Locking pin having anti-pumping device

A technology of anti-jumping and locking pins, which is applied in the direction of railway couplings, railway car body parts, transportation and packaging, etc., can solve problems such as detachment and anti-jump failure, and achieve convenient maintenance, reliable anti-jumping effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

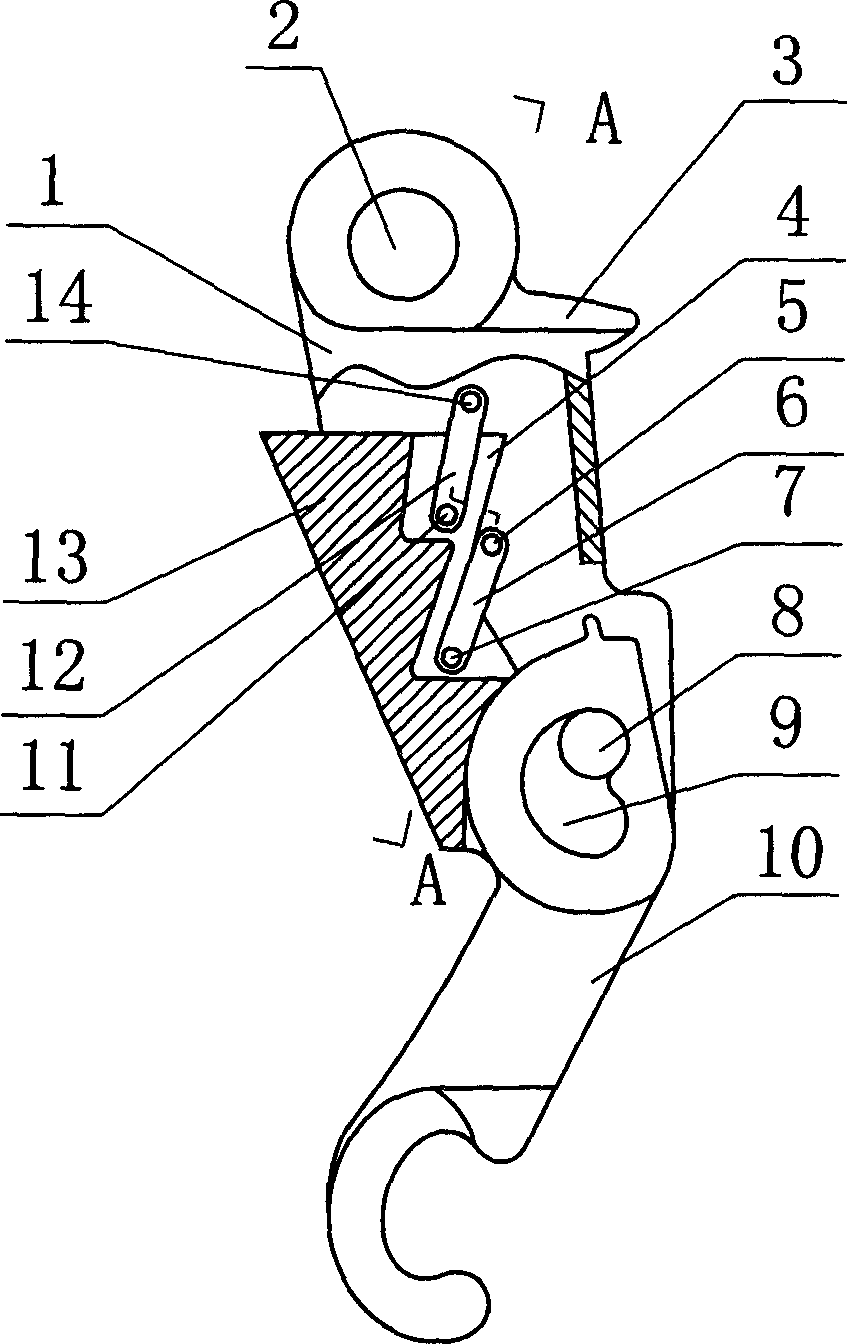

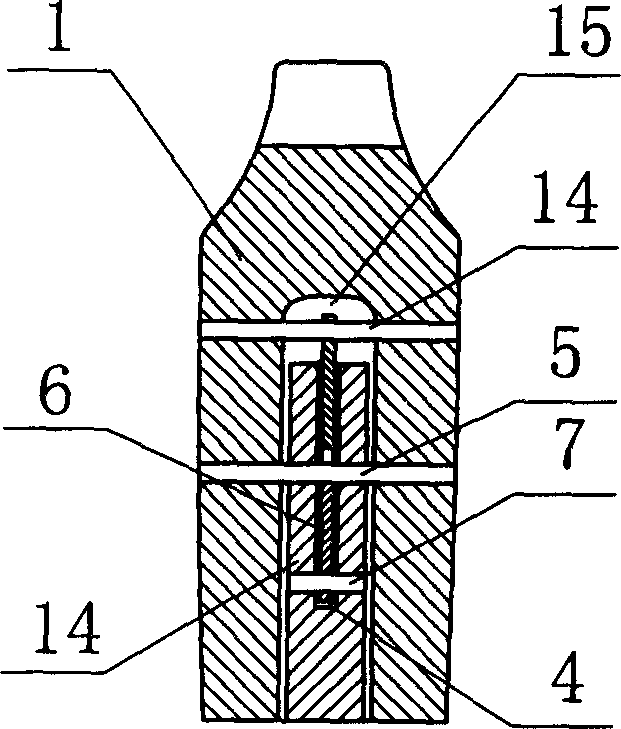

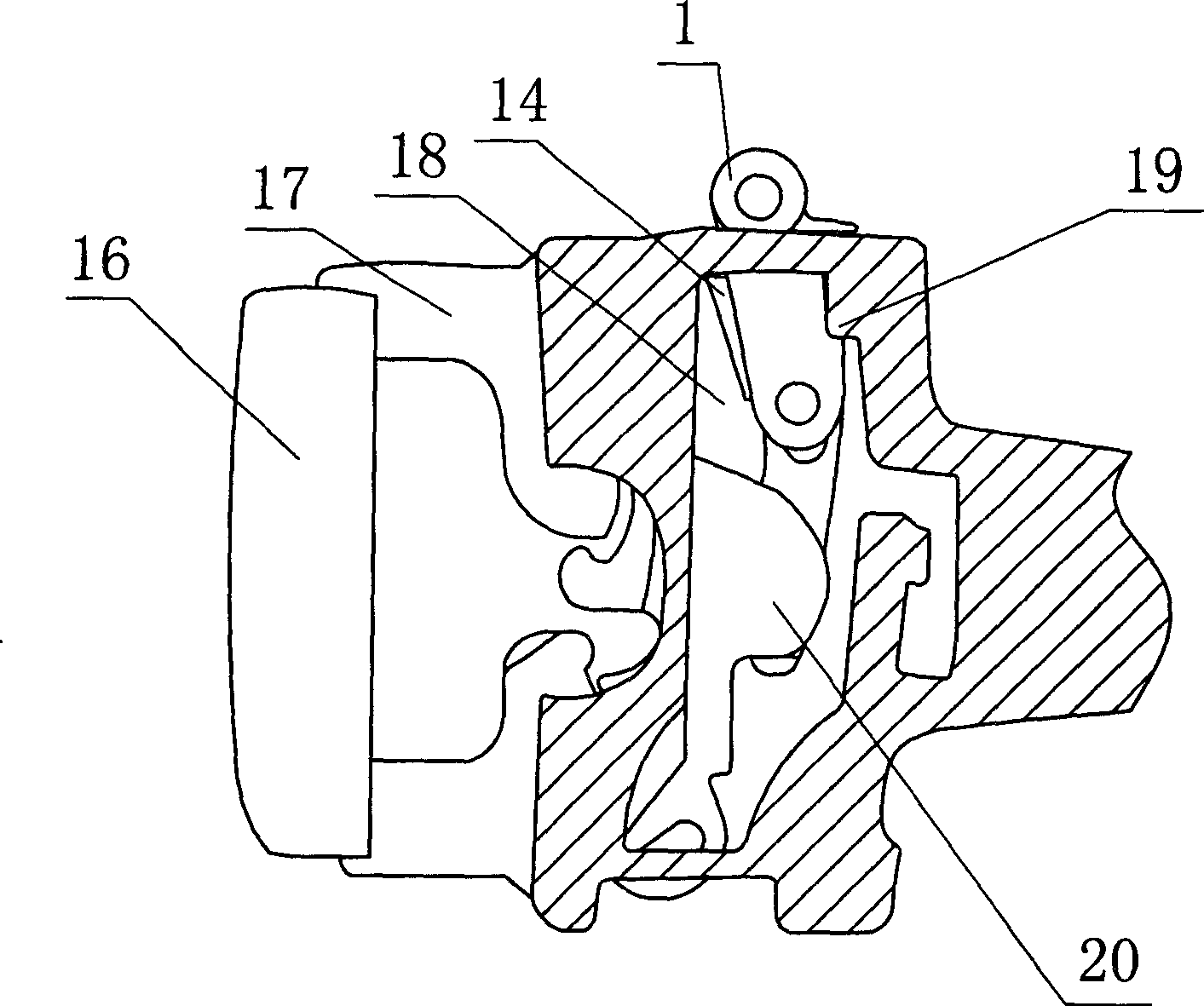

[0015] As shown in the figure, the present invention has an upper lock pin body 1, a connecting hole 2 is arranged on the top of the upper lock pin body 1, the front end surface of the upper lock pin body 1 is a slope, and the upper lock pin body 1 is provided with a The card edge 3, the lower part of the upper lock pin body 1 is provided with a mounting hole, and the upper lock pin rod 10 is installed through the pin shaft 8 in the installation hole, and the connecting hole corresponding to the upper lock pin rod 10 and the pin shaft 8 is the "heart" Shaped hole 9, through the motion between " heart " shape hole 9 and bearing pin 8, plays the positive compensation effect for the anti-jumping of vehicle coupler, realizes vehicle coupler anti-jumping. Upper lock pin body 1 is provided with chute 15, and the front end face of chute 15 is open, is connected with anti-jump iron 13 by upper and lower connecting rod 12,6 in chute 15, said anti-jump The iron 13 is provided with an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com