Removable local artificial tooth and its making method

A kind of denture and partial technology, applied in the field of removable partial denture and its production, can solve problems such as repair failure, achieve the effect of protecting abutment teeth and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

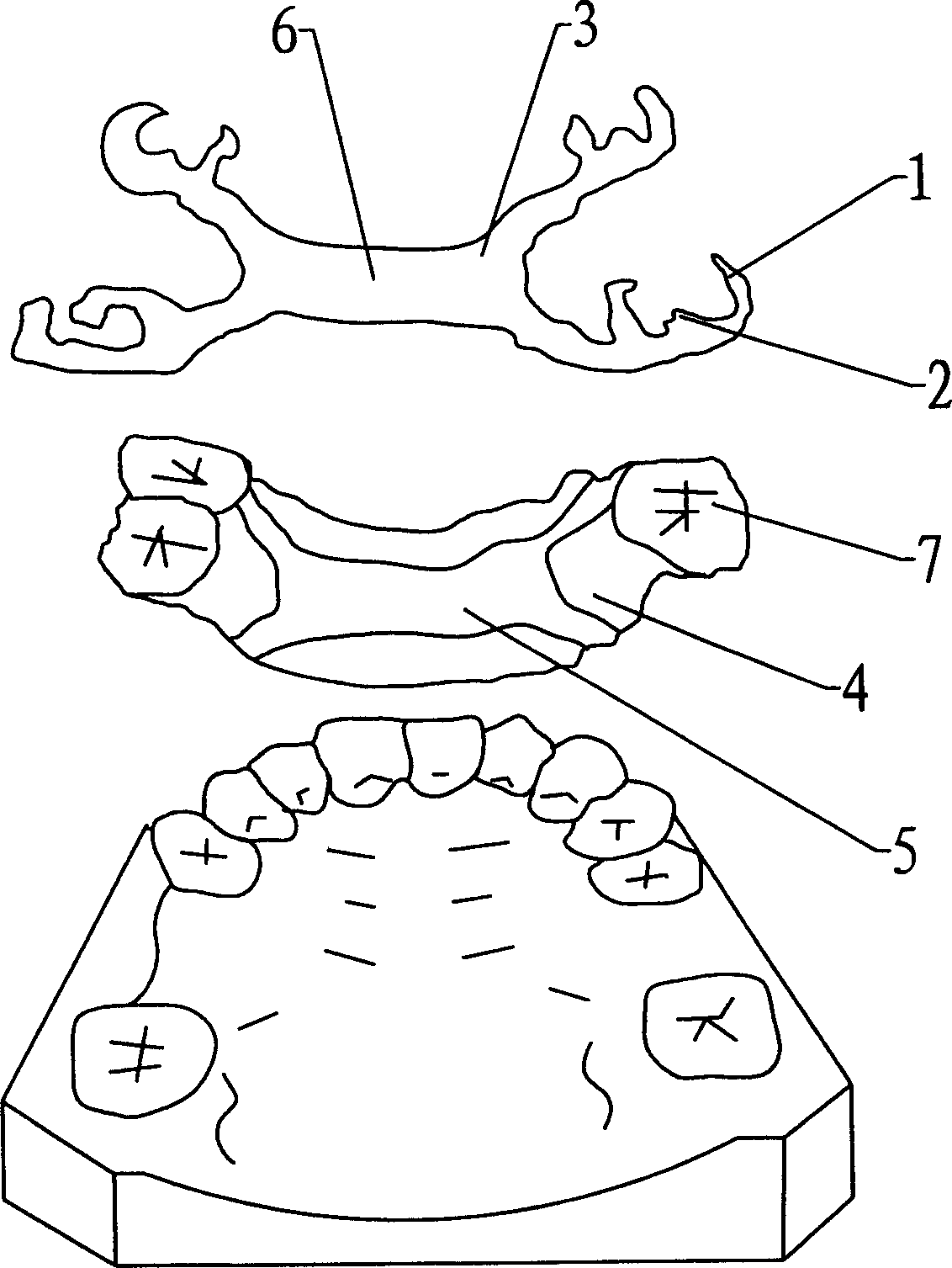

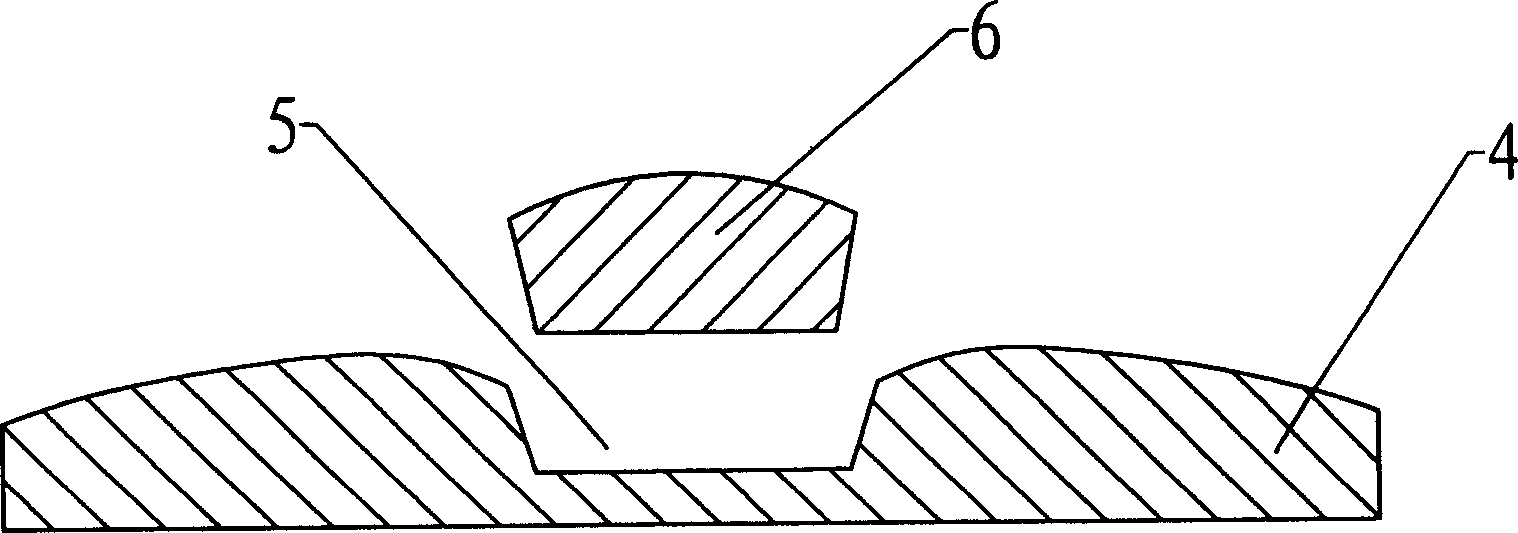

[0023] Such as figure 1 , figure 2 As shown, the removable partial denture of the present invention includes several basic functional parts such as a clasp 1, a rest 2, a base and an artificial tooth 7, and the base is composed of an upper base 3 and a lower base 4 stacked up and down , the upper base 3 and the lower base 4 are made of integral casting of alloy. The snap ring 1 and the rest 2 are arranged on the upper base 3, and directly contact with each abutment tooth, and play the role of retaining and holding, and maintain the stability of the artificial tooth 7 . The artificial tooth 7 is arranged on the retainer on the lower base 4, and the lower base 4 is in close contact with the oral cavity ridge and mucous membrane, and is attached with the artificial tooth 7, which acts as a force bearing for the artificial tooth 7. The contact part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com