Locking mechanism for reverse gear shift fork shaft of transmission

A shift fork and locking mechanism technology, applied to mechanical equipment, components with teeth, transmission control, etc., can solve the problem of damage to the canine teeth of the synchronizer ring of the transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

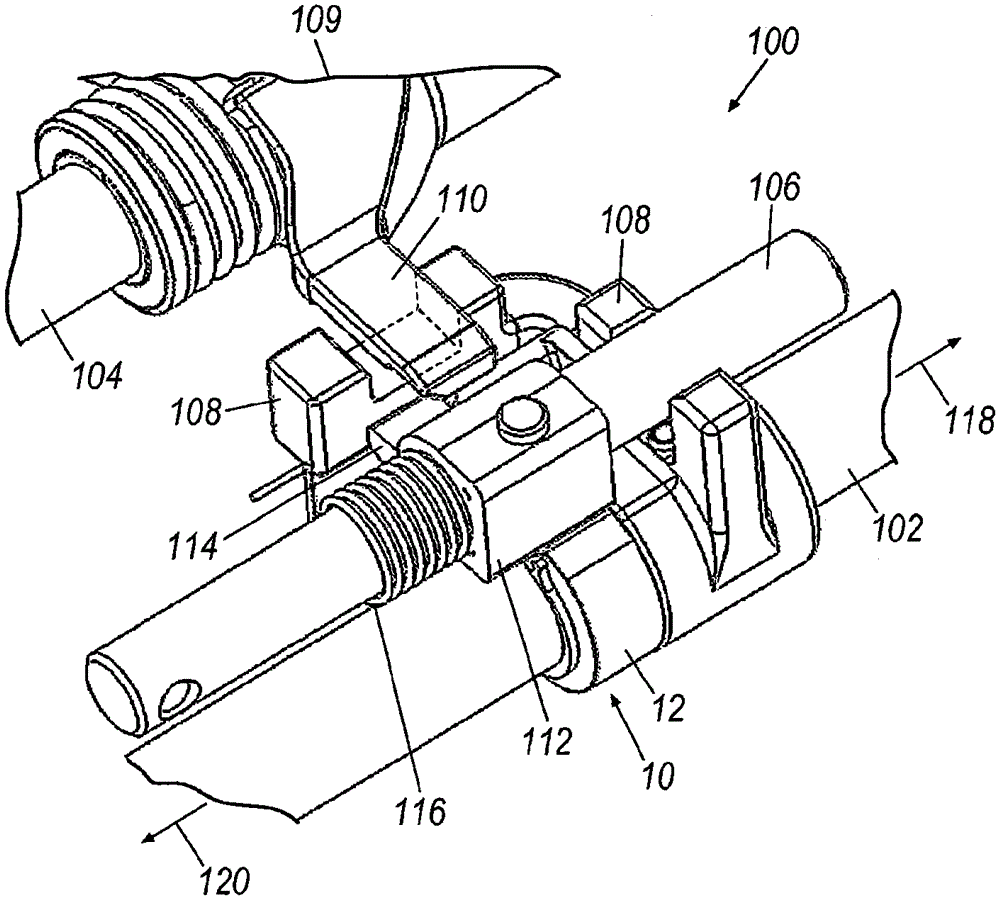

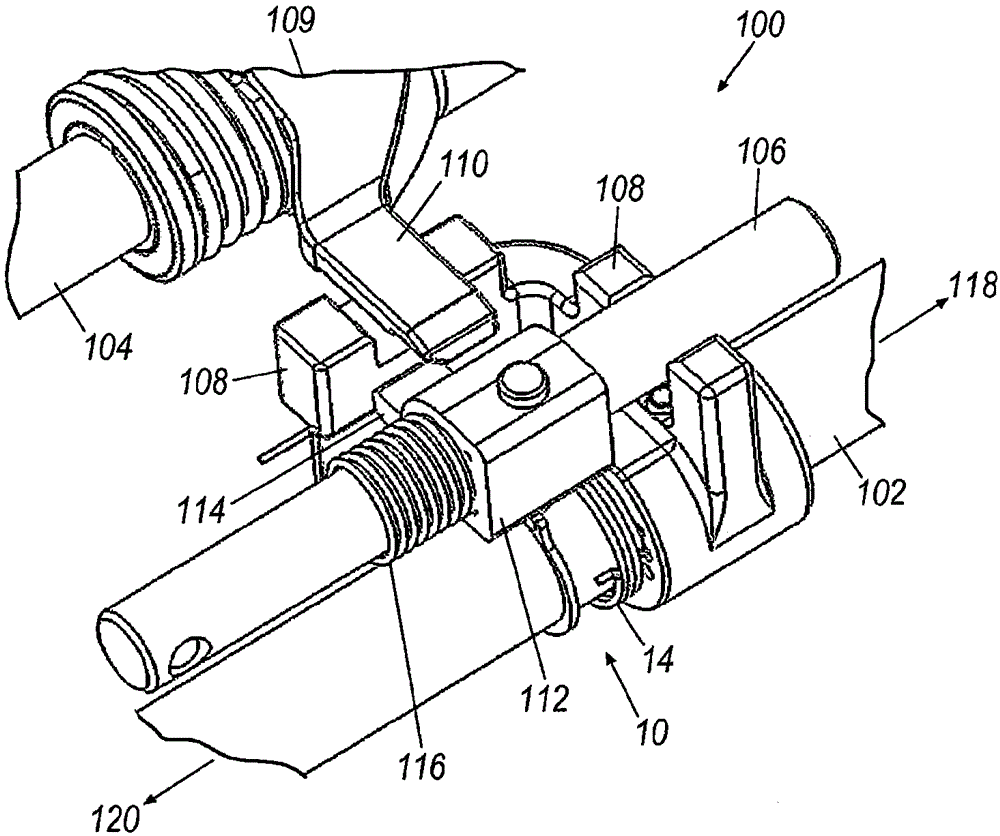

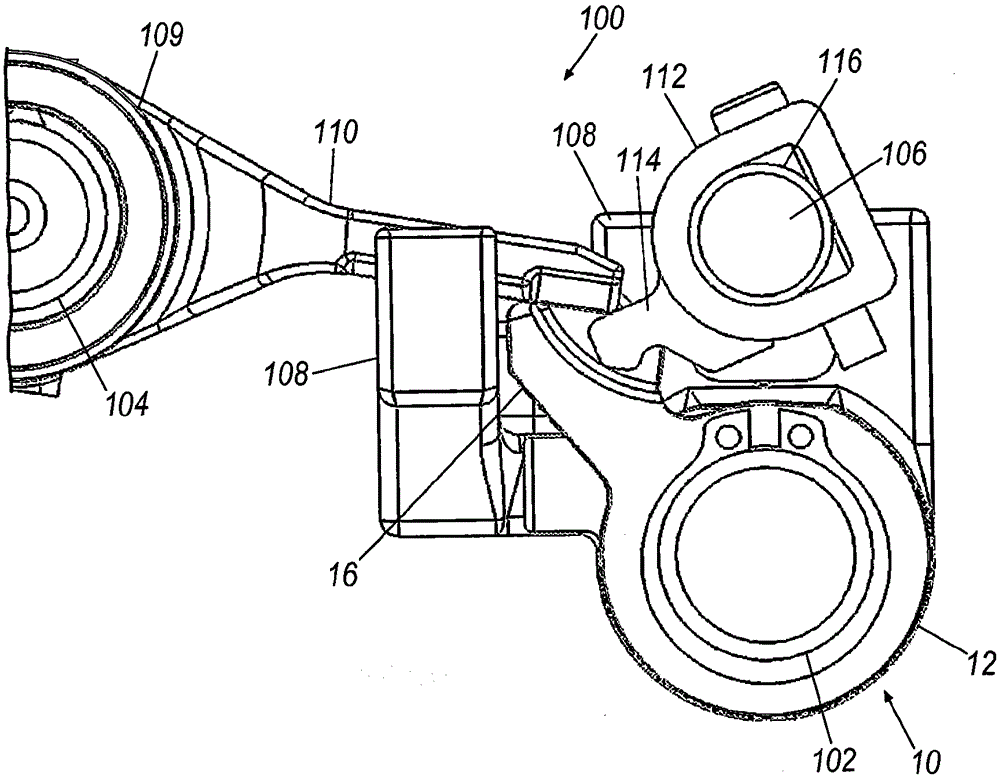

[0026] An exemplary transmission, such as a five-speed transmission, may include a reverse shifter shaft for placing the transmission in a reverse range or another drive range (eg, fifth gear). The shift fork shaft may be configured to move axially in a first direction for a drive range and in a second direction for a reverse range.

[0027] In addition to the reverse shift fork shaft, the example transmission may also include a main shift fork shaft and a reverse inhibitor. The main shift fork shaft may have a fork shaft selector having laterally extending wings configured to selectively engage the reverse shift fork shaft to enable reverse shifting The shift fork shaft can move axially. The reverse inhibitor may be configured to selectively inhibit movement of the reverse shift fork shaft in a second direction toward the reverse range when the reverse shift fork shaft is disengaged from the drive range.

[0028] When disengaging the transmission from a drive range, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com