Retaining system for a rotor of a dynamoelectric machine

A technology of generator rotor and holding system, applied in electromechanical devices, electrical components, electric components, etc., to achieve the effect of simple structure, high cost, and large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

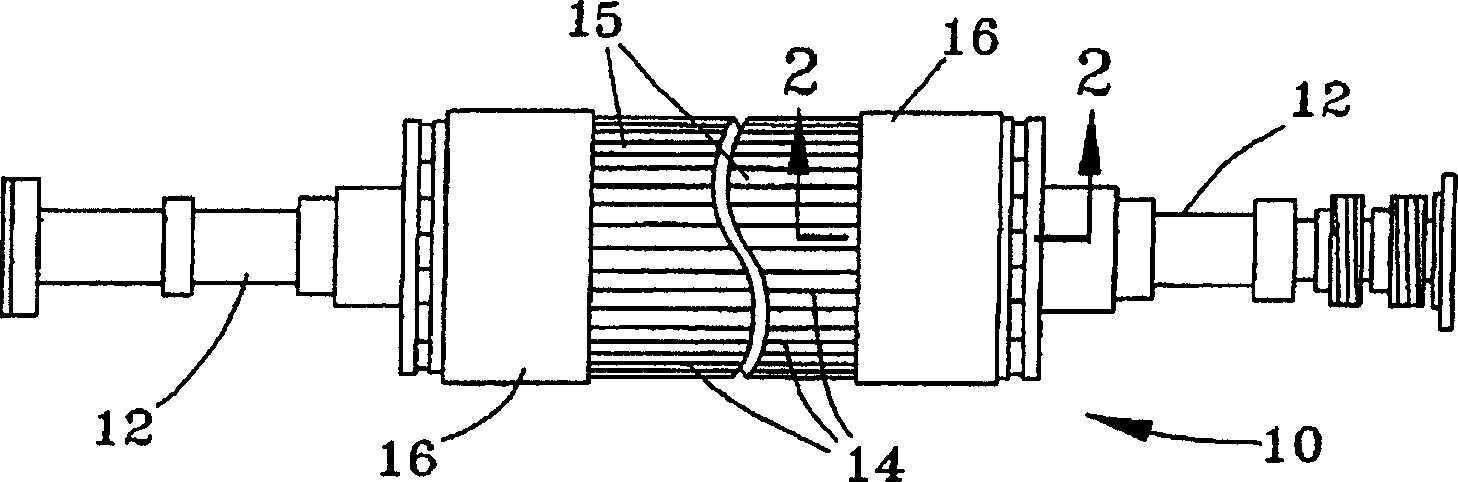

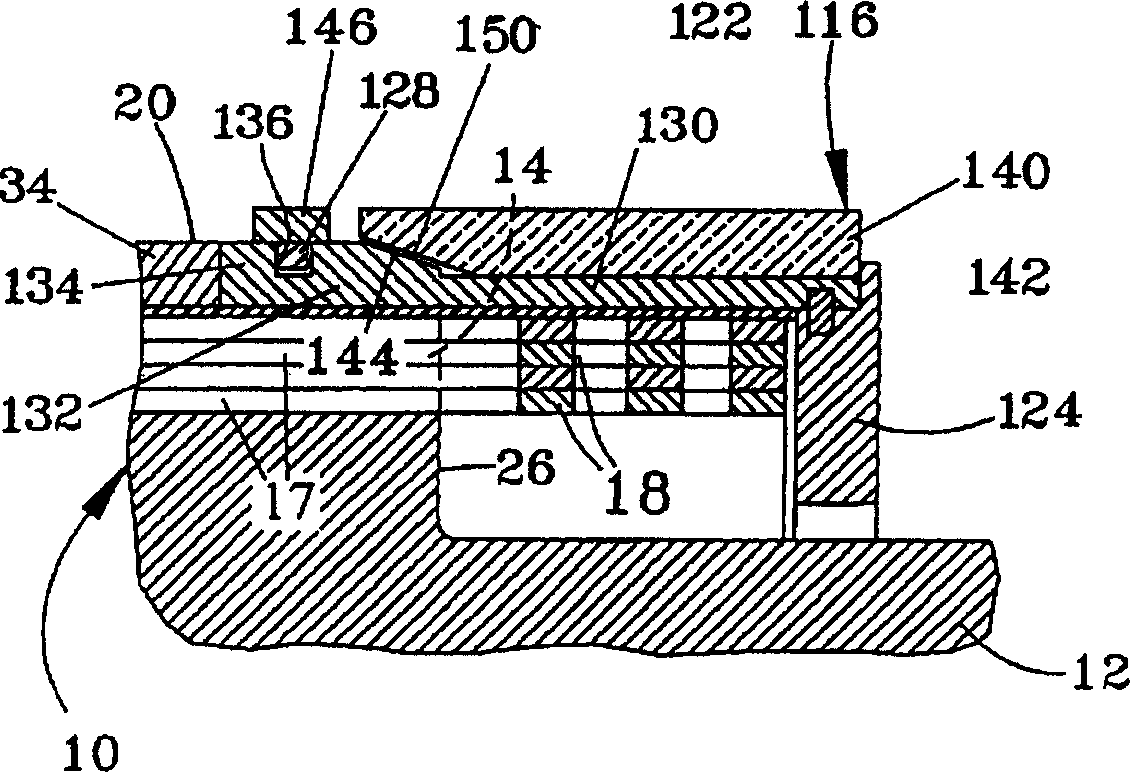

[0035] image 3 and 4 are with figure 1 and 2 The rotor 10 is similar to the partial cross-sectional view of the rotor 10, so the same reference numerals are used here to identify the same or equivalent functional parts of the rotor 10. Likewise, a rotor 10 of this type can also be used in power plants, which are used as the main supplier