Water uptake expansion bag and preparation method

A water-absorbing swelling bag and a production method technology, which are applied in water conservancy projects, marine engineering, construction, etc., can solve the problems of tearing the buttonhole of the leak-stopping bag, drifting of the leak-stopping bag, and failure to exert the effect of the water-absorbing swelling bag. Achieve the effect of strengthening stability, firmness, uniform distribution and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention will be further described,

[0014] 1. The water-absorbing expansion bag is divided into inner and outer layers. The outer bag is made of plastic woven bag, and the inner bag is made of chemical fiber cloth bag. The length of the inner and outer bags is 80cm, the width is 50cm, and the height is 40cm. Equipped with 8Kg water-absorbing expansion agent.

[0015] 2. The water-absorbing swelling agent is composed of attapulgite clay, bentonite, anhydrous gypsum powder and super absorbent resin

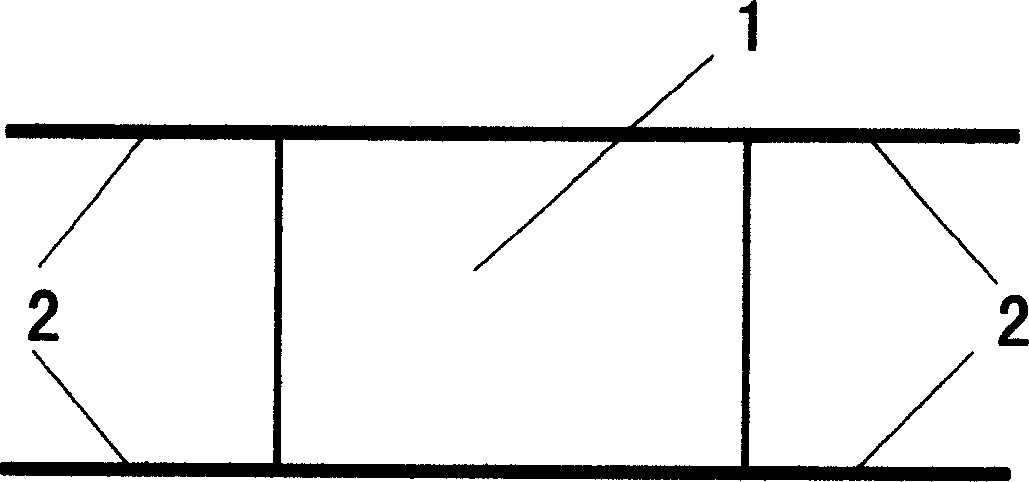

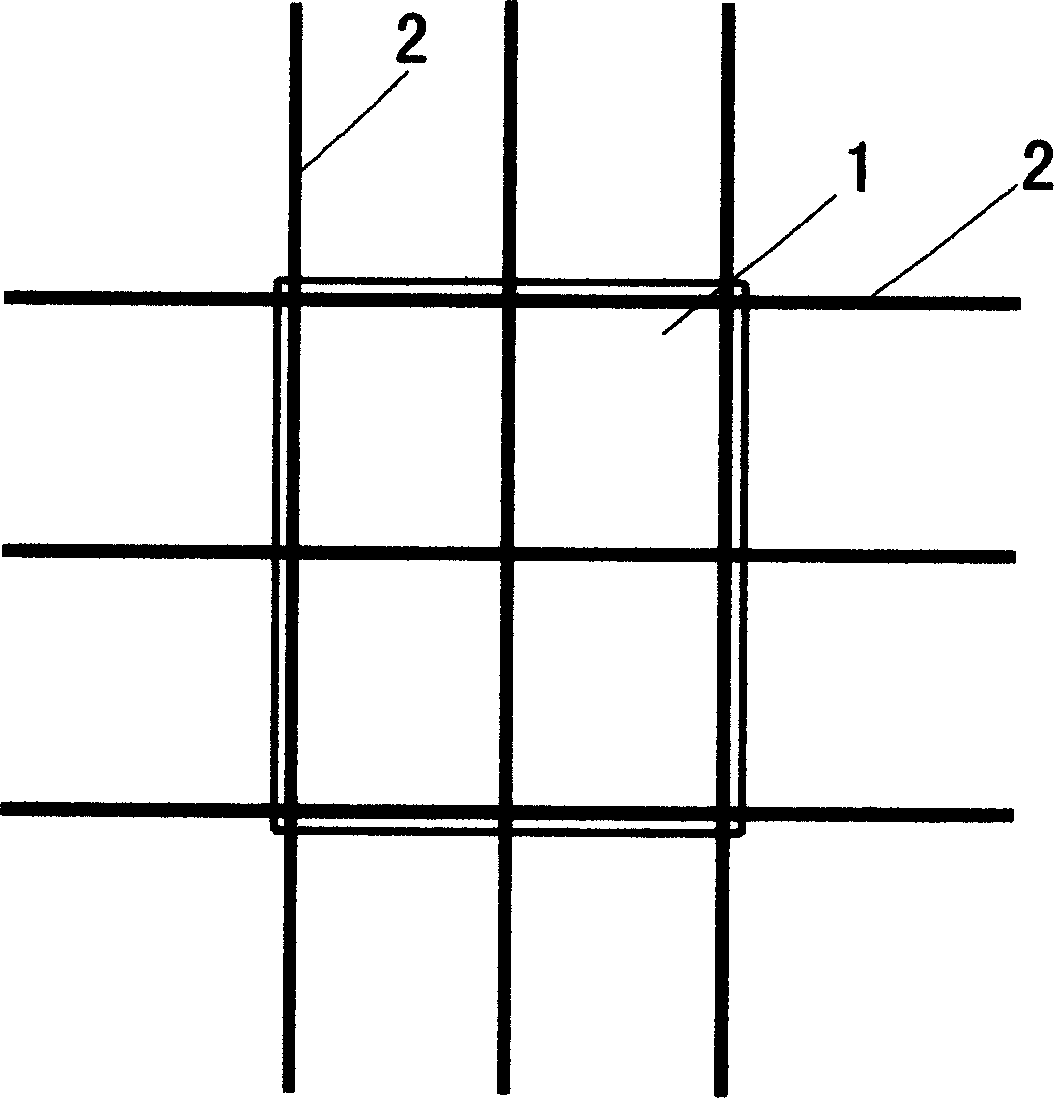

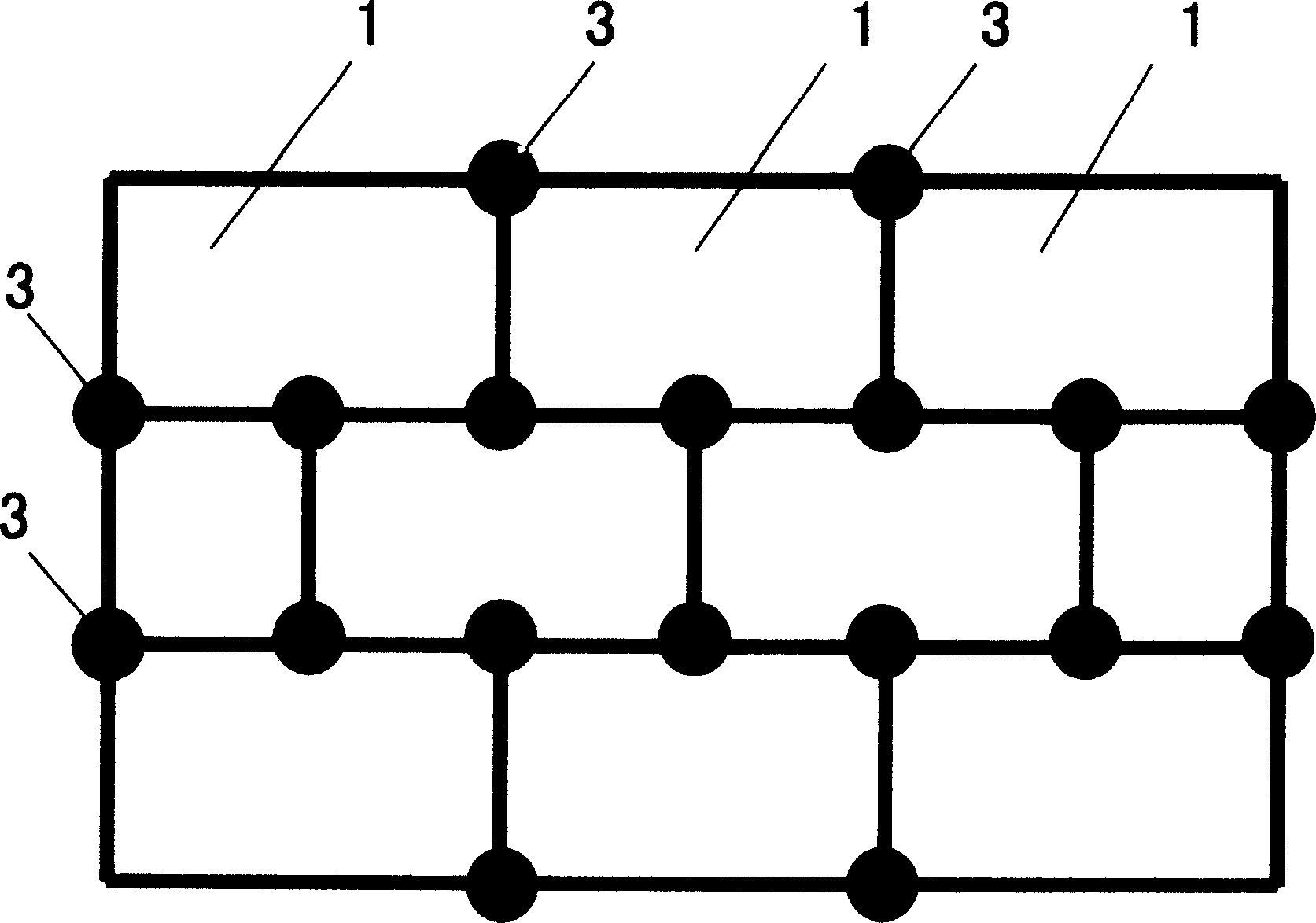

[0016] 3. On the upper and lower planes of the outer bag, 6 connecting straps are sewed for the tight connection between the outer bag and the outer bag, so as to improve the overall strength and water shock resistance of the water-absorbing swelling bag.

[0017] 4. When the water-absorbing swelling agent in the bag encounters water, the weight of the water-absorbing swelling bag will rapidly increase to more than 80Kg, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com