Assembling apparatus, assembling method and terminal cleaning apparatus

一种组装设备、清洁设备的技术,应用在清洁方法和用具、化学仪器和方法、用电元件组装印刷电路等方向,能够解决基板无法被送入、难以提高清洁步骤工作效率、妨碍缩短组装操作时间周期等问题,达到工作效率缩短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

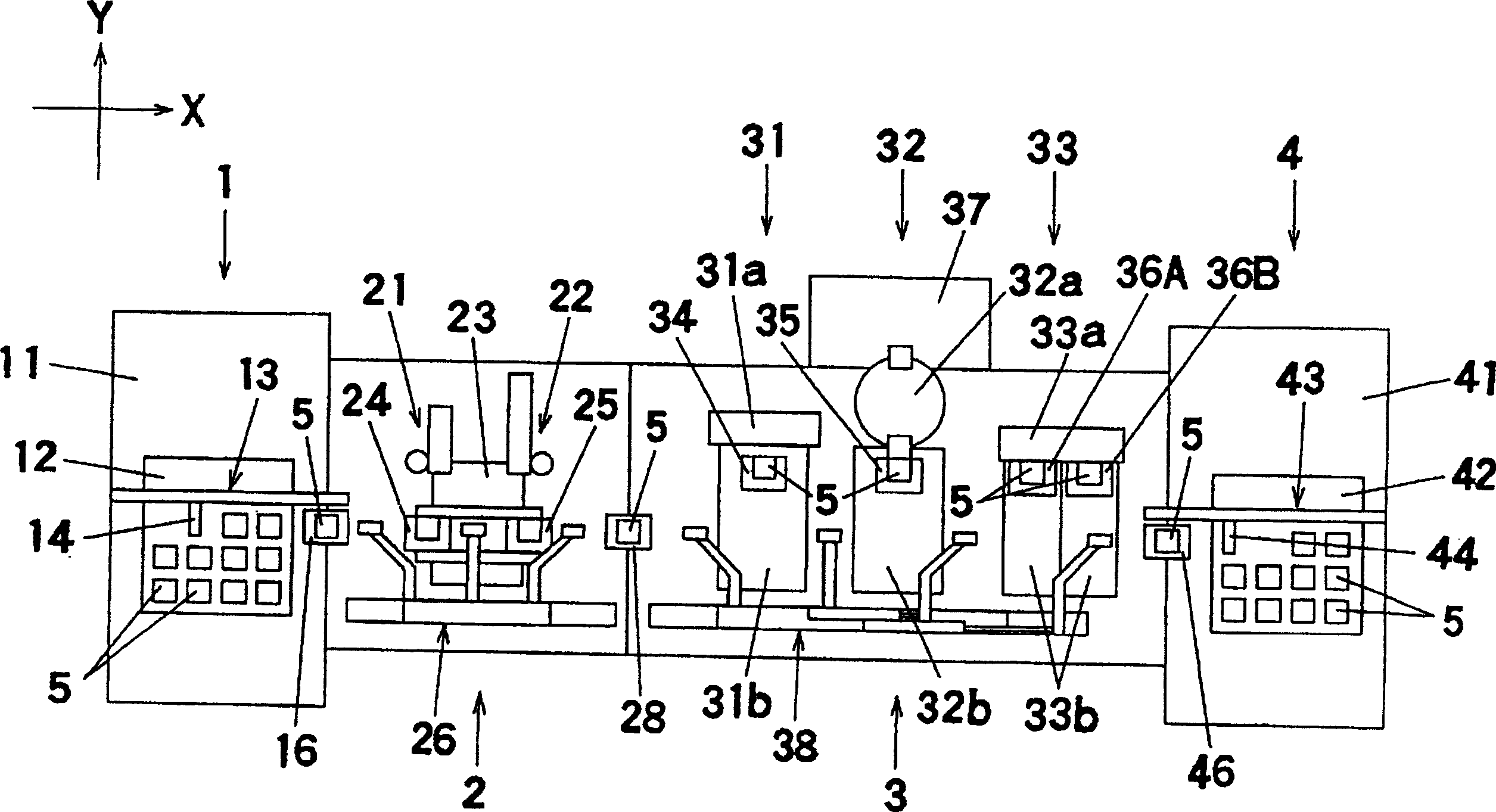

[0021] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0022] First, refer to figure 1 The overall configuration of an assembly apparatus for crimping electronic parts onto glass substrates in a display panel assembly operation will be described. exist figure 1 In, the assembly equipment passes from the upstream side ( figure 1 The left side of the board) is composed of a substrate supply part 1, a terminal cleaning device 2, an electronic component crimping device 3, and a substrate recovery part 4 in sequence. According to this display panel assembling operation, a glass substrate 5 constituting the main body of the display panel (hereinafter simply referred to as "substrate") is taken out from the substrate supply section 1, and the outer parts provided at the edge portion of the substrate 5 are cleaned using the terminal cleaning device 2. The connection terminal is cleaned, and thereafter, an electronic part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com