of high voltage alternating current for distribution or transmission grids, but the rotor 10 can be used in other applications.

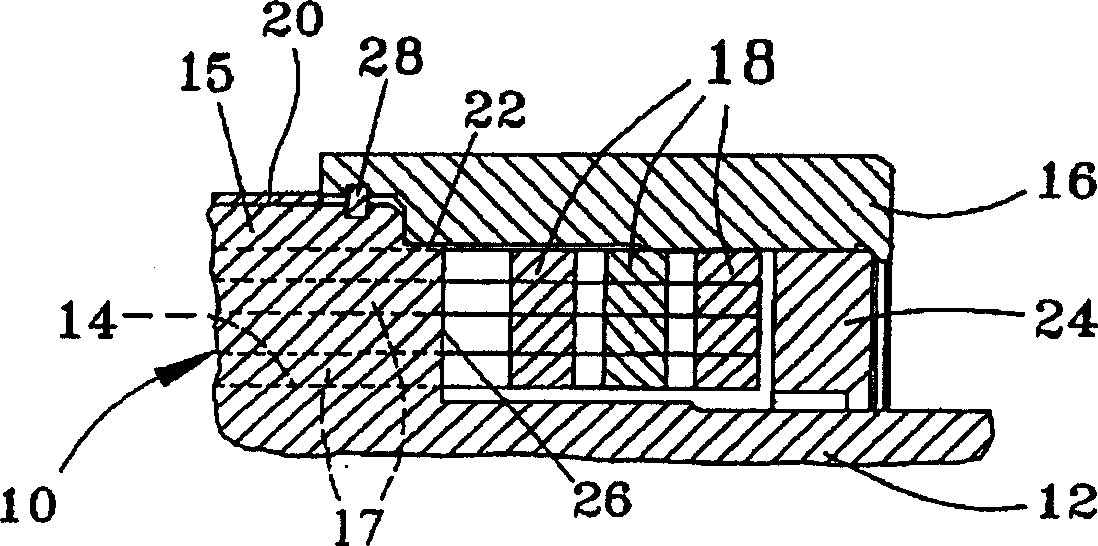

[0036] as figure 1 and 2 Like the rotor 10 in the image 3 The rotor 10 in and 4 has a cylindrical body with an outer surface 20 and radial end faces 26 at opposite ends of the cylindrical body. Furthermore, the slots 14 are on the outer surface 20 of the rotor 10, forming radially extending teeth 15 on the outer surface 20 (FIG. 4). The field winding 17 is located in the slot 14 and protrudes axially from the end face 26 of the rotor 10 . As can best be seen in FIG. 4 , the cross-sectional shape and dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com