Completely cutting tool for shaving and honing gear and its usage

A technology for gear cutters and shaving cutters, which is applied to gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., and can solve problems such as affecting tool durability and rapid wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The design calculation and experimental analysis of the tool with a modulus of 3.75mm can make each blade fully capable of continuously participating in cutting from the root of the tooth to the top of the tooth. This improvement alone increases the life of the tool by at least 10 times. The larger the modulus, the longer the life.

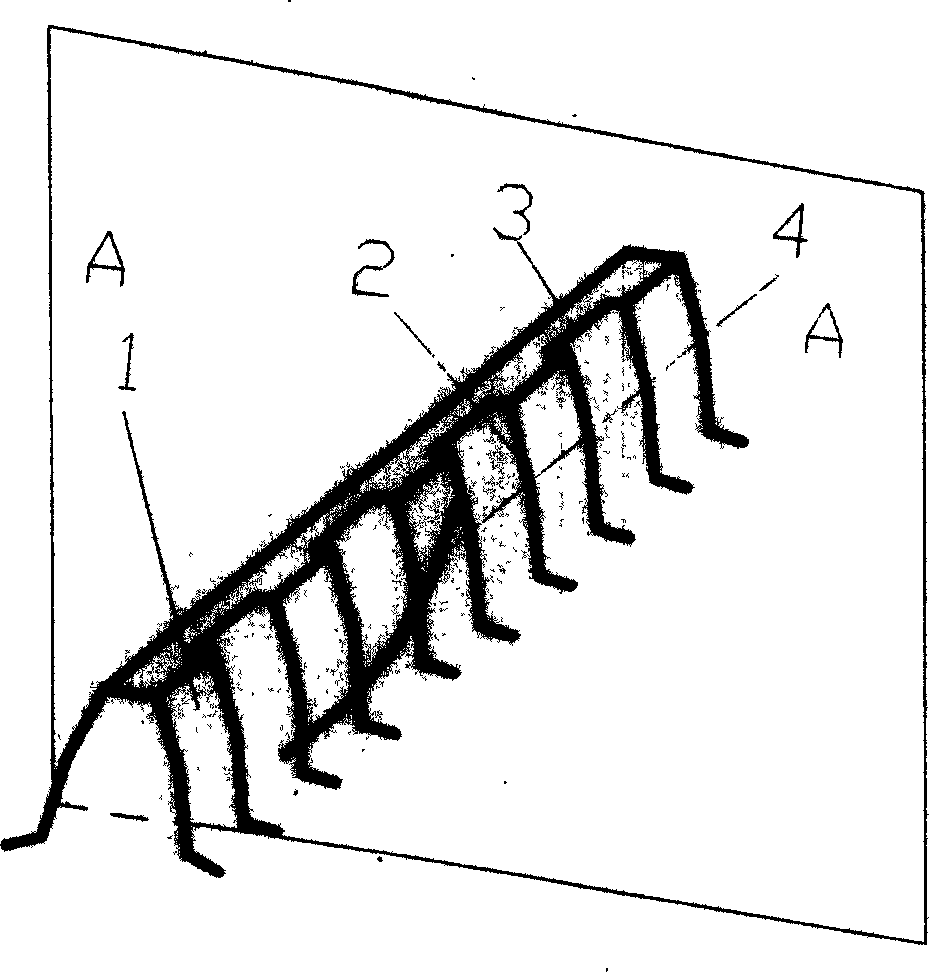

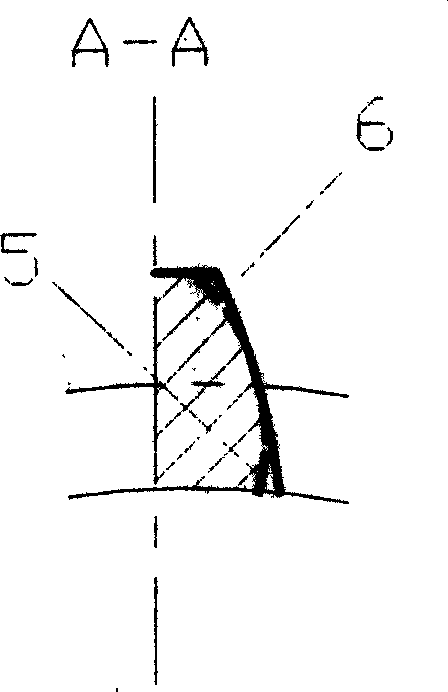

