Heat insulating construction for piping and heat insulating tool kit

A technology of thermal insulation and complete set of tools, applied in pipeline protection, thermal insulation, pipeline protection through thermal insulation, etc., can solve problems such as troublesome, unsuitable for multiple use, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be specifically described below with reference to the drawings.

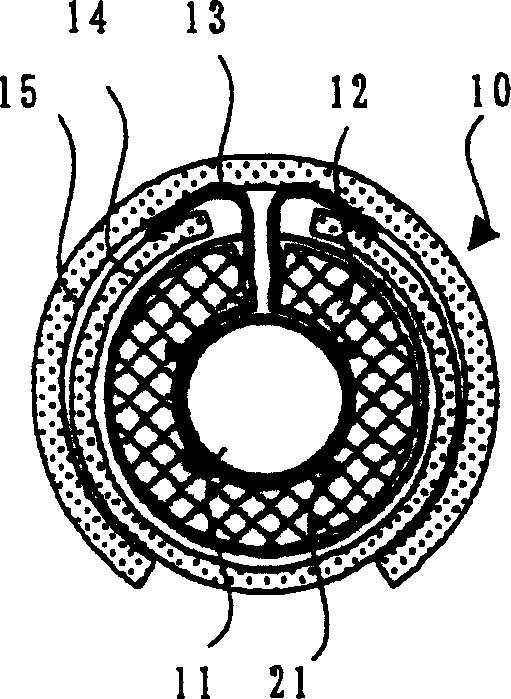

[0041] figure 1 It is an explanatory cross-sectional view of a heat insulation structure in which a heat insulation kit including the heat insulation unit of the present invention, a support cover, and an outer cover is installed on a pipe.

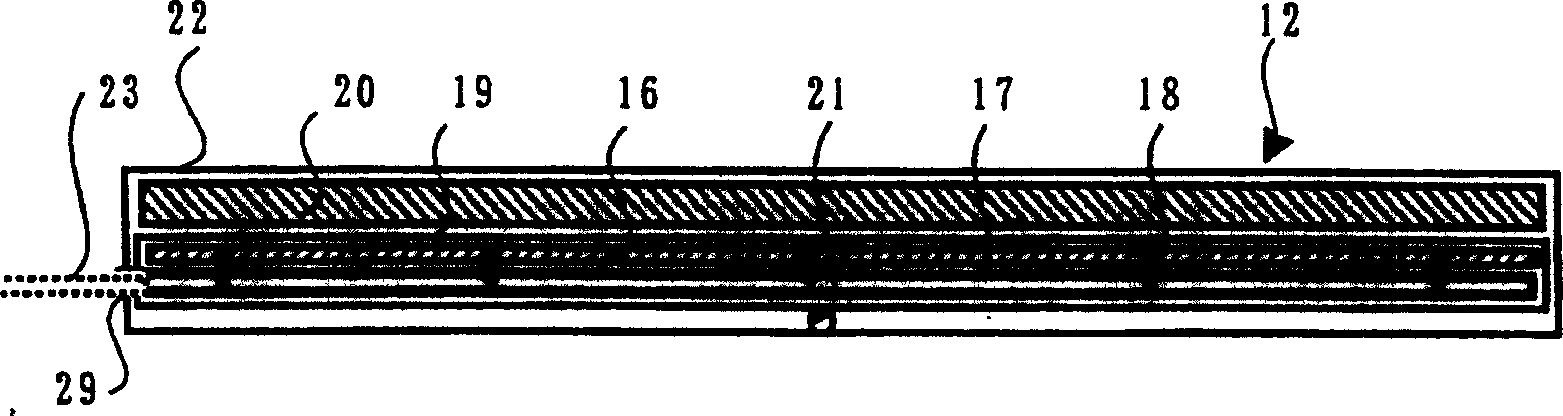

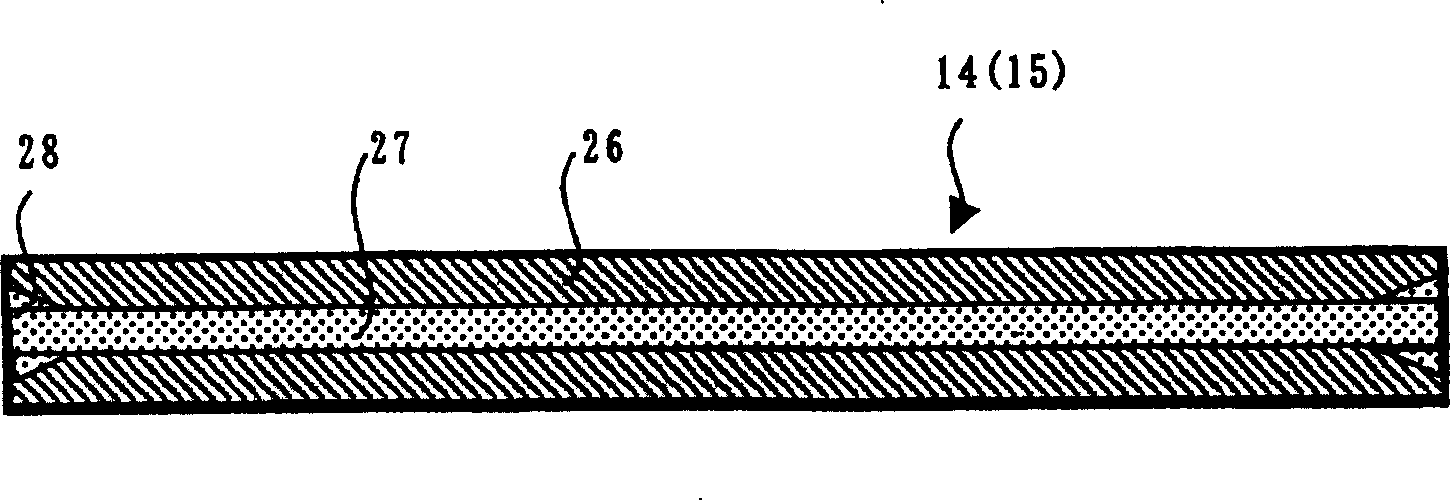

[0042] figure 2 It is an explanatory diagram of an example of the internal structure of the thermal insulation unit.

[0043] image 3 It is an explanatory diagram of an example of the notch shape of the corners of both pipe ends of the slit-shaped opening of the support cover and the outer cover.

[0044] Figure 4 It is an explanatory diagram of the procedure of attaching each component of the thermal insulation kit and the thermal insulation structure of the present invention, that is, the thermal insulation unit, the support cover, and the outer cover to the pipe.

[0045] Figure 5 It is an explanatory diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com