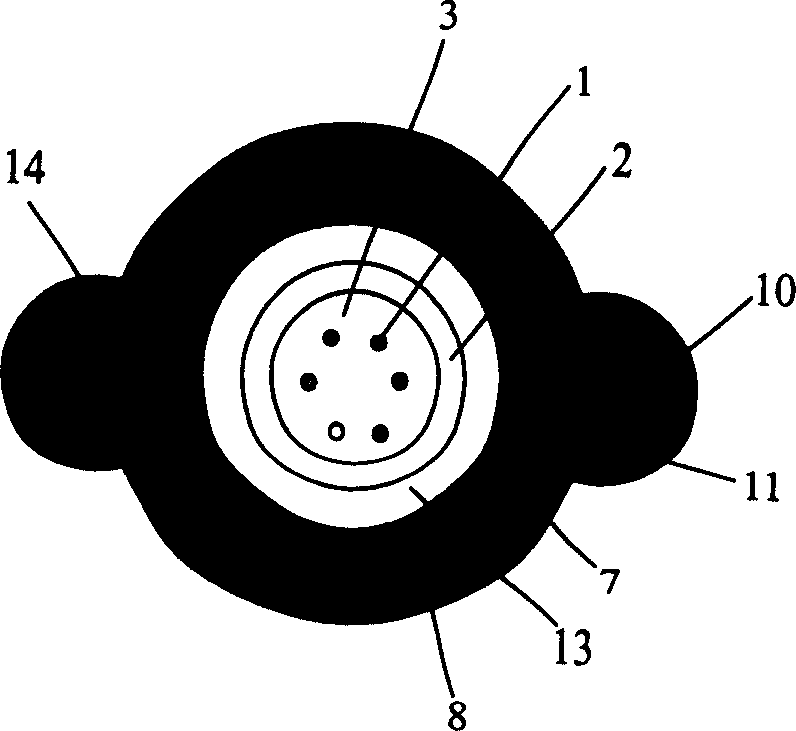

[0020] Embodiment three such as image 3 As shown, the cable core of the communication optical cable is a central bundle tube structure, including a loose tube 2 containing optical fibers, the loose tube is filled with fiber paste 3, and a water-blocking layer 13 is arranged outside the loose tube, and the water-blocking layer is longitudinally covered with metal. Belt 7; the outer sheath 8 is covered outside the longitudinal metal belt, and strengthening elements 14 are installed on both sides of the outer sheath, and a sensing optical cable is respectively extruded on the outer sheath outside the two strengthening elements, and the sensing The section of the sheath 11 of the optical cable is in the shape of an arc ear, and the sensing optical fiber 10 is laid in the sheath.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com