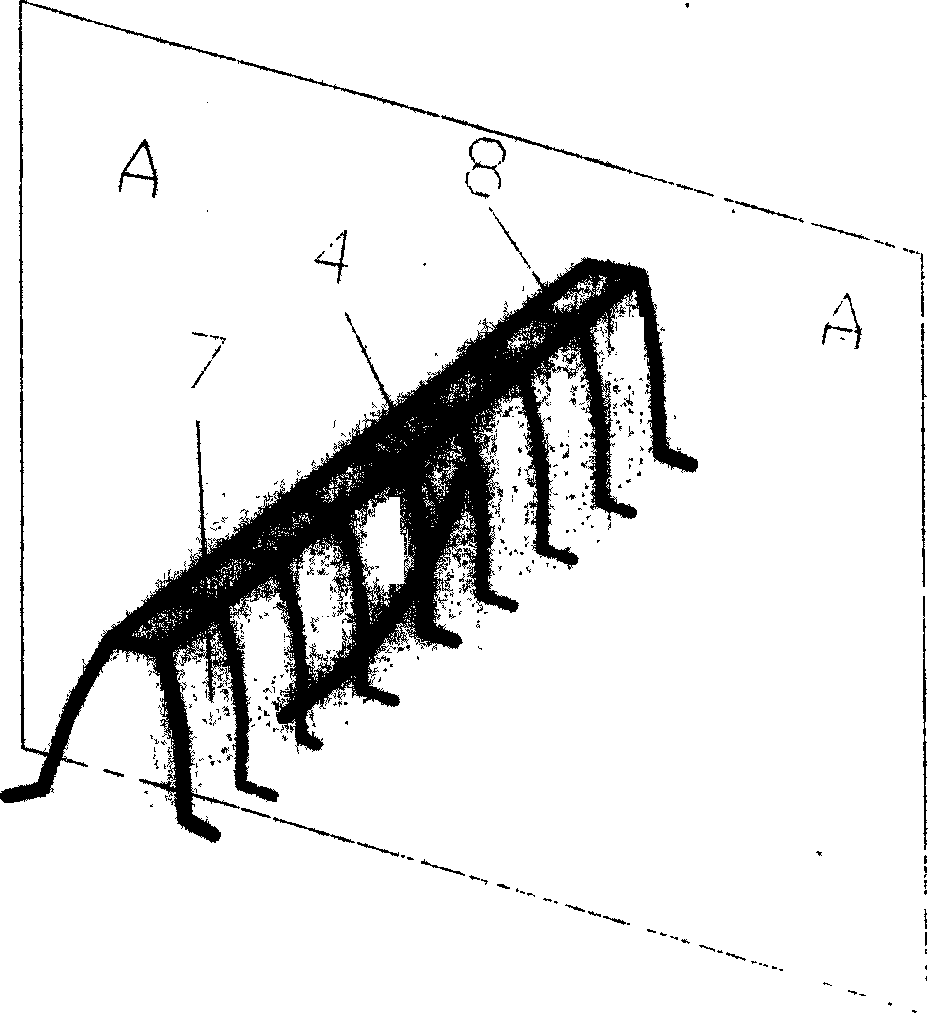

[0069] We have developed a computer-aided design program (PICM), which can fit the projected curve of the tooth end surface closely related to the contact line of the tooth surface into an approximate involute end section tooth profile with full cutting function, namely knife-edge curves (such as figure 1 , figure 2 and image 3 , Figure 4 shown), and the error is very small. The approximate involute tooth shape has the corresponding base circle diameter and pressure angle correction value. According to any parameter, the full-cut end section tooth shape (that is, the blade shape) can be ground on the gear grinding machine, that is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com